A. EBBECKE VERFAHRENSTECHNIK AG - TECHNIKEXPERTE FÜR SCHÜTTGUT & SCHÜTTGUTVERARBEITUNG

Germany

Service Provider

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Logistics All-round logistics service for your products As well as production, we are also happy to provide logistics for you on request. With sampling, sample shipping, packaging and labeling, storage, loading and shipment management we offer an individualized all-round service for your goods. This all-round service guarantees you a smooth availability of your products without having to store them yourselves. On request, we hold a minimum stock of your products available. If you wish, we can process customer orders from your customer care centers directly for you. We pack the products processed by us according to your CI requirements in the container of your choice. This way our company can't be seen in anyway, not even on the delivery note. In other words: With our comprehensive logistics services you can outsource your transport structures to us cost-effectively. In the center of Europe We offer our logistics possibilities at our sites in Schöneck, Bruchköbel near Frankfurt am Ma

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Bag Fill Modern, flexible, customer-oriented Technical data Container types Valve bags, open bags, cardboard boxes, drums and fiber drums Container fastening: Plastic bags, welded; paper bags, sewn; valve sacks, valve welded or folded; cardboard boxes / drums tied with liners so they form goosenecks and then fastened with clips Product-contacting parts: Stainless steel, partially electropolished Feeding: From 100 m³ silos, alternatively from Big Bags, octabins, bags or cardboard boxes Number of filling lines 12 Contract filling plants Dosing screw scales, turbine packers, compressed-air packers, vacuum packer, downpipe packers Supplementary: Position of scrap metal boxes as transport containers in reuse of transportation boxes Areas of application Filling of cardboard boxes Filling of fiber drums Filling of valve bags and open bags (5-25 kg bag weight) Filling and palletting of special bags Filling of thin-walled bags (EVA bags) Prospect for download

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Big Bag Fill The filling plant for Big Bags and octabins Our Big-Bag filling scales enable the external assignment of filling services onto calibrated Big-Bag scales from storage silos bags or drums. We offer short term useful and flexible filling capacities as a replacement or supplement to your own filling plants. Technical data Big Bag sizes: 0.5-2.5 m³ Weight ranges 50-1,500 kg Product-contacting parts: Stainless steel Feeding: From 100 m³ silos, from palletted bagged goods and drums Number of filling lines 4 Areas of application Filling of Big Bags from silo Filling of Big Bags from bags Refilling of various sizes of Big Bag De-aeration of the product, with subsequent Big-Bag filling Refilling with protective screening Refilling with crushing of agglomerates Refilling with homogenization Refilling with additional admixture of one or more components Refilling with metal detection Prospect for download

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Fine Mill The solution for fine grinding Ebbecke Verfahrenstechnik AG is your specialist for demanding tasks in the area of ??contract grinding. The fine grinding plants used enable the dissolution of agglomerates as well as the breaking up of solid grain structures including even the very finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. Accordingly, they comply with all the strict specifications and hygiene standards of the of food, pharmaceuticals and cosmetics industries. Technical data Target fineness: 1.0-5,000 µm Plant types: Classifier mills, air jet grinding plants, spiral jet grinding plants, pin mills, cross beater mills, hammer mills, Fitzmill, screen mills, disc mills, graters, crushers, cryogenic grinding, nitrogen overlaid plants Product-contacting parts: Stainless steel Delivery in: Bags, bales, Big Bags, octa

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Cryogenic Mill The solution for fine grinding temperature-sensitive products. Our cryogenic grinding plants enable fine grinding of lubricating and temperature-sensitive products. This not only results in a technically perfect grinding but in addition thermal damage of the ground material and resulting grinding losses are prevented by the cryogenic grinding. All plants are designed with swivel screw coolers and liquid nitrogen cooling, appropriate dosing devices, separators as well as bunkers as closed plants. Technical data Target fineness: 10-2,000 µm Plant types: Pin mills, cross beater mills Product-contacting parts: Stainless steel Cooling: By liquid nitrogen Delivery in: Bagged goods, Big Bags, oktabins, drums Feeding: Via feeding stations, metering screws and vertebral screw coolers Filling into: Bags, drums, Big Bags, cardboard boxes and special containers Areas of application Fine grinding of resins Fine grinding of foodstuffs Fine grinding of seeds Fine grindi

