- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- compressors

Results for

Compressors - Import export

OPEN GRID EUROPE GMBH

Germany

Maintenance and repair work on the natural gas network is generally carried out with the pipeline being gas-free, so the relevant pipe sections are isolated by installing valve assemblies and the gas in the isolated section is vented to atmosphere. By using our mobile compressors – individually or in highly efficient parallel operation – the network operator can transfer the gas from the isolated pipe section to another part of the system so it does not have to be vented to atmosphere. Connection points for the mobile compressors are available e.g. in the area of the main line valves or can generally be retrofitted. It makes economic sense to transfer the gas to another as this guarantees responsible handling of this primary energy source and makes a substantial contribution to protecting the environment. Services offered: Pipeline recompression until lowest residual pressure < 3bar Reduction of methane emissions by up to 95% Responsible handling with primary energy

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

Synthetic high performance compressor oil CE 850XC Alusynt for air compressors. Available from stock in 1 ltr. container.

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

High quality filling adapters made from corrosion resistant stainless steel for filling breathing bottles of escape equipment (EEBD) to be connected to a conventional 200bar connector.

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

High quality filling adapters made from corrosion resistant stainless steel for filling breathing bottles of escape equipment (EEBD) to be connected to a conventional 200bar connector.

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

High quality filling adapters made from corrosion resistant stainless steel for filling breathing bottles of escape equipment (EEBD) to be connected to a conventional 200bar connector.

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

Pressure reducer 300/200 bar A pressure regulator for filling 200 bar compressed air bottle with a 300 bar connector. The high-quality pressure reducer consists of corrosion-resistant, massive V2A- housing, robust DIN- valve (approved in compliance with EN 144) and has an overpressure valve (response pressure: 225 bar) No modification of compressor necessary! Datenblatt

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

We also distribute all spare parts for breathing compressors of Coltri and Bauer: filling connector sets coupling for hose manometer up to 400 bar T- connection part Suction tube V-belt Gasket sets Safety valve Valve spring Piston pin Drive motor ..and many more

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

The mobile breathing air compressor Bauer JUNIOR II is the most compact compressor of all. Made of long-lasting, proven and reliable materials and components this compressor convinces with an average performance of 100 litres per minute as gasoline-powered and three-phase- or alternating current device. The device meets all requirements according DIN EN ISO 9001. Breathing air is cleaned according to DIN EN 12021(former DIN 3188) The high-quality compressor Junior II is a result of 60-years know-how and is still produced in Germany. Technical Data: JUNIOR II – B (fuel) Operating pressure: max. 330 bar Delivery quantity l/min: 100 Speed min-1 :2300 Filling time min: 2 Motor kW (PS): 4,0 (5,5) Filter system TRIPLEX® : P21 Dimension approx. cm ( L x B x H): 78 x 34 x 42 Weight net: approx. 44 kg

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

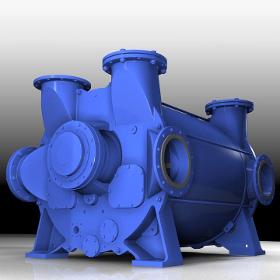

100 - 3600 CFM / 170 to 6,100 m³/h The NASH SC can be found in countless industries, performing its duties. Available in nine models, the capacities of the NASH SC compressor range from approximately 100 CFM to 3,600 CFM and up to 25 PSIG. NASH SC compressors come in iron & stainless steel.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

3000 - 16000 CFM / 5,100 to 27,200 m³/h The NASH 904 , which replaced the popular NASH CL pump in the 1980's, can still be found at Gardner Denver Nash. Capacities of the 904 pumps range upward from about 3,000 CFM at vacuum. These durable pumps can handle excess liquid carryover without any difficulty, even if it arrives as massive slugs. 904 pumps are found in many industries including Paper, Chemical, and Mining. All 904 models are still available from Gardner Denver Nash, the original designer and manufacturer. Whether you have an existing 904 pump running in your plant that is in need of service, repair, or replacement with a new or remanufactured duplicate 904/905 pump, Gardner Denver Nash is there for all of the above.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

