- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine tools for metal punching

Results for

Machine tools for metal punching - Import export

MICRON AMERICA

Turkey

It has been designed and constructed with respect to the pre punch holes to prepare a connecting element assembly, especially for metal plates. These packages are produced in order to order and delivery for approximately 3 4 weeks.

Request for a quote

EMSIL TECHTRANS SRL

Romania

Retrofit your machines to enjoy the modern age

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

The CNC milling machine for all upcoming tasks. Fast, precise and inexpensive. Including CNC control and 2D and 3D CAD/CAM ConstruCAM-3D software. Free lifelong LIVE Support ! CE-compliant commission only with protective housing and the suction socket.

Request for a quote

GRAVOTECH

France

VIN ENGRAVING MACHINE The Vehicle Identification Number (VIN) marking on chassis requires a reliable scribing machine, able to perform deep marking on all materials, from soft, such as aluminum to the hardest steels at a high speed. Our SV530 scribing marking machine has been used for more than 10 years with automotive products, proving fantastic durability and strength. SILENT MARKING SYSTEM Scribing technology performs silent marking on hollow metal parts (tubes and pipes) or formed plates (chassis and body parts) when these objects will naturally resonate during rotary marking. DIRECT PART MARKING Designed to combine depth with high speed and aesthetic results, our scribe marking machine has one of the best-marking speed/depth ratios: mark 17 characters of 7mm high. Powerful and fast, this machine creates deep marking before and after the treatment of parts.

Request for a quote

GRAVOTECH

France

OPEN STRUCTURE The M40 rotary engraver is 8.26x12in engraving area benefits from an open structure that allows larger items to be engraved when needed. Create custom engraving on very long plastic signage plates, electrical labels, thin wood beams, golf clubs, swords, irregular-shape items, and simply use as a sign engraver. GIFT ENGRAVING WITH THE M40 GIFT The M40 Gift includes an automatic lubricant tank and a rotary device to personalize glasses and bottles. The rotary device can be tilted for conical items. Engrave and personalize any flat or cylindrical items up to 4.33in height. BEGINNERS ROTARY ENGRAVER Control and adjust your work with our dedicated Gravostyle™ or ABC engraving software, thanks to several options. The M40 comes with an auto-centering jig and a laser beam (Point & Shoot) to help you place the item to engrave, while the engraving software automatically picks up its position. The included Gravogrip™ table firmly holds the item without leftover residue on it.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

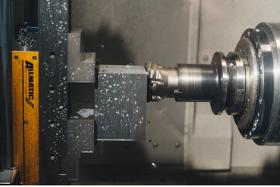

Description: •Precision machined components, Machining service, CNC precision machining, Stainless steel precision machined parts manufacturer •Material to process: aluminum, stainless steel, carbon steel, brass •Precision: 0.010-0.002mm •Equipments: CNC lathe, processing center, miller, cylindrical bore grinder, surface form grinder, punching machine, etc. •Surface treatment: zinc, nickel, anodized, polishing •Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. •We are able to supply Precision machined components, mechanical parts machining, surface treatment such as anodize and plating according to our customers’ requirement. •Packaging details: inner plastic bag, outer standard carton box •Delivery time: 25-35 days Notes: we manufacture precision machined components in compliance with customer’s designs. The products are shown here ony to present the

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

High precision steel shaft/splined shaft for connecting/coupling shafts 1) Customer’s drawing or samples accepted. 2) Excellent and high quality control. 3) Prompt delivery. 4) Competitive price. steel shafts 1) Material: Carbon steel , Stainless steel,brass or as per customer’s requirements. 2) Diameter: 0.3-80mm, tolerance:+/-0.005mm. 3) Roundness: 0.003mm. 4) Roughness: Ra0.04. 5) Straightness: 0.005mm. 6) Hardness: HRC/HV. 7) Precision: Grade 6. 8) Length: Max.700mm. 9) Heat treatment:Point hardening,quenching hardening. 10) Surface treatment: zinc plating, nigrescence,chrome plating, nickel plating etc. 11) OEM Service: Providing us the drawing with detail information. 12) Offering products with speciality, quality and efficiency. 13)Package:Plastic bag inside and outer standard carton , pallet.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Machining Parts ● Materials for CNC Precision machining parts We can process product materials are: An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from1050-7475), commonly used are: 2011,5052,6061,7075, etc. (2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000 (3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades(JIS grade corresponds to the basic, together with the SUS can):201,301,303,304,314,316,420,430,630 Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15) ● CNC Precision machining parts accuracy Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm ● Maximum size of Precision parts suit to CNC machining

