- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision balls

Results for

Precision balls - Import export

PEEKCHINA CO., LTD.

China

Manufacturing Process CNC Machining & Injection Molding PEEK performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% glass fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Based on our many years of experience in developing and manufacturing high-quality machine components, GMN has specialized in the area of high-precision ball bearings as well as the production of high-performance and long-lived deep groove and spindle ball bearings to meet – or even exceed – the highest precision classes P4 and ABEC 7. Certification under international standards ensures the highest precision in the development and manufacturing of GMN ball bearings and guarantees constant, outstanding qualities related to speed suitability, stability and longevity. The broad product range includes a large selection of standard solutions as well as requirements-tailored special designs.

Request for a quote

MPS MICRO PRECISION SYSTEMS AG

Switzerland

MPS Microsystems offers a complete range of high precision ball screws for positioning less than 5 µm. Mostly custom-made, these screws ensure smooth and uniform movement resulting from the high precision of their thread, achieved by grinding. Our ball screws are made exclusively of stainless steel and are fitted with double nuts to allow fine adjustment of the axial play. Moreover, an optional ogival thread can provide a higher static and dynamic load capacity. Thanks to a large number of options, we can ensure that the ball screw meets your technical and quality needs. The following parameters can be personalized: lubricant (grease, oil, dry lubrication, no lubrication), customized screw ends, shape and external dimensions of the nut and screw, multiple nuts on the same screw, left-hand thread, thread length, specific axial play, special surface treatment, and more.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Balls are widely used on bearings with extreme performance requirements, such as: High-speed bearings, high precision bearings, vacuum bearing, high / low-temperature bearing, non-magnetic bearing, high precision ball screw; it is also used as valve ball, measuring ball for the chemical pump, heat pumps, metering pumps. Its excellent properties including: Good corrosion resistance withstands attacks from harsh chemicals and environments. High-Temperature Hardness is twice that of steel, Silicon nitride ceramic balls retain their strength and hardness up to 1800 degrees F.Lightweight, silicon nitride ceramic balls’ density is 3.20g/cm3 and weighs 45% less than steel which reduces centrifugal force, skidding and wear under high speed and acceleration, so greatly extending the service life. Superior Surface Finish is conducive to improving working speed and reach higher accuracy.

Request for a quote

ROLLON GMBH

Germany

MONO RAIL is a profiled linear rail for high precision under heavy loads. Four rows of balls run in the self-lubricated slider. The running surfaces of the sliders and rails are hardened and polished. Sizes from 15mm to 55mm Standard and flat sliders, with and without flanges Different precision and preload classes Fixing holes from the bottom are available Comprehensive range of accessories, e.g. metal wipers or cover strips MINIATURE MONO RAIL models are mini linear guides with 7mm, 9mm, 12mm and 15mm widths, for particularly noiseless operations. Robust: corrosion and dust resistant Quiet running due to the unique ball channel’s geometric configuration Four-point contacts for equal load capacity in all directions Sliders can be separated from rails without losing balls Long maintenance intervals due to sealed lubrication cycle The MONO RAIL linear guides product family includes profiled linear rails to ensure the highest precision for heavy loads. The availability of sliders...

Request for a quote

ROLLON GMBH

Germany

Compact Rail is a linear system consisting of steel linear rails with induction hardened raceways and high precision radial ball bearing sliders, also made of hardened steel. Thanks to their self-aligning capabilities, Compact Rail linear guides simplify the project, improve the performance and reduce the overall cost of application. Compact Rail linear guides are easy to install on all types of surfaces, including non-machined ones. Compact Rail linear guides feature a robust steel slider with ball bearings, self-centering heads with wipers, longitudinal seals to protect the internal components and a top sealing strip. The slider body is accurately finished with matte longitudinal edge chamfer and a shining ground flat surface. The slider heads are equipped with special slow release felt pads and are free to rotate with respect to the slider body, so that the felts are always in contact with the raceways to ensure optimal lubrication.

