- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pellet feeds

Results for

Pellet feeds - Import export

ROBINSON CO.

Turkey

Pellet sieves, take the oath pelletized powder pellet press again sends to the upper reservoir. pellet separated from the dust, Sent to the finished product silos. Depending on the space 2 or 3 cassette and 2 or 3 It is produced as output. Manufacturing is done in two separate models; vibrating screen and rotary screen. the centrifugal force will occur due to vibration and shaking vibration body vibration minimizing the special chassis system for dust separation, characterized in pellet diameter kullanılmaktadır.h. Dust sealing özelliği.kolay be changed 2 or 3 There ply sieve tray system. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quote

ROBINSON CO.

Turkey

Pellet mill’s working principle is, mash feed is forced outward through holes in a ring die by the action of two or three rollers, which is then cut to a predetermined size. Before mechanical process, steam can be injected into the conditioner at temperature 85 degrees celsius. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

The pellet crusher is a crusher specially designed to break 03-5mm granules into small pieces. With this design, the quality of pellet feed and pellet feed is improved. It is mainly used for poultry and fattening pellets and aquaculture pellets. The pellet crusher has two rollers, the working distance of which can be adjusted (manually or by motor). Thanks to the specially designed abilene rollers, all kinds of grains are processed with high capacity and quality. These rollers can always be used correctly to ensure high efficiency. The roller mechanism is fed regularly by the power supply unit. The pellet is evenly distributed over the entire surface of the roller. Thanks to a regular feeding with this mechanism, a homogeneous structured feeding with a low power and a lower dust content is obtained without overloading the machine. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quote

ROBINSON CO.

Turkey

The control sieve is used for the final control before packaging in the packaging unit of the flour factories. The product arriving at each passage of the square screen enters through the pressure pipe and moves vertically and horizontally through the pre-set flow paths along the passage. The final checks are made after the flour sifting process. The flour, whose last checks are made, is directed to the bagging process. Apart from flour and semolina factories, it is used in processing plants of wheat, corn and similar grains, in feed mills, in various food products processing plants for the final screening of mixed feeds and for the sifting of large-grain corn, crushed pellet feed, barley, oats and similar processes. Application Fields ◾ At flour mills: For wheat, corn and similar grain processing plants ◾ At feed mills: For final sifting of formulated feed meals, corn, crushed pellet feed, barley, oats and for removing the remained coarse materials after grinding and similar processe

Request for a quote

STATEC BINDER GMBH

Austria

The ACROPAC is a fully automatic bagging machine with a production capacity of up to 600 bags per hour. Hence, this open-mouth bagging machine is ideal for those who want to change from manual/semi-automatic packaging to fully automatic packaging and/or require low capacity. Whether plastic pellets, animal feed, fertilizer or food, the ACROPAC is ideal for packaging free-flowing bulk materials. Due to the high flexibility of the machines, pillow bags and gusset bags with a filling weight between 10 kg and 50 kg can be filled. The bags can be made of woven PP, PE or paper. In order to meet special requirements, the machine is also available in a stainless steel execution and can be equipped for powdery products.

Request for a quote

GEBR. DÜRRBECK KUNSTSTOFFE GMBH

Germany

FFS film is an interesting alternative to ready-made plastic bags. Form fill seal film is perfect for packaging granulate, powder, grain, feed, wood pellets and more in one quick and easy step. FFS film manufactured by Dürrbeck meets the highest standards, guaranteeing the perfect protection against dust, moisture and other harmful elements. FFS film bags are easy to fill thanks to the power of gravity, and fulfil a variety of demands thanks to the many available options – including, for example, perforation or ventilation to allow moisture or air to escape from the bag, or a higher coefficient of friction (COF) that improves the stability of the load during transport.

