- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- roller chains

Results for

Roller chains - Import export

CMPLAST

Poland

We produce guides of plastic with high resistance to abrasion. Our offer includes Guides the roller chains Guides the link chains Guides the belts Guides type of PZJ type of PZT ( TAB) type of PZTK (TAB K) type of PPTK (TAB K) type of PPJ type of PPT ( TAB)

Request for a quote

ZIMAS ZINCIR VE MAKINA SAN. TIC. A.S

Turkey

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

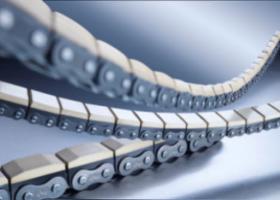

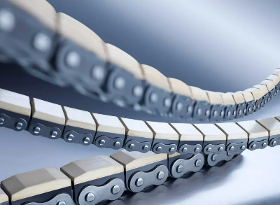

Roller chains with elastomer profiles are ideal for applicationswhere fragile goods require gentle conveyor handling. ELITE chains are used for transporting goods that should not be scratched, such as coated or thin sheet metal, planed timber planks or pipes. The material iwis uses for the ELITE product range is nitrile butadiene rubber (NBR) with a hardness of 80 Shore A. NBR offers the optimum combination of cohesive friction, abrasion resistance and durability. Other profile types are possible for special applications and can be supplied on request. ELITE highlights: • All ELITE chain plates 1 are tapered and shot-blasted; production processes such as fine blanking and ball-drifting ensure a particularly high contact ratio • Seamless, cold-extruded, shot-blasted rollers 2 with extremely regular wall thickness • The standard rubber profile 3 is nitrile butadiene rubber (NBR) with a hardness of 80 Shore A.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

iwis offers a wide range of roller chain products that fulfil the requirements of a variety of conveyor applications. We can supply virtually any special chain version – even the most difficult and complex design – for use in highly diverse application areas: corrosion-free, lube-free, maintenance-free and more.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

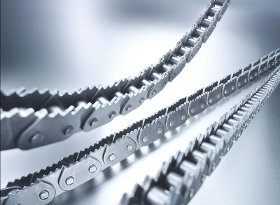

ELITE roller chains with sawtooth plates are extremely wearresistant and designed for optimum fatigue strength. They are used mainly in the wood processing industry for transporting raw timber and sawn planks. ELITE highlights: • Our chains are based on the minimum requirements set out in standard ISO 606. • The steel alloys used are case-hardened and tempered. • Heat treatment of all chain parts is optimized to suit size and application • All roller chains are prestretched to >40% of breaking load as standard • The high quality assurance standard fulfils the requirements of ISO 9001 • Plates 1 are shot-blasted for maximum fatigue strength • Seamless, cold-extruded, shot-blasted rollers 2 with extremely regular wall thickness • ELITE pins 3 are smooth and have an extra hard surface for increased wear resistance

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

We offer you exactly the right conveyor and drive chains to match your transport rollers. Each chain is tailor-made in material and design. This means that you benefit from low maintenance costs and ensure the long-term stability and safety of your goods transport system. The chains are available as yard goods or as ready-to-install, deflected and closed chains. At TRAPOROL you’ll get exactly the right chain and driven wheels to fit your transport rollers on request. We’ll ensure that the material and design of every chain is exactly tailored to your purpose. So you’ll make a big reduction in maintenance costs and gain high performance for your transport system long term. Whether by the metre or ready-to-assemble and enclosed: all the chain wheels supplied are produced in accordance with DIN ISO 606 (ex-DIN ISO 8187) and meet even the highest demands.