Request for a quote

SCHOCK GROUP

Germany

Cold-drawn heavy-duty rails offer exceptionally high load-bearing capacity and stiffness. In our eShop, you can find partial extensions, full extensions, and over-extensions up to 3000 mm in length and with a load capacity of up to 2400 kg. Cold-drawn heavy-duty telescopic extension rails are suitable for extreme loads and stresses. The precision-machined ball tracks ensure accuracy and provide excellent shock and vibration resistance. Therefore, these telescopic rail models are well-suited for demanding tasks in machinery manufacturing, the military sector, special vehicle construction, and heavy-duty shelving. Due to their extreme strength, these telescopic rails are particularly resistant to lateral forces, making them an excellent choice for dynamic and motorized applications, especially at very large lengths. They can also be used at high temperatures since no plastic parts are used.

Request for a quote

ROLLON GMBH

Germany

The PRECISION SYSTEM series of linear units are self-sustaining profile systems made of extruded aluminum and steel for the TK series, able to ensure excellent precision. The motion is achieved by means of precision rolled recirculating ball screws with preloaded or non preloaded ball nuts, depending on the models. Using the recirculating ball bearing technology for the screws and the rails ensures great performance to the linear actuators, such as: High precision and high axial forces High mechanical performance Low wear and tear Low resistance to movement High speed (for long pitch screws) The Precision System series consists of 4 distinct products with different features: TH, TT, TV, TK. PRECISION SYSTEM - TH TH linear actuators are rigid and compact, ball screw driven linear units, enabling high positioning accuracy and repeatability in all process phases with optimal performance assured, with a repeatability within 5 µm. Thrust force transmission is achieved by means of...

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Precision Positioning Table TS/CT is a compact positioning table made of a cast iron slide table and bed with high rigidity and vibration damping performance, incorporating an IKO Crossed Roller Way with a solid record in the field of precision linear motion rolling guides, and using a precision ball screw for the feeding mechanism. IKO Precision Positioning Table TS/CT is available in oneaxis and twoaxis specifications and is widely used in precision measuring instruments and precision assemblers that require high precision positioning.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Micro Precision Positioning Table TM is an extremely compact precision positioning table incorporating a precision grinding ball screw with a thread diameter of 2 mm and an IKO Micro Linear Way L with a track rail width of 2 mm, wellestablished in the field of ultrasmall equipment.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Precision Positioning Table LH is a highreliability, highprecision and highrigidity positioning table made of a cast iron slide table and bed with high rigidity and excellent vibration damping performance, incorporating an IKO Linear Way and using a precision ball screw for the feeding mechanism. By incorporating two Linear Ways in parallel, it achieves stable running accuracy, high positioning accuracy and large carrying mass. It is available in four sizes ranging from 120 mm to superlarge 420 mm in table width, and tables combining these in a twoaxis specification have also been serialized. It is optimum as a highprecision positioning mechanism for usage where the applied load is large and the stroke length relatively long.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Our uncoated Precision Ball Lenses can be achieve a very high level of yield of magnification & are widely used for focusing & coupling light into and out of Microscopes. We can offer these in Sapphire, made from Al2O3, and BK7 or equivalent material. Sapphire allows for superior optical transmission qualities The key feature of ball lenses is their short back focal length allowing for precision coupling where size or space is a limiting factor in the system & therefore ideal in the use of Microscopes or microscopic attachments onto devices such as mobile phones. Ball Lenses are manufactured from a single substrate of glad and therefore, depending on the geometry of the input source, can focus or collimate light. Half Ball Lenses can also be used as an interchange with a full ball lens for more compact designs. Read the PDF for more information....