Request for a quote

AJ AGRO APS

Denmark

We are putting forward a stock of Cattle Feed Pellet that is demanded all over the world in livestock industry. This is a kind Biomass Pellets processed under the most hygienic climates with approved methodology. The offered feed is loaded with multiple nutrients vitamin A, B, C & E, proteins, dietary fiber, carbohydrate, so on. As a result, it is useful in enhancing immunity, and growth of cattle, and preventing them for varied diseases. Highly effective and safe to consume, the Cattle Feed Pellet is kept up in A-class packaging and at moderate prices.

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Small-size twin screw feeder for powders or rotary tube feeder for pellets and fine-grained media — Feed rates as low as a few grams per hour — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy Power range 1-5 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Small-size twin screw feeder for powders or rotary tube feeder for pellets and fine-grained media — Feed rates as low as a few grams per hour — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy Power range 1-5 dm³/h

Request for a quote

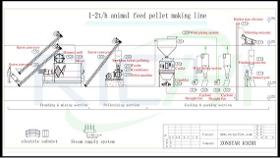

HENAN RICHI MACHINERY

United States

The feed pellet manufacturing line can process feed pellets for various animals, such as chickens, cattle, fish, pigs, rabbits and shrimps. Due to the pelleted feeds are nutritious, easy to digest and absorb, easy to store and transport, more and more farmers tend to make feed pellets for their animals. The main equipment in this manufacturing line are: animal feed pellet maker, feed crushing machine, feed mixing machine, feed cooling machine, feed packaging machine, etc. With 27 years of experience in in feed machinery manufacturing and development, RICHI Machinery can not only provides animal feed pellet production lines of various scale, but also can customized animal feed production business plan according every customers’ requirements. If you have any need in making feed pellets, welcome to contact RICHI, we will reply to you within one business day.

Request for a quote

HENAN RICHI MACHINERY

United States

RICHI shrimp feed pellet production line adopts unique design and advanced technology with three-layer conditioners, which is an ideal equipment for making shrimp feed pellets. Capacity: 0.3-15T/H Main power: 22-355KW

Request for a quote

HENAN RICHI MACHINERY

United States

Sawdust pellet mill is mainly composed of feeding system, pelletizing system, transmission system and overload protection system. After the machine is turned on, first put into the feeder according to the production demand, the material enters into the pelletizing chamber for pelletizing through the feeder, and is converted into wood pellets and extruded out of the die holes under the extrusion of the ring die and the pressure roller. The produced wood pellets have smooth surface, high density and high hardness, which can be mainly used for civil heating and living energy.

Request for a quote

PERLYNA STEPU LLC

Ukraine

This high-quality feed is enriched with vitamin pellets, which will provide your budgerigar with all the necessary vitamins and trace elements. Carefully selected ingredients will satisfy all the needs of the parrot and will become its favorite diet. Composition: yellow millet, flax, black millet, vitamin pellets, red millet, canary seed, safflower and etc.