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Metal Shaft Motor shaft, Fan shaft, Precision shaft, Micro Shaft, Rotor shaft, Pump shaft, Pins, Hinge pin, Metal part, Mechanical precision part. Mechanical precision part/Mechanical precision part. 1) Material: Carbon steel, Stainless steel, brass or as per customer’s requirements. 2) Roundness: 0.001mm 3) Roughness: Ra0.04 4) Straightness: 0.001mm 5) Length: Max. 1000mm 6) Heat treatment: Point hardening, quenching hardening 7) Surface treatment: Zinc plating, nigrescence, chrome plating, nickel plating etc. 8) OEM Service: Providing us the drawing with detail information. 9) Offering products with speciality, quality and efficiency. 10) Package: Plastic bag inside and outer standard carton, pallet. According to client’s demand. Specifications for CNC METAL SHAFT

Request for a quote

INGENIERIA IRADI S.L.

Spain

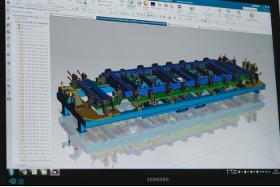

Our team of engineers thoroughly researches each project and designs the most appropriate solution for each customer. The technical office works in accordance with the needs of the customer or independently to meet a stated requirement. We offer complete solutions from design, manufacturing and quality control to on-site commissioning. We have a flexible structure, a dependable supplier network, technical training, and in-depth project knowledge. Our highly qualified technical department works with advanced 3D design programmes and we optimise our designs by means of finite element calculations, eliminating uncertainties and ensuring the correct functioning of each application.

Request for a quote

INGENIERIA IRADI S.L.

Spain

Ingeniería Iradi also designs, develops and manufactures equipment and special machines as well as conducting engineering studies and implementing automation proposals for repetitive manufacturing processes. We design the necessary equipment to facilitate the manufacturing, handling and assembly process We design and manufacture different types of equipment: - for the welding process - for verification and control - for holding - for turning - for detection - for assembly and calibration We have qualified personnel with extensive experience in the assembly and integration of various components and subsystems, and we collaborate closely with entities that specialize in electrical and electronic systems.

Request for a quote

INGENIERIA IRADI S.L.

Spain

Machining according to drawing, from prototypes and unit batches to small and medium-sized production runs We specialize in serial production and machining of all components that require machining on lathes, milling machines, and machining centres.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Each our component is individually handled in complete care and tested with the latest measuring devices - Mitutoyo. Specialized in smaller productions has its own advantages. We individually devote ourselves to our partners. We support you by: - before production, we review the technical documentation and implement possible changes, - we have a larger amount of material in stock which guarantees us an immediate start of production and quick delivery of a new spare part, - all products are inspected, deburred and hand polished before release. The components are checked to ensure that they fit properly and that the external product is compatible. All dispatched products are functional and visually sophisticated. Which leads to more affordable and better quality of the end-product, and consequently greater satisfaction of our partners.

Request for a quote

MVD MACHINERY

Turkey

MVD Turret Punch presses are produced as a closed type rigid steel constructions in to a robust structure to provide minimum deflection during operation. Complete solutions with effective costs.

Request for a quote

FOXLASER

Bulgaria

The punching is a preferred technology in cutting-out of galvanized metal sheets. In FoxLaser we have 4 pc. punching machines that enable us to process without repositioning sheet material with dimensions 3000/1500/3mm. The main advantage compared to laser technology is the possibility of cutting and forming of the sheet material. The combination usage of punching and laser cutting allows us to make numerous identical holes (grid) or just forming in a laser cut parts. The biggest advantage in FoxLaser punching are a tripple tooling we have that allows us to produce same time same part in all machines. For achieving maximum performance we work with wide range of functionalities by the well proved softwares SigmaNEST and Metalix CNCKad, in combination with the customized software of the company AMADA.

Request for a quote

HTMACH - HT GRUP MAKINA A.S.

Turkey

HTMACH Turret Punch Press Machine is capable of working large sheet metals with fast axes speed and stroke frequency. It is used high level mechanic and electronic automation equipments in its construction. Machine keeps its compact structure with all its specialties and equipment. All of the components on the machine are world wide known brand names. Capacity is 1225mmX30ton

NITTO KOHKI EUROPE GMBH

Germany

New design adopted for punching stainless steel. Inching function as standard. 25mm and 26mm dia. holes are possible with optional parts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOGRAMA AG

Switzerland

The BSM 750 Servo with integrated front trim lends the booklet its final form. Front trim, head and foot trim, and blank separation are performed in one operation.

