- europages

- >

- Packaging

- >

- ASCO CARBON DIOXIDE LTD

- >

- products

ASCO CARBON DIOXIDE LTD

Switzerland

Manufacturer/ Producer

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCOJET 1208 features a new modern frame design and selfexplanatory pictogram. This powerful blasting machine is very easy to use and is particularly suitable for use in industries. The newly integrated grounding roll and protective grating in the pellet hopper guarantee safe handling during the blasting process.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCOJET 1701 is a compact, mobile dry ice blasting unit featuring a handy one hose system which has been specially developed to maintain efficient cleaning with contaminants which are harder to remove. This powerful unit is suitable for industrial end users like foundries, tyre manufacturers, food industry and printing industry who require high performance and easy handling.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCOJET 1708 Combi Blaster is the first ASCOJET dry ice blasting unit which allows the use of an additional blasting material in the dry ice stream and therefore offers the best combination of gentle cleaning with dry ice pellets and the additional abrasive effect of a carefully selected additive. This dry ice blasting unit is powerful, handy, minimal secondary pollution and reduced noise emission thanks to low air consumption – The ASCOJET 1708 Combi Blaster is perfectly suitable for industrial end users of all kinds.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO dry ice blasting is not just a cleaning process but a package of complete solutions. Over 20 years of experience in the dry ice blasting field and a highly motivated team have led ASCO’s dry ice blasting technology to the place where it stands now. With the ASCO dry ice blasting technology we follow ASCO’s philosophy to provide complete and individual solutions tailored to the specific needs of our customers. Such individual solutions can start with a single dry ice blasting machine and lead to more comprehensive cleaning system that increase overall quality and flexibility and give production and cost savings. Our team and a worldwide network of sales partners guarantee individual consultation and service. We will be pleased to also find the right solution for you.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO’s innovative ASCOSORB CO2 Stack Gas Recovery Technology turns your vent flue gas into a usable and profitable source of CO2. CO2 gas won by an ASCO Stack Gas Recovery System is a byproduct of flue gas production from boilers as well as from other flue gas sources offering an economic CO2 source to any CO2 consumer or reseller. ASCO, as a provider of complete CO2 solutions, offers CO2 Stack Gas Recovery Systems with various capacities. Reliable CO2 source Reliable and economic source of CO2 to the end user as opposed to self burning processes or purchasing liquid CO2 Reduction in energy usage The ASCOSORB Technology brings to the ASCO CO2 Stack Gas Recovery Plant tremendous reduction in total energy usage offering greatly reduced OPEX only approx. 1.3 MWth / MT produced CO2

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO’s innovative CO2 Gas Recovery Technology turns your vented byproduct gas into profitable CO2. Be it for an alcoholic fermentation process (e.g. breweries, ethanol operations, distilleries or wineries), other industrial sources (e.g. ammonia production or hydrogen reforming) or natural sources, ASCO will find your individual CO2 recovery solution. ASCO’s ByProduct CO2 Gas Recovery System can make this opportunity a reality to those interested in developing a business case and realizing the potential rewards of recovering CO2 gas from these sources. Our systems, manufactured of the highest quality in materials and workmanship, offers extremely low operating costs placing the least OPEX against CAPEX providing a far greater return on investment. Sources ASCO CO2 Gas Recovery Systems are applicable to a variety of sources

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO CO2 Gas Revert Recovery Systems are engineered to efficiently recover the revert CO2 gas from ASCO Dry Ice Pellet and Block Machines which normally direct the revert (flash) gas to the atmosphere. When dry ice is produced the conversion rate from liquid CO2 to dry ice is approx. 4045 %. This means 5560 % is lost to the atmosphere. This conversation rate is a physical fact and therefore, unfortunately, not to change. With a CO2 Revert Recovery System, however, most of the CO2 can be recovered which leads to a final conversion rate of approx. 9095 %. This way, the dry ice production costs are reduced up to 50 %.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

We offer Atmospheric CO2 Vaporisers in various capacities with either stainless steel or copper tubings. The atmospheric ASCO CO2 Vaporiser has been developed to drastically reduce CO2 vaporisation costs. Ambient air, which is available at no cost, is used to achieve energy savings of over 95% compared to standard electric vaporisers. The fans are automatically controlled temperature dependent and only work if a consumer equipment is in operation. As each vaporiser is supplied prepiped and prewired, installation can be made within minutes. Bases for floor mounting are included. In addition to our standard models, we offer individual solutions of modern and easy to maintain CO2 vaporisers. In accordance with your requirements, we provide you with a suitable CO2 vaporiser. Available capacities 200 kg/h, 300 kg/h, 500 kg/h und 1‘000 kg/h (440 lb/h, 661 lb/h, 1102 lb/h, 2205 lb/h)

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

In addition to its standard models, ASCO offers a large number of modern and easy to maintain CO2 vaporisers. In accordance to your requirements, we provide you with a suitable model. In order to meet every customer's need, we have different types, technologies and capacity ranges from 100 to well over 2000 kg/h. ASCO offers following technologies Cold water circulation Electric water bath heater Gas heated water bath Electric Atmospheric Individual solutions Costoptimised applications Reliable operation Minimal maintenance Customised adaptations to local conditions Expert knowhow Outstanding customer service

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

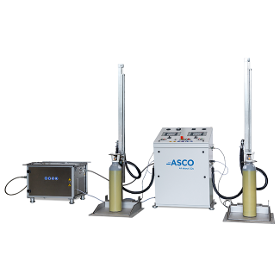

The ASCO LH900 Liquid CO2 Filling Pump has been developed as an universal unit for filling high pressure CO2 cylinders by weight. Like all ASCO Equipment, the Cylinder Filling and Weighing System is thoroughly factory pretested before despatch. Thanks to the separate control unit, the pump can be placed in a different location. Easy operation Switch on your ASCO LH900 and the unit automatically tares itself to „0“ which will show on the indicator display. After placing a cylinder on the platform, the display will show the accurate tare weight of the cylinder, allowing the operator to check whether the empty cylinder weight is correct. The chosen filling weight can now be set on the display by pressing the relevant keys (when filling the same size of cylinder, the filling weight needs only be entered once). When the desired filling weight is reached and displayed, the solenoid valves of the ASCO LH900 will automatically switch to run the system in bypass.

Request for a quoteManufacturer/ Producer

Industriestrasse 2 / Postfach 326

8590 Romanshorn - Switzerland