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Alignment Table AT is a rotary positioning mechanism capable of precise angle correction, in which a high rigidity steel table and bed are used and IKO Crossed Roller Bearings are incorporated in the bearings supporting the table. Alignment Table AT uses the ball screw drive to convert linear motion into circular motion in a fixed angle range and positions the table in the rotational direction. An IKO Linear Way L is used for the linear motion rolling guide of the ball screw drive mechanism, combined with a precision ball screw to achieve high precision positioning. Placing Alignment Table AT on the slide table of the IKO Precision Positioning Table enables the configuration of a low height XYθ multiaxis positioning mechanism. This enables the table to be used as an alignment table for precision measuring equipment, inspection equipment and assemblers.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Precision Positioning Table LH is a highreliability, highprecision and highrigidity positioning table made of a cast iron slide table and bed with high rigidity and excellent vibration damping performance, incorporating an IKO Linear Way and using a precision ball screw for the feeding mechanism. By incorporating two Linear Ways in parallel, it achieves stable running accuracy, high positioning accuracy and large carrying mass. It is available in four sizes ranging from 120 mm to superlarge 420 mm in table width, and tables combining these in a twoaxis specification have also been serialized. It is optimum as a highprecision positioning mechanism for usage where the applied load is large and the stroke length relatively long.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Precision Positioning Table L is a lightweight, long stroke positioning table configured with the slide table and bed made from highstrength aluminum alloy. High accuracy and carrying mass are realized by incorporating two sets of IKO Linear Ways in parallel, and using a precision ball screw in the feeding mechanism. Maintenance work such as relubricating with grease can be reduced significantly by CLube. Various table sizes and stroke lengths are available, and dedicated XY brackets are also serialized, enabling systems such as orthogonal robots to be easily configured according to the application. Precision Positioning Table L is ideal as a highprecision positioning mechanism, for assemblers, processing machines, or measuring instruments.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Precision Positioning Table TE is a lightweight and compact positioning table using highstrength aluminum alloy for its main components, with a slide table assembled inside a Ushaped bed. A precision ball screw is used for the feeding mechanism, enabling highreliability and highprecision positioning. Lubrication part CLube is built into the linear motion rolling guide and ball screw, achieving long term maintenance free performance and reducing lubrication work. Various specifications such as ball screw lead, motor type and sensor mounting can be configured, enabling the optimum positioning table to be configured according to the application. Ideal for a wide range of applications ranging from equipment that requires high positioning accuracy such as parts machining, assembly, inspection and conveying equipment through general conveying fields.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

The IKO Precision Ball Slide is an extremely compact and lightweight linear motion rolling guide with the track portion and mounting surface integrated, made into a rolling guide by precisely molding a stainless steel plate into a U shape. Since high performance and quality can be stably maintained for a long period of time, it is widely used as a precision linear motion rolling guide for the magnetic head guiding parts of precision measurement instruments and computer external storage devices, and also as a functional part for precision linear motion such as for semiconductor manufacturing and testing and inspection equipment. Models are available in abundant performances and sizes, and can be selected according to the application. Stainless steel highly resistant to corrosion is used for all steel components, so that they are suitable for applications in a cleanroom environment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN offers a complete range of sizes, types and designs with its spindle ball bearings in standard sizes S, SM and KH. In conventionally oil-lubricated spindle bearings, lubricant is supplied through a lateral oil supply. GMN spindle bearing designs +A, +AB, +L and +LB provide direct oil supplies to the lubrication point through a bore in the outer ring. GMN spindle bearing designs +AG ensure the highest possible machine running times without complex oil supply systems. These feed the lubricant directly into the lubricating point through holes in the outer ring. The developed high-performance, separable BNT and BHT designs ensure fast and uncomplicated handling, especially with regard to assembly and maintenance.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

The use of high-precision radial groove ball bearings is especially recommended when axial forces are supported in two directions, but the installation space makes the use of a spindle bearing pair impossible; plus when the best-possible guide for rotating components is needed, but the RPM requirements are less important. Depending upon the load capability and the installation space available, GMN provides deep groove ball bearings in sizes 60 and 62 as per DIN 625. A large selection of various cages, lubricants and covers make it possible to adapt GMN deep groove ball bearings to any application.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Material Schulz Stanztechnik manufacturers these axial ball bearings using the materials suited to the specific application. For the housing, steel, brass or stainless steel are used; for rings, steel or stainless steel which is always hardened. The balls are made of chrome or stainless steel, which is also always hardened. All material combinations – depending on their conditions of use – are possible for the assembly of the individual parts. Various surface coats for the individual parts can be supplied as well as finished bearings: brass which is uncoated or nickel plated; steel and stainless steel which is uncoated, zinc plated or nickel plated. All bearings are available lubricated or unlubricated. Structure DLG100 axial ball bearings consist of sheet metal housing, two hardened rings as well as hardened precision balls. Due to their structure, we refer to them as an encapsulated, full ball design.

