- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- robots for packaging

Results for

Robots for packaging - Import export

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Hugo Beck can claim a decade-long development tradition when it comes to automation. We offer support with our expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines. Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians. Furthermore, various robots systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer‘s needs. Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

As a result of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges, the agri-food industry is one of the four historical sectors of activity that have driven our growth. Among other organisations, we work with the main industrial cheese dairies in the region, which have shown us unfailing loyalty. Beyond special machinery, this collaborative work has helped us to develop specialist expertise in : the use and machining of stainless steel dosing systems for viscous foodstuffs food elevators Applications and projects : conveyor systems stacking systems food elevators process piping robotic units special packaging and wrapping machines dosing workstations cleaning systems control cabinets with PLC Related operations on customers’ sites : maintenance of equipment and infrastructure repairs technical upgrading of existing equipment Safety compliance of existing equipment

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The surfaceCONTROL 2500 measuring system is used for defect detection on diffusely reflecting surfaces. In combination with robots, the surfaceCONTROL 2500 is used for fully automatic defect detection on body shells. This system works according to the method of fringe light projection. By means of a learning process, local form defects such as bumps, dents, etc. are reliably detected, while permissible deviations are tolerated. The surfaceCONTROL systems consist of sensor, robot, computer and software and interface package. Different versions of the system are available, which are configured according to customer-specific requirements. The number of reflectCONTROL sensors and robots required can be flexibly adapted to the required throughput.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

reflectCONTROL Automotive enables the fully automatic inspection of painted car bodies. The robotic systems enable the detection, three-dimensional measurement and classification of typical paint defects such as inclusions, craters, runners, etc. This enables robot-based automatic processing of the defects, up-stream analysis to identify the sources of defects, and laser-based marking for possible manual processing of the defects. The reflectCONTROL systems consist of sensor, robot, computer and software and interface package. Depending on the requirements, different versions of the system are available, which are configured depending on the customer's needs. The number of reflectCONTROL sensors and robots required can be flexibly adapted to the required throughput.

Request for a quote

DAMS MACHINE

Turkey

Sandwiches and burgers which are coming from the cooling unit are placed between the alignment units by two staff manually or automatically with unmanned feeding system. The aligned products are divided into groups of 4.5 and 6, thanks to two valves. The number of products is controlled by the sensors during the separation of the products and the control continues until it is finished. If desired; the slicing process takes place with the slicer system and the products reach the packaging for all grouped products. The products that reach the packaging are transferred to the relevant unit through the robot arm. The packaging unit is controlled by a single servo motor.

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

We are a team of global experts dedicated to producing high-quality health and beauty products. Our specialty is creating and delivering luxury cosmetics, guest bedroom supplies, and bathroom amenities for the hospitality sector. With over 15 years of experience, we have established ourselves as a reliable and favoured private label provider in the industry. Our network of international manufacturing partners boasts impressive production capabilities, including a closed production area spanning 22,000 square metres and a workforce of 210 employees. Their production and packaging processes are fully automated and robotized, enabling them to produce and package up to 86 million units of bottled liquid products, including shampoo, hair conditioner, shower gel, body lotion, and hand soap, per year. Furthermore, they can produce up to 6.6 million units of tubed products, like creams, annually. 12 million pieces per year of plastic bottle production,

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

We are a team of global experts dedicated to producing high-quality health and beauty products. Our specialty is creating and delivering luxury cosmetics, guest bedroom supplies, and bathroom amenities for the hospitality sector. With over 15 years of experience, we have established ourselves as a reliable and favoured private label provider in the industry. Our network of international manufacturing partners boasts impressive production capabilities, including a closed production area spanning 22,000 square metres and a workforce of 210 employees. Their production and packaging processes are fully automated and robotized, enabling them to produce and package up to 86 million units of bottled liquid products, including shampoo, hair conditioner, shower gel, body lotion, and hand soap, per year. Furthermore, they can produce up to 6.6 million units of tubed products, like creams, annually. 12 million pieces per year of plastic bottle production,

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

We are a team of global experts dedicated to producing high-quality health and beauty products. Our specialty is creating and delivering luxury cosmetics, guest bedroom supplies, and bathroom amenities for the hospitality sector. With over 15 years of experience, we have established ourselves as a reliable and favoured private label provider in the industry. Our network of international manufacturing partners boasts impressive production capabilities, including a closed production area spanning 22,000 square metres and a workforce of 210 employees. Their production and packaging processes are fully automated and robotized, enabling them to produce and package up to 86 million units of bottled liquid products, including shampoo, hair conditioner, shower gel, body lotion, and hand soap, per year. Furthermore, they can produce up to 6.6 million units of tubed products, like creams, annually. 12 million pieces per year of plastic bottle production,

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

We are a team of global experts dedicated to producing high-quality health and beauty products. Our specialty is creating and delivering luxury cosmetics, guest bedroom supplies, and bathroom amenities for the hospitality sector. With over 15 years of experience, we have established ourselves as a reliable and favoured private label provider in the industry. Our network of international manufacturing partners boasts impressive production capabilities, including a closed production area spanning 22,000 square metres and a workforce of 210 employees. Their production and packaging processes are fully automated and robotized, enabling them to produce and package up to 86 million units of bottled liquid products, including shampoo, hair conditioner, shower gel, body lotion, and hand soap, per year. Furthermore, they can produce up to 6.6 million units of tubed products, like creams, annually. 12 million pieces per year of plastic bottle production,