100 - 1800 CFM / 170 to 3,050 m³/h The GARO line of liquid ring compressors expands the capacity and pressure ranges of the Nash line to meet the ever growing requirements of our customers. Found primarily in petroleum refineries and chemical plants, these rugged and reliable compressors handle highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and Vinyl Chlorine Monomer (VCM) recovery. The GARO line, available in single and two-stage designs, comes in: cast iron, stainless steel, carbon steel, spheroidal cast iron, 316 stainless steel, duplex stainless steel, and Hastelloy or Titanium on select models. Together with other NASH liquid ring compressors, including the HP-9, the 14 GARO models form the NASH core compressor product line, which provides compression greater than 200 psig (15 Bar abs). Low pressure compressors are available to 30 psig (3 Bar abs), and 20,000 CFM (34,000 m³/hr). As a result, NASH offers the widest pressure and capacity ranges of liquid ring compressors available worldwide.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

3000 - 16000 CFM / 5,100 to 27,200 m³/h The NASH 905 is a redesign and upgrade of the NASH 904. Capacities of the 904 pumps range upward from about 3,000 CFM at vacuum. These durable compressors can handle excess liquid carryover without any difficulty, even if it arrives as massive slugs. 904 compressors are found in many industries, including Paper, Chemical, and Mining. The 905 series has been designed to provide superior reliability and performance in harsh applications such as chemical processing or geothermal power generation. Constructed of 316L stainless steel, the 905 series offers excellent corrosion resistance and can be outfitted with a variety of mechanical seals. It also includes a patented gas scavenging feature.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 6,000 to 11,00 m³/h The NASH 2BQ1 590 has a unique performance range. It combines a high gas flow rate (6,000 to 11,000 m³/h) with a discharge pressure range of up to 3.75 bar abs. The standard 2BQ compressor model is equipped with a duplex steel shaft, ductile iron end shields, a massive stainless steel housing and o-rings to seal housing components. Higher quality materials are available on demand by using the modular 2BE3/4 design. The NASH 2BQ1 is certified for ATEX.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The NASH 2BE5 was developed from the proven NASH 2BE3 and 2BE4 compressors, whose reliable performance has been further improved. The development focused on optimizing performance, higher vacuum capabilities and ease of maintenance. NASH 2BE5 Benefits include: improved efficiency higher vacuum levels (to 100 mbar abs / 3" Hg abs) built-in ECO-FLO™ water saving technology with patent pending gas scavenging drop in replacement for 2BE3 and 2BE4 removable bearing brackets for easier maintenance elimination of tie rods, resulting in improved sealing due to bolted casing joints polyisoprene lining The footprint and connections to the NASH 2BE5 models are identical to its predecessors, the NASH 2BE3 and 2BE4. Therefore, exchanging or upgrading to the more efficient NASH 2BE5 requires no site modifications. The NASH 2BE5 model is available in cast iron, with stainless steel coming soon. The 2BE5 is perfect for use in mining, filter applications, paper mills, power plants, chemical plants, refineries and more.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

1500 - 19000 CFM / 3,000 to 9,500 m³/h Nash's 2BE3 and 2BE4 series compressors have capacities ranging from 1,500 to 19,000 CFM (2,500 to 33,000 m³hr). Designed to operate in demanding environments like the paper, power, mining and chemical process industries, these compressors offer durability and reliability at a low cost of operation. Each model is equipped with an application-proven polyisoprene-lined body for added corrosion & erosion resistance. The unique inlet configuration allows for both top and side inlet arrangements to accommodate low headroom installations. In installations where space is limited, the top discharge capability of the 2BE3 and 2BE4 allows the use of a top mounted discharge separator that saves floor space and eliminates the need for a trench. These compressors allow efficient operation over the entire vacuum range without the need to change the compressors's internals. When equipped with a center shroud, split vacuum operation up to 12 in. Hg (400 millibar) differential can be achieved. Large inspection ports allow easy access to pump internals for inspection and maintenance. For more aggressive applications, stainless steel, stainless steel clad and epoxy coated components are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

