1ST MACHINE TOOL ACCESSORIES

United Kingdom

Distributor

1ST MACHINE TOOL ACCESSORIES

United Kingdom

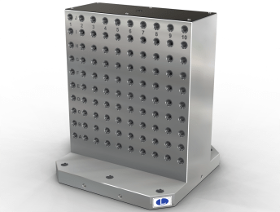

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Threaded Holes for Side-Location Cast iron gridded cube with mounting holes. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. Holes for side location to allow precise loading and setting up of the tombstone.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Change jaws in seconds and complete a full setup in a few minutes Precise loction of jaws means your datum is preserved every time you remove the jaws. Once a job is setup, it stays setup. Machinable workholding means complex shaped workpieces are easy to grip Single station jaws can grip larger workpieces with just a quick jaw change Single Station Machinable Jaw Sets increase the flexibility of your system by eliminating the need to completely switch fixtures for jobs requiring greater holding capacity. Simply QwikChange the jaws and the set-up is ready in minutes. These jaws are compatible with 1030 Qwik-loks and 1030 Multi-Loks and are available in a range of sizes. All jaws are available as sets or individually.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Switch between jaws and faceplates in seconds Clamp more complex workpieces Clamp more components at a time Load faceplates outside the machine for better efficiency Faceplates form the base for a fixture to mount directly to the QwikLOK. They are ideal for complex workpieces that cannot be mounted in soft jaws and also allow smaller workpieces to be clamped in larger quantities. Combine a faceplate with simple workstops and clamps to buld a multi component fixture that can be loaded outside the machine. Add another identical faceplate and you have a manual pallet changing system to virtuallly eliminate loading time.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick change jaws for fast setups Hardened and precision ground for wear resistance and accuracy Ideal for demanding clamping conditions and high clamping forces 6mm step to eliminate the need for parallels Stepped hard jaws for OneLok that fits 5OL1540 and 5OL1550 and well as the previous generation of OneLok. These jaws are hardened and precision ground for strength and accuracy. The BoltFast mechanism means they can be changed in seconds. The 6mm step is precision ground and provides a parallel platform to mount your workpiece.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Up to 50% Coolant Saving Up to 90% Saving in Disposal Improved price for swarf without coolant Improved Housekeeping The Wogaard Coolant Saver collects the cutting-fluid that is normally wasted through the machine tools automatic chip conveyor. The cutting fluid is reclaimed from the chip-container and returned to the machine tool's main tank for re-use. Wogaard can help reduce consumption of cutting fluid and water, reduce the amount of waste fluid collected and disposed of and end fluid leaks that create potential health and safety issues. The Wogaard Coolant Saver is easy to install and is virtually maintenance free. It is driven by the machine tool's onboard coolant pump, so no external energy source is required. Building on the success of the Coolant Saver, Wogaard now also produce an Oil Saver for liquids up to 32 centistokes viscosity. This is recommended for sliding head machines and can be used in any application where neat oil is used.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Pure A100 allows for non-contamination when working with high tempuratures 356-T6 Alloy perfect for heavy work, more durable Abbott aluminium hammers are the perfect alternative to lead, brass and plastic tipped hammers. Single piece cast construction gives maximum solidity and guarantees safety because head cannot separate from handle. The hammers are non-sparking, non-marring and have excellent vibration dampening characteristics that allow the handle to absorb impact forces instead of your hand.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High collection capacity relative to size No reduction in pressure or flow Easy clean Rapid return on investment Eclipse Magnetic Filtration produce a range of products to filter ferrous materials from your CNC machine's cutting fluids and oils. Magnetic filtration is a positive contribution to companies' environmental policies and ISO 14001 accreditation. Magnetic filtration requires no consumable or disposable products. It extracts 100% of ferrous contamination, drastically reducing the use of disposable filter media. Eclipse Micromag is a compact magnetic filter for standard machine filtration and smaller wash stations. Micromag is compact in size but has massive holding capacity. Units hold 1kg, 2kg, and 4kg of contamination respectively. Micromag is available in a range of sizes to suit a range of applications up to a pressure of 80 bar and a temperature of 140 degrees. Specific Micromag units are selelcted for an application based on required flow rate

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Eclipse’s patented magnetic filtration or magnetic separation systems are the ultimate in filtration technology, providing, quality and environmental benefits. The Filtramag is the ultimate in filtration technology, its’ high intensity magnetic cores make it 1005 effective for use with materials which have lower magnetic permeability such as tungsten carbide and cast iron. With a stainless steel construction it is ideal for use in harsh chemical environments and wash systems. Patented design. Easy installation. Unique dual flow technology™ maximises collection capability. Operates at up to 20 bar. Removes both magnetic and non-magnetic contamination. Minimal pressure drop. In-line connections. Ideal for use in harsh chemical environments. The dual chambered design means that fluid is exposed to the high intensity magnets for the maximum time thus ensuring almost 100% of contamination is removed on first pass through the filter. High intensity magnetic cores ensure particle

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Is a self-contained filtration and fluid recovery system. The fully automated unit minimises fluid loss during cleaning and is ideal for 24/7 high volume single or multi-cell machining applications providing: Unique Dual Flow Technology ™ – maximising collection capability No user intervention required Suitable for harsh chemical environments PLC compatible Ultra-fast automated cleaning No reduction in pressure or flow Rapid return on investment Built in fluid recovery system Flow rates of up to 1800 litres per minute Double Automag Skid units are available for large flow rate/heavy contamination applications. Contact us for further information.

Request for a quoteDistributor

Unit 1, The Headlands

Downton

SP5 3JJ Salisbury - United Kingdom

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

EMSIL TECHTRANS SRL

Romania

Emsil Group is capable of manufacturing complex products based on our Customer's drawings and specifications. Over the years we have expanded our capacities and capabilities into manufacturing most if not all process steps. Today, these capabilities allow us to manufacture turnkey projects at our 3 production sites and also provide additional services through our extensive network of collaborators. The industries in which we are active are: vacuum, energy, oil & gas, naval, aerospace and metallurgy.

Request for a quote

EMSIL TECHTRANS SRL

Romania

Emsil Group is capable of manufacturing complex products based on our Customer's drawings and specifications. Over the years we have expanded our capacities and capabilities into manufacturing most if not all process steps. Today, these capabilities allow us to manufacture turnkey projects at our 3 production sites and also provide additional services through our extensive network of collaborators. The industries in which we are active are: vacuum, energy, oil & gas, naval, aerospace and metallurgy. Types of products we manufacture Glass coaters and packaging machines in the vacuum industry Baseplates and chassis for the oil & gas and energy industries Winches and crane components for the naval industry Pressure vessels from carbon steel and stainless steel PROJECT MANAGEMENT DESIGN & ENGINEERING CUTTING ASSEMBLING & WELDING PRESS BREAKS FOR BENDING ROLLING MACHINING HEAT TREATMENT SURFACE TREATMENT FINAL ASSEMBLY & AUTOMATION CUSTOM PACKAGING & DISPATCH

Request for a quote

EMSIL TECHTRANS SRL

Romania

Retrofit your machines to enjoy the modern age

Request for a quote

EMSIL TECHTRANS SRL

Romania

displaceable rotary tables are intended for increasing the technological possibilities of the horizontal boring and milling machines with moving column

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free