Request for a quote

IGUS® GMBH

Germany

Other information Series 2828 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 3838 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 4040 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 2928 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 3938 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 4140 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 5150 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 4040HD Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 400 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050HD Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series R7728 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 100 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R7838 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R8840 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R9850 Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 200 - 1000 mm Pitch: 91 mm E-Tube, swivel lid Series R8840HD Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 400 mm Pitch: 91 mm E-Tube, swivel lid Series R9850HD Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series ATEX/ESD: Excellent match with special material igumid ESD (on request). "Mounted on the side" unsupported application possible High torsional stiffness System E4/4 proven in long travels Other information Series 2828 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 3838 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 4040 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 2928 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 3938 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 4140 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 5150 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 4040HD Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 400 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050HD Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series R7728 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 100 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R7838 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R8840 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R9850 Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 200 - 1000 mm Pitch: 91 mm E-Tube, swivel lid Series R8840HD Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 400 mm Pitch: 91 mm E-Tube, swivel lid Series R9850HD Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining, separating and opening of the E-Chain® and E-Tubes. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. E4/4 "Mounted on the side" - Travel distances over 200 m "Mounted on the side" - Travel distances over 200 m Extensive unsupported lengths for "side-mounted" applications Roller E-Chain® links available (with roller chain) Max. travel distance: 200 - 800 m High torsional stability Manifold interior separation potentials Large accessory kits Typical industrial sectors and applications RTG, quayside cranes, many other types of cranes Composting plants Gypsum, concrete, chemical and mineral plants, as well as agricultural plants Machine tools: unsupported, side-mounted applications Construction machinery ESD applications Heavy machinery Steel works Shipyards Welding plants ATEX/ESD: Excellent match with special material igumid ESD (on request). "Mounted on the side" unsupported application possible High torsional stiffness System E4/4 proven in long travels

Request for a quote

IGUS® GMBH

Germany

- Low-maintenance system for travel up to 100 m - Other sizes and versions available, travel up to 200 m and more with E2 roller e-chains® - Protection against weather and dirt exposure - Cost-effective and fully enclosed complete solution - Standardized and modular design - Simple wall assembly or optional floor mounting - Cable lengths up to 50% shorter than festooning, low-profile installation and no cable junction - Cables are at all times guided with a defined bending radius, and tensile forces are absorbed by the e-chain® - Cables cannot hook, jam, or tear - No slip ring contacts (as is the case on motor drums) -Cables or hoses can easily be retrofitted at any time Reduce electricity costs - direct drive due to scraper, no additional drives needed (as is the case on motor drums) Scraper arm (e.g. as mechanical connection to the scraper carriage) optionally available - we document the situation on-site and will propose a customised solution

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of valve seals, collars, O-rings, drives, piston rods and guides Lubrication of slides, slat-band and roller chains Lubrication of cutting knives as well as of needles and lifters of knitting machines Dismantling of rusted-in parts and removal of oil and greasy soiling Advantages and benefits NSF H1 registered Highly effective due to good creep properties Broad range of uses Displaces water Duolabel Clean the surfaces for optimal effect. Apply OKS 370 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system locations to be lubricated. Spray on evenly OKS 371 spray. Avoid excesses. In as far as available, observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on the basis of the service conditions. Caution: Only mix with suitable lubricants.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Driving and conveyor chains of all designs in open or semi-enclosed operation without a re-lubrication device Roller chains such as motorcycle and bicycle chains Stacker truck chains as well as single or multiple flat-link articulated chains without a re-lubrication device Rope drives and wire pulls; for example, standing, hoisting, traction or winch ropes in hoisting gears, elevators, lifts or mountain railways Flexible drives, bowden and spring cables Moving machine parts exposed to outdoor weathering, such as toothed gearing, guides, closing mechanisms, hinges or sliding surfaces Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Highly adhesive and resistant to throwing off Contains Moₓ-Active for increased performance Excellent wear protection Very good resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral Also available as spray version OKS 451