120 - 5300 CFM / 195 to 9,000 m³/h The NASH Vectra was designed around a modular platform using the most advanced computer aided design techniques, such as 3D solid modeling and finite element analysis (FEA). The modular platform offers the advantage of two versions with numerous common parts. The Vectra GL model, available from 120 to 830 CFM (200 to 1,500 m³/hr), is ideal for general industrial applications. It comes standard with internal mechanical seals and many Nash patented innovations including gas scavenging. The Vectra XL model was designed to meet the stringent requirements of many CPI applications. Whether operating as a vacuum pump or compressor, it features a 30 PSI (2 bar) differential capability. It is available in ductile iron or 316L stainless steel with a variety of shaft sealing options. Sizes range from 120 to 5,300 CFM (200 to 9,000 m³/hr). The NASH Vectra can be operated within a wide range of operating speeds, with numerous 50 and 60 HZ direct drive speeds. This increased turndown capability makes them ideal for varying load applications when driven by VFD's.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

This rugged and reliable liquid ring compressor expaned the NASH Vectra compressor range with a model that operates at up to 4 bar G (60 PSIG). The XM-150 comes in 681 and 682 compliant versions and is specifically designed for the higher pressures and performance requirements found in many process applications, including vapor recovery, flare gas recovery, biogas, corrosive gas handling (e.g. VCM and chlorine) and hydrogen compression. The NASH Vectra XM-150 liquid ring compressor provides the same quality and reliability you've come to expect from the existing Vectra series with these features: Single, conical port design; Between bearing rotor/shaft design; single pressure boundary sealing point; API-681 and API-682 category II/III compliance; increased bearing life; 316 stainless steel construction; and horizontal, self-draining inlet/discharge nozzles. The rugged construction and easy to service design of this liquid ring compressor reduces maintenance requirements and minimizes downtime for maintenance and repairs in even the most demanding applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

1800 - 2600 CFM / 3,050 to 4,400 m³/h Found primarily in petroleum refineries and chemical plants, this rugged and reliable compressor handles highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and Vinyl Chlorine Monomer (VCM) recovery. Together with the 14 new GARO models and other NASH liquid ring compressors, the NASH HP-9 compressor form the NASH core compressor product line, which provides compression greater than 200 psig (15 Bar abs). Low pressure compressors are available to 30 psig (3 Bar abs), and 20,000 CFM (34,000 m³/hr). As a result, NASH offers the widest pressure and capacity ranges of liquid ring compressors available worldwide.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 125 to 1400 m³/h; Vacuum to 33 mbar abs.; Discharge pressure to 2.0 bar abs. The NASH 2BM1 magnetic drive pump series is capable of achieving volume flow rates of 125 to 1400 m³/h and vacuum of 33 mbar abs. Non-contact torque transmission is achieved by using a permanent magnetic drive system. The pump's inner working space is hermetically sealed from atmospheric conditions, eliminating any possibility of leakage. This seal is essential for demanding applications, such as processes that are required to meet the most stringent standards on environmental compatibility. ATEX applications are also possible, certifications are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 125 to 1400 m³/h; Vacuum to 33 mbar abs.; Discharge pressure to 2.0 bar abs. The NASH 2BM1 magnetic drive pump series is capable of achieving volume flow rates of 125 to 1400 m³/h and vacuum of 33 mbar abs. Non-contact torque transmission is achieved by using a permanent magnetic drive system. The pump's inner working space is hermetically sealed from atmospheric conditions, eliminating any possibility of leakage. This seal is essential for demanding applications, such as processes that are required to meet the most stringent standards on environmental compatibility. ATEX applications are also possible, certifications are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