Request for a quote

NORELEM FRANCE

France

Material: Housing thick steel plate. Tyres steel-wire reinforced elastic solid rubber. Wheel body welded steel. Version: Housing press formed. Reinforced fork, base plate and centre pin. Double ball bearing with hardened shells in the castor head. Precision ball bearings in the wheels. Note: These castors are particularly impact and shock proof and assure a high service life. Wheel axle bolted.

Request for a quote

NORELEM FRANCE

France

Body carbon steel. Balls roller bearing steel. Diverters plastic. Standard guide carriage with recirculating ball guidance precision N not preloaded (Z0). With doublesided end seal. 4row versions with round arch profile. The profile guide rail tracks are arranged at 45° and can accept loads from all directions. High dynamic values v = 5 m/s. Applicable temperature in continuous use max. 80 °C. On request Various precision and preload classes. Drawing reference 1) ground ref. edge

Request for a quote

NORELEM FRANCE

France

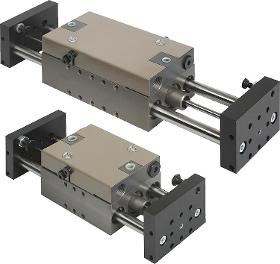

Body and flange plate EN AW5754. Guide shafts steel Version Body, hardcoated Flange plates, anodised. Guide shaft, hardened. Note Maintenancefree pneumatic linear modules with two precision steel shafts and ball guide bushing with wipers. Double acting cylinder drive. All fastening threads have threaded inserts. The as accessory available shock absorbers and proximity switches can be integrated (no protruding edges). Positive fit construction for hundred per cent reproducibility. Combinations in all sizes and stroke variants are feasible without adapter plates. Repeat accuracies of ±0.01 mm are possible. Specified loads apply by centred carriages. On request Available with locking cartridge as stroke deviation safeguard. Accessory See table for shock absorber, proximitiy switch and plug connector.

Request for a quote

PRESSTA EISELE GMBH

Germany

4 axis CNC floor-type vertical spindle machining center. 4 axis (X, Y, Z, A) managed by CNC. By means of dedicated tools it’s suitable for working on 5 sides of aluminium, PVC and steel sections. The work pieces are held by means of 4 pneumatic vices on the mobile beam, that can be positioned on any angle between +125° and -125°. The rotation is directly managed by the control cycle. It offers a high programming functional capacity by using a three-dimensional graphics software. Electro-welded base designed to grant maximum rigidity and functional capacity of use. The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The vices slide on ball recirculation screws, and can be positioned manually by referring to a mm-scale and a laser pointer. By using the disc cutter it is possible to carry out end-milling operations on both the ends of the work piece (end-milling cycle). Milling operations can be performed with...

Request for a quote

PRESSTA EISELE GMBH

Germany

4 axis CNC floor type vertical spindle machining centre. 4 axis (X, Y, Z, A) managed by CNC. By means of dedicated tools it’s suitable for working on 5 sides of profiles. Suitable for processing on ANY surfaces, generated by the rotation of the spindle axis (side by side at Y axes) on the positions within 180° (± 90°). The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The locking clamps slide on guide rail. The working table can be divided in two areas so to get two separate working stations. Using a disk cutter, it is possible to work on both sides at the end of the profile (end milling cycle). Milling operations can be performed with linear and circular interpolation of the axes X-Y-Z. The hinging length stop are pneumatically managed. The electric spindle is suitable for quick tool holder change. The tool magazine is mounted on the mobil upright. The tool change can be carried out into any position...