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Drug Mill The economic solution for grinding your natural products The drug mill used by us enables an economical external grinding of leaf drugs, herbs and plant roots for our customers. This way our clients save having to invest in their own, only mills that would only be fully utilized seasonally – at the same time they remain flexible with the production of teas, remedies or natural cosmetics. Technical data Throughput: 0,5-3 to/h Target fineness: 1-15 mm Product-contacting parts: Stainless steel Cleanability: Completely cleanable Grinding plant: Granulator with screen insert Feeding: Via bunker with clearing device and double shaft screw Container: Feeding as bagged goods, bales, Big Bags, octabins or in drums Areas of application Grinding of drug precursors Grinding of willow bark Grinding of St. John's wort Grinding of tea leaves Grinding of plant roots After grinding, filling in Big Bags or other containers Prospect for download

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Plastic Mill The solution for the production of plastic powder Our fine grinding plants for plastic granulates enable the grinding of a wide variety of plastic granulates including even the finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. The ground goods can be processed on site or poured directly into the container specified by the customer. Technical data Target fineness: 200-1,000 µm Plant types: Disc mills, pin mills, granulators, cryogenic grinding plant Container: Bags, Big Bags, octabins, drums or drums Feeding from silo possible Filling from silo vehicles is possible Areas of application Fine grinding of LDPE Fine grinding of polypropylene Fine grinding of polystyrene Fine grinding of polyamide Fine grinding for simultaneous de-dusting of the finished product Fine grinding of EVA under cryogenic conditions

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

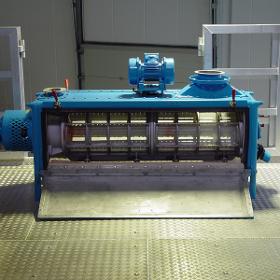

Centrifugal Screening Vibration/rotation screening plants – the solution for fatty, oily and light products The vibration/rotation screening machine enables the screening of products that are difficult to screen and that would smear up screen inserts. This relates in particular to fat-containing and oiled products and products with very light bulk weights. For this purpose, an eddy current is generated by a wing rotating in screening half shells. Through targeted vibration overlays of the the outer screen fabric a seal of the fabric is prevented, thus ensuring a high-quality screening even for procedurally sensitive products. Technical data Screening area 0.5 or 0.9 m² Mesh width: 75-10,000 µm Product-contacting parts: Rustproof materials Cleanability: Completely cleanable Number of fractions: 2 Product feeding: Extractable dosing screw Throughput: Depends on mesh size and the product Number of plants: 2 Areas of application Grinding of soft products without temperature i

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Linear Sieve The flexible and adaptive screening system The linear sieve enables contract screening with maximum flexibility. Through the adjustability of the stroke length, the variable tilt adjustment of the screening fabric and the motor speed, which is controllable by frequency converter, the widest variety of products and grain sizes can be a screened perfectly. A continuous-cleaning screen insert de-duster reduces blocking of the screen fabric. Thanks to the long-stroke agitation of the screen fabric the best possible selectivity is achieved, at the same time the long-stroke movement plan prevents elongated particles from standing up. The result is a greatly reduced number of outsize particles in the final product. There is a revolutionary new development in our factory in Schöneck: This combined screening sifting plant which is equipped with an air classifier enables the screening out of coarse material with simultaneous sifting of long-fiber constituents of the product. This

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Roll Compactor The roll compactor plant – the solution for low-dust products With our roller compactor plants powdered components especially low in dust can be condensed into granulate. In this case, several components with divergent properties can be mixed and granulated together. This way our roller compactor plant allows an efficient complete production of granulates from powder mixtures. The plants used at Ebbecke Verfahrenstechnik are equipped with pre-and fine granulators, while at the same time fine particles are fed back via post-screening. All granulation plants are continuously adjustable in their pressing force, in addition part of the plants are equipped with pre-compression by means of a vacuum intake. Technical data Granulation performance: 5 - 500 kg/h Product intake by means of: Pre-compressor screw (two-step) and vacuum intake (partial) Product-contacting parts: Stainless steel Feeding from: Big Bag, oktabin, bagged goods, cardboard boxes, drums Platform const

Request for a quoteService Provider

Keltenstraße 16

63486 Bruchköbel - Germany