100 - 3600 CFM / 170 to 6,100 m³/h The NASH SC vacuum pump and compressor, which replaced the popular NASH CL pump in the 1980's, is still being manufactured at Gardner Denver Nash. The SC pump, more flexible and simpler to install and easy to maintain, made it a very reliable pump to be used in many applications. SC pumps are found in applications including: autoclaves, chucking, container filling, labeling and forming, cooking, deaerating, deodorizing food and fats, drying, evaporating, eviscerating, exhausting, extruder venting, fiber setting, filtering, forming, gas stripping, laboratory central vacuum systems, medical and dental vacuum draining, molding, pickup and conveying, priming, slot extraction, and solvent recovery. All SC models are still available from Gardner Denver Nash, the original designer and manufacturer. Whether you have an existing SC pump running in your plant that is in need of service, repair, or replacement with a new or remanufactured duplicate SC pump, Gardner Denver Nash is there for all of the above.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

170 - 14000 CFM / 240 to 23,700 m³/h The NASH CL Vacuum Pump and Compressor product line is perhaps the most popular ever built. There are 12 different models, from the CL-200 through the CL-14000, with capacities ranging from 150 CFM to over 14,000 CFM. They can be found in many applications including: autoclaves, carburetor testing, chucking, condenser exhausting, container filling, cooking, deaerating, drying, eviscerating, exhausting, extruder venting, fiber setting, filtering, forming, gas stripping, molding, pickup and conveying, priming, slot extraction, and solvent recovery. All CL models are still available from Gardner Denver Nash, the original designer and manufacturer. Whether you have an existing CL pump running in your plant that is in need of service, repair, or replacement with a new or remanufactured duplicate CL pump, Gardner Denver NASH is there for all of the above. Gardner Denver Nash continues to manufacture and offer the CL to our customers.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

3000 - 16000 CFM / 5,100 to 27,200 m³/h The NASH 904 , which replaced the popular NASH CL pump in the 1980's, can still be found at Gardner Denver Nash. Capacities of the 904 pumps range upward from about 3,000 CFM at vacuum. These durable pumps can handle excess liquid carryover without any difficulty, even if it arrives as massive slugs. 904 pumps are found in many industries including Paper, Chemical, and Mining. All 904 models are still available from Gardner Denver Nash, the original designer and manufacturer. Whether you have an existing 904 pump running in your plant that is in need of service, repair, or replacement with a new or remanufactured duplicate 904/905 pump, Gardner Denver Nash is there for all of the above.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

18 - 75 CFM / 30 to 127 m³/h Innovative and economical monoblock pumps The NASH 2BV7 pumps have been designed to provide superior performance for a wide array of applications. Available from 18 to 75 CFM (30 to 140 m³/hr), their high vacuum capability, extra water handling ability and compact size combine to make an ideal machine for industries like plastics manufacturing and medical technologies. Combining quality construction with reliability The simple construction and quality materials of the 2BV7 combine for an extremely reliable machine. Featuring a corrosion free compression chamber that includes a stainless steel body, shaft and port plate, these pumps provide excellent resistance to to corrosive and errosive media. Whats more, with the corrosion free materials, the one moving part (the rotor) is ensured to turn freely even after long periods of inactivity. For worldwide use and available for quick delivery. The 2BV7 is equipped with a very versatile motor that is ready to be installed nearly anywhere throughout the world. The motor includes wide voltage range capability, an IP55 enclosure and is suitable for 50/60 Hz service. It also comforms to international standards, including UL and CSA. Providing a motor designed for the global market ensures that the 2BV7 is available when you need it, whether here or abroad.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

High capacity monoblock pumps Available in both cast iron and stainless steel construction, the 2BV5 family provides up the 600 m³/hr (360 CFM) in a compact monoblock design. Space-saving installation When compared to conventional pumps, the 2BV5's monoblock design delivers the benefits of a simple, compact and economical intallation. Since the pump and motor are integral and self supporting, there is no need for additional baseplates, couplings or guards, which add to the cost, complexity and overall size of the installation. Rugged and reliable We focused on durability and dependability when we developed these liquid-ring pumps. With a reinforced stainless steel shaft and sealed bearings, the 2BV5 can provide up to 20,000 hours of maintenance-free operation. Additional features such as the iron pump's ceramic coated casing prevent wear and ensure constant performance, even under harsh conditions. Quiet and precision balanced The 2BV5 is expertly designed and manufactured to be quiet and vibration free. With sound pressure levels of less that 75 dBA, it complies with the strictest noise standards, eliminating the need for additional sound attenuating devices.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