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Driving and conveyor chains of all designs in open or semi-enclosed operation without a re-lubrication device Roller chains such as motorcycle and bicycle chains Stacker truck chains as well as single or multiple flat-link articulated chains without a re-lubrication device Rope drives and wire pulls; for example, standing, hoisting, traction or winch ropes in hoisting gears, elevators, lifts or mountain railways Flexible drives, bowden and spring cables Moving machine parts exposed to outdoor weathering, such as toothed gearing, guides, closing mechanisms, hinges or sliding surfaces Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Highly adhesive and resistant to throwing off Contains Moₓ-Active for increased performance Excellent wear protection Very good resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of valve seals, collars, O-rings, drives, piston rods and guides Lubrication of slides, slat-band and roller chains Lubrication of cutting knives as well as of needles and lifters of knitting machines Dismantling of rusted-in parts and removal of oil and greasy soiling Advantages and benefits NSF H1 registered Highly effective due to good creep properties Broad range of uses Displaces water OKS 370 is suitable for use with the OKS Airspray system Also available as spray version OKS 371 Clean the surfaces for optimal effect. Apply OKS 370 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system locations to be lubricated. Spray on evenly OKS 371 spray. Avoid excesses. In as far as available, observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on the basis of the service conditions. Caution: Only mix with suitable lubricants.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of fast-running drive chains of all designs for open or semi-open operation without a permanent re-lubricating device, such as motorcycle and bicycle chains Lubrication of hoisting chains such as multirow roller chains or stacker truck chains, as well as single or multiple flat-link articulated chains Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Extreme adhesive strength Extreme wear protection through Moₓ-Active additive Very high resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral For best adhesion, clean the surfaces mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 340 with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Spray on evenly OKS 341 spray. Allow excess to drip off and wait for lubricant to penetrate before resuming operation.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of fast-running drive chains of all designs for open or semi-open operation without a permanent re-lubricating device, such as motorcycle and bicycle chains Lubrication of hoisting chains such as multirow roller chains or stacker truck chains, as well as single or multiple flat-link articulated chains Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Extreme adhesive strength Extreme wear protection through Moₓ-Active additive Very high resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral Also available as spray version OKS 341 For best adhesion, clean the surfaces mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 340 with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Spray on evenly OKS 341 spray. Allow excess to drip off and wait for lubricant to penetrate before resuming operation.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of slow-running rolling and friction bearings, rollers, transport chains or sliding surfaces on kiln trolleys, bakery machines, drying tunnels, foundry machines, boiler firing systems, plastics processing machines for welding and soldering machines etc. Advantages and benefits Highly effective due to optimum temperature-stable silicone grease formula Excellently suited for grease lubricating points subject to high-temperature loading Broad range of uses outside normal grease performance areas

Request for a quote

GURTEC GMBH

Germany

Used for heavy unit goods conveyors Chain-driven and non-chain-driven Dimensions: Roller diameter 20 – 102 mm (3/4” to 4”) Shaft diameter up to 20 mm as standard (3/4”) Roller length up to 1,500 mm (60 ”)

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of temperature-stressed machine parts, e.g. rolling bearings, friction bearings, slideways, chains, rollers or moving parts in hot forming, heat treatment or drying Dry lubrication, e.g. of kiln and rack-truck bearings, bearings of pouring ladles, converters or hot-air blowers at temperatures over 250°C Lubrication of plastic and rubber at normal temperature when the materials concerned are not resistant to mineral oil Advantages and benefits Highly effective due to the strong affinity of the MoS₂ for metals Extremely low friction at highest loading capability Broad range of applications at temperatures up to 200°C as paste, over 200°C to 450°C as dry lubricant Resistant to water, fuels and lubricants, chemicals and hydraulic fluids For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TOSYALI MAKINA A.S.

Turkey

A special link pin design distinguishes hollow pin roller chains from standard roller chains. Hollow pin roller chain links have a similar construction to ISO standard roller chains; They consist of pin, bushing and small pulley, so most chains of this type are compatible with the same sprockets as the corresponding standard chains. Since double chain operation is customary in most applications, we can supply these chains paired. The product range includes various versions of this chain type, such as hollow pin roller chains, hollow pin bushed chains or hollow pin roller chains without bushings, as well as various corrosion-resistant surface finishes (galvanized, nickel-plated, stainless). steel)

Request for a quote

TOSYALI MAKINA A.S.

Turkey

No other type of chain is as versatile as conveyor chains and our product range reflects this versatility. Bushing conveyor chains, roller conveyor chains, hollow pin chains, scraper chains, special conveyor chains for the paper industry and rotating chains are just some of the conveyor chains we can supply. Our product range also includes a wide range of special conveyor chains with straight, curved or U-shaped attachments and much more.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

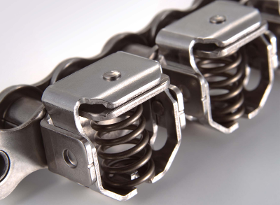

Accumulation chains guarantee trouble-free positioning of the transported goods and almost completely prevent jolts when the belt starts and stops. The idler rollers on each side serve two purposes: first, they engage with the sprocket teeth to transmit power, and second, they support the chain in the guide rail. We offer a wide range of accumulation chains in different performance classes. In addition to classic accumulation chains, we also supply offset low-friction roller accumulation chains, maintenance-free accumulation chains, side spring accumulation chain versions, finger and piece-protected accumulation chains and our cost-effective series