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

We are a team of global experts dedicated to producing high-quality health and beauty products. Our specialty is creating and delivering luxury cosmetics, guest bedroom supplies, and bathroom amenities for the hospitality sector. With over 15 years of experience, we have established ourselves as a reliable and favoured private label provider in the industry. Our network of international manufacturing partners boasts impressive production capabilities, including a closed production area spanning 22,000 square metres and a workforce of 210 employees. Their production and packaging processes are fully automated and robotized, enabling them to produce and package up to 86 million units of bottled liquid products, including shampoo, hair conditioner, shower gel, body lotion, and hand soap, per year. Furthermore, they can produce up to 6.6 million units of tubed products, like creams, annually. 12 million pieces per year of plastic bottle production,

Request for a quote

NOVOSIM

Turkey

Special Purpose Machinery refers to custom-designed and built machines tailored to specific industrial processes or applications. These machines are engineered to meet unique production requirements and enhance manufacturing efficiency. Special Purpose Machinery encompasses a wide range of equipment, including automated assembly lines, robotic workcells, packaging machines, and material handling systems. Each machine is meticulously designed and optimized for its intended purpose. These machines are characterized by their versatility, precision, and reliability. They are often equipped with advanced sensors, actuators, and control systems to ensure optimal performance and seamless integration into existing production lines.

Request for a quote

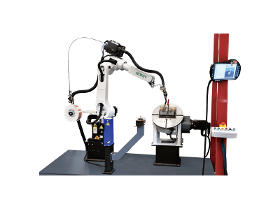

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc and HIWIN bring robot application to a intelligent and remarkable milestone in welding industry through the new weld robot system. System comes with full package including Cut wire Work station w/Multi Task Modular cells To define robot in the COORD export system Pass [Position Register] function to make function infinity

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V350 is designed for handling tasks of maximum heavy loads. It does its job at top speed and is equally suitable for milling and grinding as well as for palletizing, gluing and spraying tasks. The fully automatic high-speed automation enables a significant increase in productivity. Synchromotion: All heavy-duty robots can be combined into complex, fully synchronized systems using the proven Synchromotion ® technology. Heavy weights: can be moved quickly and precisely. Cable routing: optimally protected, no getting caught in robot operations (integrated hose package) Easy to maintain: Easily accessible cable routing The most important technical data at a glance: Number of axes: 6 Working Range (P point): R 2771 mm Max. payload: 350 kg Positional repeatability: +/- 0.2 mm Drive system: AC servo motor Drive power: 8600 W. Weight: 1620 kg

Request for a quote

GIZELIS ROBOTICS

Greece

An IP 67 rating stands for full protection against dust ingress and protected operation against immersion and water penetration (designated by the second digit). Moreover, robotic systems feature smooth finishing, so there are no areas for bacteria build-up, and integrated through-the-arm cabling for problem-free transfer of signals and air, as well as easy, risk-free cleaning with any type of cleaners. Moreover, a food industry-specific grease is used in their spindle reducers. Robotic systems’ main advantage lies in the fact that they may work together with any packaging machinery (carton sealer, film etc) to offer increased operating flexibility to any application. Typically, packaging robots are followed by palletizing robots, however if line speeds are low, packaging robots may also undertake palletizing for additional production cost savings. For all the above reasons, it is easy to understand why all food and pharmaceutical companies apply robots in their production lines.

Request for a quote

BRILLOPAK

United Kingdom

The BRILLOPAK C111 robotic packaging system provides high-speed packing of products into crates and cases. Due to the vertical movement of the robotic arm, the case packing system is able to pack to a depth of 800mm providing the versatility to pack to multiple container types. Ideal for case packing, tray packing and seal punnets. Over 150 packs per minute Precise product placement Multiple products and layer patterns FEATURES & BENEFITS: -High speed case packer: Up to 150 packs a minute. Multiple products with no tooling changeover. -Delicate handling: Using soft flexible grippers or vacuum cups with independent vacuum generators, no damage to product in pick process at high speed. -Very small footprint. -Can pack products up to 5kg weight. -Simple to operate, manage and maintain. ** Click for more **

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

The slewing bearing, also known as slew(ing) ring, is a type of bearing for low-speed and high axial load applications. The slewing bearing is a mechanical component that is used in major industrial sectors. Harbor and deck cranes are one of the ideal applications for using slewing bearings – for example, for container handling. Additionally, for wind turbine blades, the use of slewing bearings ensures the highest level of reliability and efficiency, as required by this sector. APPLICATIONS: Earth Moving Machinery Concrete pumps Civil and Harbor Cranes Wind Turbines Radar Robotics Packaging Logistics Material handling Bottling / filling carousels Rotating tables Polyurethane Injection Systems Drilling Rigs Welding Plants Water Treatment Plants Lunapark Woodworking Machines Marble Cutting Machines Palletizers Aerial Platforms Roller Conveyors / Idle Rollers

Request for a quote

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

With our packaging and palletizing solutions, we robotize the end of the line, which is generally the most inefficient process in production lines, without damaging your products, completely avoiding occupational diseases and possible HSSE risks that can be created by heavy products

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TERCIEL

Luxembourg

Packsoft for your packaging robots. With Packsoft you get the best packaging plans for your items. You can customise them in many ways. And it’s also child’s play to export the coordinates of the palletised objects to transfer all the data to your palletising robot’s PLC. The same applies to the packing operations. This makes it easy to control your robots in a reactive, precise and relevant way ! We also have the solution for multi-product loading …

Request for a quoteResults for

Robots for packaging - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Cosmetics (3)

- Industrial robots (3)

- Automation - systems and equipment (2)

- Sensors (2)

- Bakery and confectionery industry - machinery and equipment (1)

- Bearings - ball, needle and roller (1)

- Food Processing (1)

- Food industry packaging machinery (1)

- Hotel (1)

- Hygiene and toilet products (1)

- Laser - cutting and welding machines (1)

- Motor mechanics - hand tools, non power (1)

- Packaging (1)

- Palletising machinery (1)

- Sealing and wrapping - machinery and equipment (1)

- Software for industry (1)