1500 - 19000 CFM / 2,500 to 33,000 m³/hr Nash's 2BE3 & 2BE4 vacuum pump series offers capacities ranging from 1,500 to 19,000 CFM (2,500 to 33,000 m³/hr). Designed to operate in demanding environments like the paper, power, mining and chemical process industries, these pumps offer durability and reliability at a low cost of operation. Each model is equipped with an application-proven polyisoprene-lined body for added corrosion & erosion resistance. The unique inlet configuration allows for both top and side inlet arrangements to accommodate low headroom installations. In installations where space is limited, the top discharge capability of the 2BE4 allows the use of a top mounted discharge separator that saves floor space and eliminates the need for a trench. The pumps allow efficient operation over the entire vacuum range without the need to change the pump's internals. When equipped with a center shroud, split vacuum operation up to 12 in. Hg (400 millibar) differential can be achieved. Large inspection ports allow easy access to pump internals for inspection and maintenance. For more aggressive applications, stainless steel, stainless steel clad and epoxy coated components are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 100 to 28000 m³/h; Vacuum to 33 mbar abs.; Discharge pressure to 3.5 bar abs. The 2BE1 series of liquid ring vacuum pumps and compressors is one of the most successful liquid ring pumps worldwide. A great number of models are available. The 2BE1 covers a broad range of suction volume, vacuum and discharge pressure. The series is certified according to ATEX and proved itself in many challenging applications. Vacuum pumps and compressors of the 2BE1 series are used in almost all industrial applications.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Available in both cast iron and stainless steel construction, the 2AV2 family provides up the 600 m³/hr (360 CFM) in a compact design, while giving you the flexibility of choosing the right motor for your needs. The pedestal design of the 2AV2 provides the benefit of flange mounting the motor to a self-supporting pump. No coupling guards, base plates or cumbersome shaft alignment is needed. The 2AV2 is an ideal choice when you need a compact and economical pump for an explosion proof or severe duty application. We focused on durability and dependability when we developed these liquid-ring pumps. With a reinforced stainless steel shaft and sealed bearings, the 2AV2 can provide up to 20,000 hours of maintenance-free operation. The 2AV2 is expertly designed and manufactured to be quiet and vibration free. With sound pressure levels of less that 75 dBA, it complies with the strictest noise standards, eliminating the need for additional sound attenuating devices. Advantages at a glance Compact Rugged design for reliable operation and long service life Precision-balanced rotor Suitable for NEMA C flange motor frames Low installation costs Easy to service Standard mechanical seal Main Applications Plastics Industry Chemical Industry Medical Technology Food and Beverage Industry General Industry

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

High Capacity Monoblock Pumps Available in cast iron construction, the 2AV1 family provides capacities up to 600 m 3/h (360 CFM) in a compact monoblock design. When compared to conventional pumps, the 2AV1's monoblock design delivers the benefits of a simple, compact and economical installation. Since the pump and motor are integral and self supporting, there is no need for additional baseplates, couplings or guards, which add to the cost, complexity and overall size of the installation. We focused on durability and dependability when we developed these liquid-ring pumps. With a reinforced stainless steel shaft and sealed bearings, the 2AV1 can provide up to 20,000 hours of maintenance-free operation. The 2AV1 is expertly designed and manufactured to be quiet and vibration free. With sound pressure levels of less than 75 dBA, it complies with the strictest noise standards, eliminating the need for additional sound attenuating devices. Advantages at a glance Compact Rugged design for reliable operation and long service life Precision-balanced rotor 60hz Motors, UL recognized components Available from stock Low installation costs Easy to service Standard mechanical seal Reinforced stainless-steel shaft in the pump body Main Applications Plastics industry Chemical industry Medical technology Food and beverage industry General industry

Request for a quoteResults for

Compressors - Import exportNumber of results

31 ProductsCountries

Company type