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Our high-performance roller chains combine traditional and modern innovations, making them ideal for forming, filling and discharging processes. These chains are equipped with side-rotating gripper attachments, making them an excellent choice for vacuum seal applications. The designed gripper attachments offer a reliable clamping feature and have special mechanisms to ensure precise positioning. The high-performance springs used in our chain are specially designed to increase their durability and ensure long life in harsh conditions, up to 10 million cycles, even at high speeds. Additionally, the Type M design maximizes the attachment's ability to rotate laterally, keeping your lines running smoother and more efficiently. With these features, our product is an ideal option to make your transactions more reliable and effective

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Maintenance-free roller and conveyor chains offer a much longer service life than traditional low-maintenance/maintenance-free roller chains. The benefits for you are less downtime, longer replacement intervals for machine and system components and, as a result, a significant reduction in maintenance costs. Maintenance-free chains are used where relubrication is impossible or undesirable for hygiene reasons. Roller chains combine excellent wear resistance and durability with corrosion protection and environmental compatibility.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Sawtooth plate roller chains are extremely wear-resistant and designed for optimum fatigue strength. They are mainly used in the wood processing industry to transport raw lumber and sawn planks. Other sawtooth forms are also available on request.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

You will find the right connecting link for every roller chain: Outer link, Inner link, Spring connecting link, Link link cotter pin type, Single crank link, Double crank link.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Roller chains with elastomer profiles are ideal for applications where fragile goods such as coated or thin sheet metal, planed wooden planks or pipes require precise conveyor handling. The chain has a rubber profile that prevents scratches during conveyor transportation. Vulcanized elastomer profiles are available in various standard forms and special profiles are also available on request for special applications.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Long link roller chains correspond, except for pitch, to short link chains according to ISO 606 and comply with the same standard specifications in terms of dimensions. Unlike short link chains according to ISO 606, these chains are designed to be used at lower loads in terms of speed and power transfer.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Rigid chains, chains that prevent bending back or chains that do not bend on one side stand out with their compact design. Thrust chains convert translational motion into rotation and vice versa. They are suitable for transmitting tensile and compressive forces that do not require chain guides. Push-pull chains can be used as a solution in many applications. Wherever the limits of traditional roller chains or drive components are reached (e.g. in tight spaces) push pull chains can provide a versatile solution in many different situations.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Various coating and material options play a critical role in ensuring the corrosion resistance of chains. Our product range includes roller chains made of stainless material with zinc plated, nickel plated and galvanized coating. Zinc plating is often used in outdoor environments and prevents the chain from being affected by oxidation and corrosion. Nickel plating is generally preferred in the food and packaging industries; It extends the service life of the chain by creating a protective layer against acid.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 7000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 4 pieces 50mm diameter pistons Changable outer drum for different weights 4 rows outlet belts. Automatic oil lubrication Variable speed controlsfor main drive and rounding unit Flour duster Dough bunker capacity is 140 kg Safety switches on doors Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 4000pcs/hour) 4 pockets stainless steel dough carrier tray 146 pieces active tray 584 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chain for tray transport Main frame is stainless steel tube Total power 1.1 kW Easy Access for maintenance Safety switches on doors

Request for a quoteResults for

Roller chains - Import exportNumber of results

68 ProductsCountries

Category

- Mechanical transmission systems and components (16)

- Chains (14)

- Machine tools, cutting - parts and accessories (11)

- Silicones (8)

- Lubricants, industrial (3)

- Wood veneer - machinery and equipment (3)

- Bakery and confectionery industry - machinery and equipment (2)

- Palletising machinery (2)

- Pallets (2)

- Storage equipment and systems (2)

- Bearings - ball, needle and roller (1)

- Bearings, roller (1)

- Compactors and crushers (1)

- Construction machinery (1)

- Conveyor systems (1)

- Doors, garage (1)

- Engineering - industrial consultants (1)

- Industrial design (1)

- Metallurgy - machinery and installations (1)

- Profiled sheets - ferrous metal (1)