- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- food grade mixer

Results for

Food grade mixer - Import export

ARPA INCORPORATED COMPANY

Greece

Food grade big bags are manufactured under BRC certified facilities that meet the requirements for both GFSI (Global Food Safety Initiative) and companies involved in the food and pharmaceutical sectors. All our food grade big bags are manufactured from 100% virgin polypropylene material which meets FDA food grade requirements.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

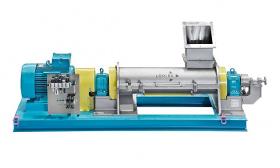

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. The continuous process can be run at filling levels between 20 % and 50 % without influencing the mixing quality. Choppers can be additionally installed in the mixing drum.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The CoriMix® is a high-speed, continuous mixer for high throughputs, especially developed for homogeneous mixing of liquid and pasty components into dry substances. The system is based on the high peripheral speed of the mixing shaft tools of up to 50 m/s. The product is moved through the mixing chamber in a plug-flow manner. The retention time is extremely short compared with a continuous ploughshare mixer. The mixing chamber is divided into zones with different mixing tools enabling different shear intensity by selecting and adjusting the mixing tools according to each application. Liquid components are introduced directly into the product ring layer – either via tangentially placed liquid pipes through the drum wall or via a hollow mixing shaft with specially perforated tools. However, moistening of the mixer wall and shaft is largely prevented. The liquid distribution is similar to a nozzle but avoiding any risk of clogging or disturbance of the spray.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels on the mixing shaft in a horizontal, cylindrical drum rotate to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. Thanks to their form adapted to individual application and the speed adjustment, Lödige ploughshare mixers can be used for a wide range of applications. Choppers can be additionally installed in the mixing drum to increase the turbulence in the mixing process. This ensures the mixing of fine particles in small quantity and enables the dispersion of these products .

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The application range includes everything from processing of viscous components to paste-like products with poor flow. The range of food applications is exceptionally broad and there are also various applications for the pharmaceutical industry. The conical shape permits thorough residue-free discharge. The wet mixer system is a vertical mixing system for batch processes. The geometry of the conical or cylindrical mixing vessel, the arrangement and shape of the tools and their peripheral speed are adapted to each other in all sizes, resulting in effective mixing of all components. Depending on the process engineering tasks, the individual mixing tools are combined to form one tool both for material transport and for dispersion and disagglomeration processes. The installation height in the vessel is adjustable within a wide range. An adjustable deflector can be used to affect the product movement in a systematic fashion.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZHONGSHAN LVHANG ELECTRIC CO., LTD.

United States

stand food mixer ABS Housing Power:1000W Stainless Steel Bowl With 5L Switch: 6 speeds With LED light With Egg beater With Dough hook With Flat beater

Request for a quoteResults for

Food grade mixer - Import exportNumber of results

7 ProductsCountries

Company type