Request for a quote

STAMIXCO AG

Switzerland

The SMN Injection Molding Static Mixing Nozzle creates homogeneous mixing of polymer melt during injection. The resulting high viscous polymer melt flow is homogeneous with regard to colorant, additives and temperature. Benefits Outstanding melt flow mixing of molten polymer prior to injection results in the following benefits: Reduced spots, streaks and clouds of color Reduced colorant usage (10% - 40) Narrower part tolerance Reduced reject rates Less part distortion Less weight variation Improved part quality when using regrind material Shorter cycle time Improved melt flow Increase regrind ratio with consistent product quality Rapid nozzle heat-up Normal Pay-back period of 2-3 months Filter for Injection Molding Static Mixing Nozzle (Type SMF) The optional SMF Filter is installed inside of the Static Mixing Nozzle to protect the hot runner system and mold when processing regrind materials by avoiding clogging and/or damage with debris carried along with the feed pellets. Grid Protection Disk for Mixing Elements (Type GPD) The optional GPD Grid Protection Disk is installed inside of the Static Mixing Nozzle upstream the first mixing element. During the start-up operation it avoids a possible so called “cold-start” damage of the mixing element grid by plugs of not completely molten and thus partly solid polymer plugs originating from the transition part between the end of the barrel and the Static Mixing Nozzle Benefits & Function The SMF Filter is designed to be used with the SMN Injection Molding Mixing Nozzle. The purpose and functionality of the SMF filter are numerous: Protects hot runner system and mold by avoiding clogging and/or damage caused my metal pieces accidentally introduced with the feed pellets to the injection molding machine (staples, metal chips, paper clips, etc). Retains semi-molten polymer pellets until melted for incorporation into the polymer melt For customers with poor thermal control systems, the SMF Filter acts as an upstream breaker-plate to prevent “cold-start” crushing of the mixing elements. Designed to retrofit into the SMN Injection Molding Mixing Nozzle without nozzle modification O.D. of SMF Filter = O.D. of SMN Mixing Elements Length of one (1) SMF Filter = Length of two (2) SMN Mixing Elements O.D of GPD = O.D. of SNM Mixing Elements Length of one (1) GPD = Length of one (1) SNM Mixing Element

Request for a quote

AUGUST TÖPFER & CO. (GMBH & CO.) KG

Germany

Crude glycerine is distinguished by its brown colour and saltysweet flavour which animals enjoy. The applications of crude glycerine include highenergy individual feed and the optimisation of feed rations. Moreover, it acts as a binding agent for floury feeds and as a pelleting agent. As a feed, it promotes feed intake.Feed law stipulates that crude glycerine (GMOfree) may be used for its intended purpose as a feed supplement or individual feed. It provides energy, since its glycerine content is similar to pure starch. It is also recommended for preventing ketosis and stabilising metabolism.

Request for a quote

SD-BEKS, LLC

Russia

Professional feed for rabbits from age of 30 days. Contains only high-quality raw ingredients. Provides organism of an animal with all needed micro- and macronutrients, amino acids and enzymes. The feed is pelleted It decreases the risk of intestinal infections that can occur due to consumption by the animals of low quality, stale or fungi-infected feed. Makes feeding procedure much easier; Ensures fast fattening up; Composition: Barley, oat, offals, carbohydrate PVMF BAKS, sunflower meal, Premix. Vitamin complex: A, D3, E, B1, B2, B3, B4, B5, B6, BC, B12, H Mineral complex: ferrum, cuprum, manganese, iodine, selenium, sulphur Enzymic complex: Enzyme-phytase, calcium (phytase), phosphorus (phytase). Aminoacidic complex: threonine, methionine, lysine, adsorbing agent, antioxidant. Guaranteed performance: ОЭ 290 kKal, Crude protein 16,19%, crude fibre 8%, СА 0,49 %, P 0,50 %.

Request for a quote

HEPROMIJ BV

Netherlands

A high biological value and suitable texture are important pillars in rabbit & rodent feed. A feed must provide sufficient friction for tooth abrasion, especially a complete feed. Furthermore, feed characteristics should match the target animal species, as all rabbit & rodent species are different in their needs, likes and dislikes. And maybe even more than in other categories: the feed needs to look good and smell nice to the owner. Because we can compose a feed completely according to your wishes and ideas, we are able to create a fitting product for every application and rodent species, from mixed feed to pellets.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Pellet feeds - Import exportNumber of results

17 ProductsCountries

Category

- Flour milling - machinery and equipment (4)

- Poultry farming - machinery and equipment (2)

- Weighing and dosing equipment (2)

- Agricultural Production (1)

- Birdseed (1)

- Dietary and organic foods (1)

- Feeds for animal farming (1)

- Films, plastic (1)

- Fish breeding equipment (1)

- Fish processing - machines and equipment (1)

- Packing and packaging - machinery and equipment (1)

- Premix for livestock and poultry (1)

- Wood chips and sawdust (1)