Request for a quote

BOGRAMA AG

Switzerland

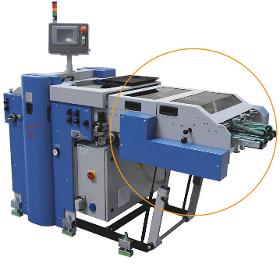

"The compact and attractively priced BSR 550 basic is structured as an offline solution. It is designed specifically for users who want to produce small and medium runs economically and efficiently as well as for those for which the flexible connection options and technical features of the BSR 550 Servo have no priority. Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. To exchange the flexible dies the entire breakout and deliver unit is disconnected from the die-cutting area. Thus an optimal accessibility is guaranteed. After die-cutting the inner cuts are separated and the section grids deflected.

Request for a quote

BOGRAMA AG

Switzerland

This machine configuration is the most flexible variant. It can not only be combined with downstream but also with upstream equipment such as cross cutters, digital printing machines and folding machines. Products are fed individually to the punching area via register table and rotary punched by using a flexible die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h.

Request for a quote

BOGRAMA AG

Switzerland

In this configuration variant, products are fed to the punching area individually from the pallet feeder and rotary punched by using a flexible die. The maximum stack height of the feeder is 100 cm. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed.

Request for a quote

BOGRAMA AG

Switzerland

Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h

Request for a quote

BOGRAMA AG

Switzerland

Where punch force is crucial. Fitted with a high-performance servo drive, capacity rises to 12,500 cycles/h. High punch force for die-cutting (to max. 4 mm) High-performance 5kW servo motor Controllable cutting speed Available in two working widths.

Request for a quote

PRECITOOLS SRLS

Italy

We present semi-automatic grinding machine F-Grinder to sharp punching tools (punches and dies) for various models and systems of punching presses: Trumpf Trumatic, Trumpf Trupunch, Boschert, Haco, Pullmax , Amada, Finn-Power, Prima-Power, Durma, Schiavi, LVD, Strippit, Danobat, Yawei, Nisshinbo, Euromac, Baykal, FIM, Murata Muratec, Rainer, MVD, Tailift, SimasV, Yangli, Peliant, SNK, Pullmax, Hesse-Maschinen, Ermaksan, Dener, ITEK, SMD etc. Grinding of punches and dies with height up to 230 mm, diameter of 180 mm. Control panel SIEMENS TOUCH. Machine is with coolant, closed grinding area, 3-jaw universal chuck, no any additional adapters are needed. Table tilt to make the angle grinding. Please contact by E-mail for the detailed offer. This is the advertisement, not the official offer. All the mentioned brands and trademarks pointed just for the information and are the property of their respective owners.

Request for a quote

EZSO, LLC

Russia

With our equipment you can make flight screws (feathers) up to 50 mm thick of any geometry and from any steel grade. The equipment is fitted with modern CNC control and software, which allows you to maintain accurate repeatability and ideal geometry of the flight screws. SPECIFICATIONS Overall dimensions of the press, L/W/H - 3200 mm / 1350 mm / 1500 mm Overall dimensions of the control unit, L/W/H - 1000 mm / 800 mm / 1650 mm Unit weight ready-assembled - less than or equal to 8000 kg Working pressure in the hydraulic system - 21 MPa Maximum pressure in the hydraulic system - 25 MPa Nominal press power - 100 tons Maximum short-term power - 110 tons Mains voltage - 380 V Power consumption - 22 kW Outer diameter of the coil - not limited Maximum flange height - 680 mm Maximum flange thickness - 2 mm - 50 mm Maximum flange pitch (with standard equipment) - unlimited

Request for a quote

OSMAK RULO MAKINA SAN. VE LTD.STI

Turkey

Defense industry is one of the most important element for every single nation. We are proud to serve Turkish defense industry with costum design machining parts. Osmak is your reliable solution partner of many type of custom design machining parts. Please do not hesitate to contact us to place your order.

Request for a quote

BOGRAMA AG

Switzerland

High-performance drum feeder with low feed height for comfortable working. With a capacity of up to 20,000 cycles/h, the TA 20 is also deployed for the small folds of rotary printing sheets.

Request for a quote

BOGRAMA AG

Switzerland

Mobile transfer table for inline configuration of BSR 550 Servo with machines interfaced upstream such as cross cutters and digital printing machines.

Request for a quote

BOGRAMA AG

Switzerland

Simple, cost-effective delivery with fixed height.

Request for a quoteResults for

Machine tools for metal punching - Import exportNumber of results

34 ProductsCountries

Category

- Machine tools - metal machining (16)

- Cutting - machine tools (12)

- Punching machine tools (12)

- Machine tools, metal machining - parts and accessories (8)

- Metal engraving - machine tools (3)

- Bending machine tools (1)

- Folding machine tools (1)

- Grinding - machine tools (1)

- Machine tools, metal shaping - parts and accessories (1)

- Metallurgy - machinery and installations (1)

- Steels and metals - machining (1)