- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bending capacity

Results for

Bending capacity - Import export

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites: a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality. Tube measurements up to 60 mm, up to 80 mm and up to 115 mm are covered, depending on the machine. It is also feasible to bend tubes with imperial sizes with the standard tools.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

Established in 1959 and with particular emphasis on hydraulic bending rolls since the early 1980’s, MG are world leading manufacturers of plate bending machines. The current range is the result of continuous research and development over the years and represents the highest level of technology in this field. With capacity to manufacture machines in the range of 200mm to 8000mm bending length and 1mm to 300mm bending capacity, MG has a solution for virtually every requirement. The 4-Roll ‘Series M’ models are of double pinch design, with additional bottom roll, and have been produced using high quality components, benefiting from MG’s proven technology, allowing maximum performance while still requiring little maintenance over the life of the machine. The 4-Roll design, with continuous pinching of the material, provides the option of fitting an NC or CNC control, therefore allowing the automation of the bending process.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The Curvassi range of rotary tube bending machines have been designed for high quality bending of both metric and imperial tube sizes with a wall thickness sufficient to bend without a mandrel. Tooling can be supplied any tube diameter within the capacity of the machine and in a variety of centre line radii. Three models are available with tube bending capacities of up to 60mm, 76mm and 114mm diameter, based on mild steel tube.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The CBC tube bending machines range from ‘easy to use’ simple machines to precision programmable production machines. A comprehensive tooling range ensures high bend quality on all models. All formers can be specified with either counter formers or guide rollers depending on material and wall thickness. Optional equipment includes moving arm with positioning stops and plane of bend indicator. The new large capacity CBC UNI 89 can effortlessly bend 88.9mm x 8mm wall mild steel tube.

Request for a quote

SHAPEYOURGLASS

Belgium

In the automotive industry, dashboard, and interactive screens are fairly important as they play a big part in the overall design of the car. We provide extrathin glass with cold bending capacities (as pictured), fitting the curve of your design. In other types of transportation, our service can play a valuable part as well (planes, trucks, boats...).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POUGET

France

USE : Bending of the rails on Tracks ("Vignole" Rails) and Grooved Rails (See the OPTIONS) ADVANTAGES : Pratical and Tough - Control Level Requires without effort. "Vignole" Rail Bending until 60 Kg/m. - Ref. 35-T - Bending Capacity 35 Tons - Mechanically soldered Body - Shapes suitable for each type of rail - Integrated Pump and Oil Tank - Activated Operating Lever, Length 1 m - Automatic Rapid Return Central Piston - 4 Handles - Paint yellow varnish - Stroke : 80 mm - Dimensions : 68 x 67 x 25 cm - Net Weight : 125 Kg OPTIONS : Grooved Rail Bending (Tramways Rails), until 75 Kg/m. - Ref. 60-T - Bending Capacity 60 Tons - Stroke = 100 mm - Shapes suitable for each type of rail - Dimensions : 93 x 84 x 29 cm - Weight = 220 Kg

Request for a quotePOUGET

France

USE : Bending of the rails on Tracks ("Vignole" Rails) and Grooved Rails (See the OPTIONS) ADVANTAGES : Pratical and Tough - Control Level Requires without effort. "Vignole" Rail Bending until 60 Kg/m. - Ref. 35-T - Bending Capacity 35 Tons - Mechanically soldered Body - Shapes suitable for each type of rail - Integrated Pump and Oil Tank - Activated Operating Lever, Length 1 m - Automatic Rapid Return Central Piston - 4 Handles - Paint yellow varnish - Stroke : 80 mm - Dimensions : 68 x 67 x 25 cm - Net Weight : 125 Kg OPTIONS : Grooved Rail Bending (Tramways Rails), until 75 Kg/m. - Ref. 60-T - Bending Capacity 60 Tons - Stroke = 100 mm - Shapes suitable for each type of rail - Dimensions : 93 x 84 x 29 cm - Weight = 220 Kg

Request for a quote

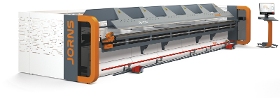

JORNS AG

Switzerland

The fully automatic Jorns JDB double bending machine can be configured in lengths of 3.2 to 12.2 metres and with a bending capacity for sheet metal up to 3 mm. It increases the speed of your projects – and awakens the desire to create something bigger. The simultaneous bending of complex profiles poses no problem for the Jorns JDB double bending machine because multitasking is a given. The area behind the clamping tool with a retraction of over 290 mm for the bending tools offers above-average open space. You can then produce bending profiles without turning them around or over – with an array of possible profile variations. Several parallel, tapered or overlapped profiles can be bent simultaneously, an innovation that increases the speed of your work. The use of servo-technology, the automatic loading and unloading table as well as the individually driven clamping fingers allow maximum precision, flexibility and productivity. Thanks to two bending tools, material handling has also be

Request for a quote

JORNS AG

Switzerland

The semi-automatic Jorns JB bending machine can be configured in lengths of 3.2 to 12.2 metres and with a bending capacity for sheet metal up to 3 mm. It offers a great deal of freedom – and not only when it comes to the clamping tool. The area in front of and behind the clamping tool of the Jorns JB bending machine offers above-average open space, letting you manufacture bending profiles extremely efficiently. The use of servo-technology and the stop fingers that can be moved freely on the sides guarantee maximum precision and flexibility to bend parallel, tapered or overlapped profiles. A successful bend and subsequent installation of your profiles is down in no small part to the consistent calculation of processing and stop positions according to the “Shorten bending according to DIN 6935” method, intuitive graphic programming, the high level of angular accuracy and the uniformly closed water folds. Ultimately, what the JB gives you is time – time for more freedom and new ideas in

Request for a quoteResults for

Bending capacity - Import exportNumber of results

10 ProductsCompany type