XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD - Research, development, design, sale and service of ceramic components

China

Manufacturer/ Producer

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® PBN ceramic part includes the PBN Disc, PBN Sheet, PBN Filament Ring, PBN VGF Crucibles, PBN LEC Crucibles, PBN MBE Crucibles, PBN Conical Crucible, and Other PBN Machined Custom Parts. Molecular beam epitaxy (MBE) is a standard process for gallium GaAs crystal production, and PBN is the ideal material to make MBE crucibles. INNOVACERA® Performance Pyrolytic boron nitride properties are as below: Good thermal conductivity High insulation resistance High dielectric strength over wide temperature ranges Extremely pure Non-wetting Non-toxic Non-reactive to most other compounds Withstand high temperatures and rapid cooling

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® Hot Press Boron Nitride Rod Diameter 32 mm, two length in stock (25 mm, 100 mm), custom length is available. White in color. Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Features of Boron Nitride High thermal conductivity Low thermal expansion Good thermal shock resistance High electrical resistance Low dielectric constant and loss tangent Microwave transparency Non toxic Easily machined — non abrasive and lubricious Chemically inert Not wet by most molten metals

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Balls are widely used on bearings with extreme performance requirements, such as: High-speed bearings, high precision bearings, vacuum bearing, high / low-temperature bearing, non-magnetic bearing, high precision ball screw; it is also used as valve ball, measuring ball for the chemical pump, heat pumps, metering pumps. Its excellent properties including: Good corrosion resistance withstands attacks from harsh chemicals and environments. High-Temperature Hardness is twice that of steel, Silicon nitride ceramic balls retain their strength and hardness up to 1800 degrees F.Lightweight, silicon nitride ceramic balls’ density is 3.20g/cm3 and weighs 45% less than steel which reduces centrifugal force, skidding and wear under high speed and acceleration, so greatly extending the service life. Superior Surface Finish is conducive to improving working speed and reach higher accuracy.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

BAB299, BAB350, BAB492, BAB496, and BAB497 Ceramic Reflectors are Single Lamp & Single Rod, the external shapes are Elliptic. Ceramic Reflector is made of high purity porous alumina ceramic of 99% Al2O3 content, used extensively for long-life laser reflectors. This material is sintered at high temperatures to achieve a controlled porosity. Ceramic reflectors work particularly well in Ruby and Nd:YAG laser pumping chambers and can be a highly cost-effective alternative to metal-coated reflectors. They are also used extensively as reflectors in housings for high-intensity lamps. – Resist chemical attack – high strength – high reflectivity over a broad wavelength band – good thermal conductivity and electrical stability

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

BAB192 (TCT97, BAB349), BAB275, BAB330 Ceramic Reflectors are Single Lamp & Single Rod, the external shapes are Round. Ceramic Reflector is made of high purity porous alumina ceramic of 99% Al2O3 content, used extensively for long-life laser reflectors. This material is sintered at high temperatures to achieve a controlled porosity. INNOVACRA supplies ceramic reflectors for Lamp-pumped Solid-state Lasers, Diode-pumped Solid-state Lasers, and Beauty and IPL Applications. Here is our catalog for your reference. If you’re interested, please don’t hesitate to contact us for drawings and quotations.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

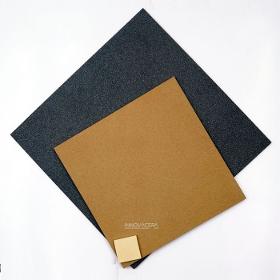

Innovacera uses its deep ceramics expertise and process capabilities to manufacture ceramics with precisely controlled porosity. Porous ceramics are often used for chemical filtration and fluid separation. The range of Innovacera porous ceramics is made from aluminum oxide and silicon carbide. The strong, uniform porous ceramic has 40-50% open porosity with a tortuous pore structure and is available in pore sizes ranging from 1 to 100 microns. Three Main Application of Porous Ceramic: Vacuum Chuck, like scribing machine vacuum chuck, silicon wafer vacuum chuck. Adsorption platform. Suspension platform. Especially, they are widely used for the semiconductor industry, like LED wafer processing. The micro-porous ceramic working disk is a special tool for adsorption and bearing in various semiconductor wafer production processes, and is applied to processes such as thinning, dicing, cleaning, and handling.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera supply the Alumina Porous ceramic disc for Vacuum Chuck which is mainly used to support and chuck the semiconductor wafer when grinding and dicing. It is applied in the process of thinning, dicing, clearance, transportation, and so on. Main Application field: — New and refurbished alumina porous ceramic chucks for Disco, ADT, K & S, Applied materials TSK, OKAMOTO, Micro Automation, Load Point, etc dicing saws and grinders. — 6″, 8,” 12″ are regular sizes, And pore size include 15 um, 30 um, 50 um, 100 um. Materials are alumina (Color: white, light brown, dark brown, blue-gray) — Custom size (like square, oval shape, or irregular shapes) is available for us. Characteristics include: High flatness and parallelism Compact and uniform microstructure with high strength Good permeability and uniform adsorption affinity Long life time Dressing easily.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Our knife can smooth the edge and remove sprayed points and separation lines from mold halves. Furthermore, it is a cabinet and easy to use to avoid injury. Different kinds of blades can be replaced so that the cost is effective. Features: 1, Faster cutting rates 2, Consistently good cutting quality, e.g. improved strength of spliced connections 3, No corrosion 4, Smooth running 5, Extended maintenance intervals 6, Universal cleaning possibilities using acids, alkaline solutions, and organic solvents Application Our cutter is ideal for removing the burrs of plastic, metals, rubber, and so on.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® Ceramic hot surface igniters for pellet boilers only need approx. 1/10 of the energy needed by hot air fans and ignition blowers. Their ignition capacity lies between 120 and 350 W. Depending on the positioning of the ignition element in the boiler, the ignition time of approx. 60 seconds is extremely short. This also means minimal emissions. Specification: Voltage: 120V/230V Power: 160 W, 180 W, 210 W, 225 W, 230 W, 240 W, 255 W Tube Size: OD10.5 × ID6.5 × L90 mm Supporting Socket: NO.4/NO.5/NO.6/NO.29 Lead wire: 300mm/400mm/500mm/900mm (Customized is accept) Range of temperature: 800~1100 °C Ceramic igniter technology benefits: A fraction of the energy consumption compared to conventional cartridge or element heater. Long-lasting (non-aging). Time to ignition 60~90 seconds. Tested to 100,000 cycles. Easy to install and retrofit. 800~1100°C at steady-state temperature. Impervious to oxidation and corrosion.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® Ceramic hot surface igniters for pellet boilers only need approx. 1/10 of the energy of that needed by hot air fans and ignition blowers. Their ignition capacity lies between 120 and 350 W. Depending on the positioning of the ignition element in the boiler, the ignition time of approx. 60 seconds is extremely short. This also means minimal emissions. Specification: Voltage: 120V / 230V Power: 300W / 350W Tube Size: OD11.5 × ID6.5 × L108 mm Supporting Socket: NO.43 Lead wire: 300mm / 400mm / 500mm / 900mm (Customized is accept) Range of temperature: 800~1100 °C Applications: Kerosene fan heater Wood pellet, wood chips stove or boiler Small scale biomass industrial furnace ignition Incense burner

Request for a quoteManufacturer/ Producer

Block A, 6/F, No.588 Jiahe Road,

Torch high-tech industrial district, xiamen, china 3610

361006 Xiamen - China