Request for a quote

PRESSTA EISELE GMBH

Germany

5 axis CNC floor type vertical spindle machining center. 5 axis (X, Y, Z, C, A) managed by CNC. Suitable for milling, drilling, tapping and cutting on the 5 sides of aluminum, PVC, steel and light alloys profiles; thanks to the 5 axis interpolation, the machine is able to execute composite cuts. The X or longitudinal axis, the Y or transversal axis and the Z or vertical axis belong to the tool movement. They can be interpolated in linear and circular way on 3-dimension geometrical planes, belonging to X-Y-Z. The C axis can be turned and positioned on all angles within 440° (± 220°); the A axis can be tilted and positioned on all angles within 250° (± 125°). The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The locking clamps slide on guide rail. By using the disc cutter it is possible to carry out end-milling operations on both the ends of the work piece (end-milling cycle). Milling operations can be...

Request for a quote

GRAVOTECH

France

HIGH-PERFORMANCE With automatic density adjustment to maximize marking speed and readability, automatic part detection and multi-level marking the XF510m performs at its best constantly. Fitted with multi-dot technology making it possible to carry out deeper markings, it becomes your go-to solution for direct part marking. RELIABLE & DURABLE Utilizing high precision zero-play ball screws, high rigidity guide rails, and integrated cooling the XF510m is designed to be bold and run problem-free in the most demanding of environments. DOT PEEN MARKER Mark any type of 2D code, Data Matrix, QR code engraving, UID, GS1, Unicode characters safe in the knowledge that our ultra-precise M1L stylus will be providing unparalleled accuracy. Also use for aluminum plate engraving, steel engraving, VIN plate engraving, and as your favorite metal marking machine.

Request for a quote

MPS MICRO PRECISION SYSTEMS AG

Switzerland

MPS Microsystems is specialized in manufacturing high-precision, miniature linear bearings. We offer a comprehensive range of exceptionally smooth bearings with bore diameters from Ø 2 mm to Ø 6 mm. The balls of these precision bearings meet ‘Grade 3’, the highest quality defined by the ISO 3290/DIN 5401 standard. Combined with a cage and a high precision casing, they allow rapid positioning while reducing friction and eliminating the stick-slip effect. The standard version of MPS Microsystems linear bearings consists of a stainless steel bushing and balls, and a brass cage. An all-stainless steel version or one with ceramic balls can be made on request.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our KIS hybrid bearings combine the best of two worlds - the robustness of classic rolling bearings (or stainless steel bearings) and the efficiency of state-of-the-art materials. With an optimised combination of high-quality steel rings and precise ceramic balls, our hybrid bearings offer outstanding strength and durability. Rolling elements made of ceramic offer a current-insulating property. These hybrid bearings have the same dimensions as comparable all-steel bearings and can significantly improve the reliability and robustness of machinery and equipment. In particular, they show their advantages in applications where the bearings are confronted with contamination from abrasive particles, insufficient lubrication, vibrations or current passage. At KIS, we optimise our materials for hybrid bearings to ensure flawless performance in applications under critical conditions at all times.

Request for a quoteResults for

Precision balls - Import exportNumber of results

52 ProductsCountries

Company type

Category

- Bearings, ball (9)

- Mechanical transmission - components (8)

- Bearings - ball, needle and roller (3)

- Internal transport systems (3)

- Ceramics, industrial (2)

- Potentiometers (2)

- Testing equipment (2)

- Wheels, castors and rollers - metal (2)

- Precision balls (1)

- Autogenous welding machines (1)

- Bearings, roller (1)

- Energy - renewable (1)

- Expansion joints - ferrous metal (1)

- Industrial robots (1)

- Marking machines (1)

- Measurement - Equipment & Instruments (1)

- Optical instruments (1)

- Rails and sliding frames (1)

- Surgical apparatus and equipment (1)

- Universal joints (1)