BELIMED LIFE SCIENCE AG

Switzerland

Manufacturer/ Producer

BELIMED LIFE SCIENCE AG

Switzerland

The Belimed Life Science Saturated Steam Sterilizer (Process 6050) is suitable for a wide range of applications in the pharmaceutical and biotechnological industry and in laboratories. The saturated steam processes are optimized for solids and liquids in open containers and are based on many years of experience in the development and optimization of sterilizers that meet the highest standards. The sterilizer is typically used for the sterilization of production items such as bottles, tubes, pipe connections, metal containers, containers, cages, textiles and clothing. Optionally, the sterilizer can be extended with the process double jacket cooling with supporting pressure during cooling (process 6050 / 6065).

Request for a quote

BELIMED LIFE SCIENCE AG

Switzerland

The LST-V steam sterilizers are designed for the sterilization of solid, porous and difficult to ventilate goods as well as for the decontamination of waste in laboratories. They meet the European Pressure Equipment Directive 97/23/EC and the DIN 58951-2 standard for equipment groups A, B, C, D1, D2 and E1. The steam sterilizer of the LST-V series with vertically running sliding doors is characterized by its compact and ergonomic design. The LST-V is universally applicable for: Waste Glassware Porous, vacuum-tight goods Liquids in open or closed containers Culture media Animal cages, food

Request for a quote

BELIMED LIFE SCIENCE AG

Switzerland

The PST sterilizer is completely designed and constructed according to customer requirements. The sterilizer is based on 15 standard cubic chamber sizes ranging from the compact masses 6-6-6 (H X W X D in dm) to 18-10-15 (H X W X D in dm) which can be individually adapted to the sterilization task. The saturated steam processes are optimized for solids as well as liquids in open containers and are based on many years of experience in the development and optimization of sterilizers for highest demands. In addition, steam-air-mixture processes for sterilization of liquids in closed containers are also possible.

Request for a quote

BELIMED LIFE SCIENCE AG

Switzerland

The GMP-compliant, compact Belimed Life Science Pharma cleaning system was specially developed for the preparation, cleaning and drying of components in contact with the product for the production of drugs or experiments in laboratories. The washer characterized by an uncompromising hygienic design, simple operation and low-maintenance construction. The design of the pharmaceutical cleaning system and the cleaning processes have been optimized for the highest demands based on many years of experience.

Request for a quote

BELIMED LIFE SCIENCE AG

Switzerland

The Belimed Life Science Pharma-Washers were specially developed for the preparation, cleaning and drying of components in contact with the product for the production of drugs or experiments in laboratories. They are characterized by an uncompromising hygienic design, simple operation and low-maintenance construction. The design of the Pharma-Washer and the cleaning procedures have been optimized for highest demands based on many years of experience. Typical applications for the pharma-washers are the cleaning of components in contact with the product in the production, filling and packaging of pharmaceutical products, the cleaning of glassware and equipment for laboratories and the cleaning of transport containers and equipment for use in clean rooms.

Request for a quote

BELIMED LIFE SCIENCE AG

Switzerland

Designed as a cleaning system for containers, drums, pallets and other large-sized vessels, the PH 880.2 is part of an extensive model range (PH 820.2, PH 840.2 and PH 860.2). The tailored operational sequences for professional pharmaceutical processes maximises efficient throughput. Based on standardised technical design and years of Belimed Life Science’s experience in automatic cleaning, the PH washer range covers a wide range of cleaning requirements and features harmonised construction characteristics throughout the various models. The PH 880.2 combines highest possible component standardisation with the necessary design flexibility to achieve best possible adaptation of the machine to the requirements of the production process.

Request for a quote

BELIMED LIFE SCIENCE AG

Switzerland

The washer and disinfector WD 200 was developed for professional use in laboratories. The device is characterized by a storage capacity of up to 12 DIN instrument trays, a small footprint - only 68 cm wide -, low media consumption and the highest quality of the washing chamber and machine components. The WD 200 has been developed in accordance with the latest EN ISO 15883 guidelines, is easy to operate and allows a wide variety of products to be processed quickly and safely. Low media consumption - high productivity With the unique "Dynamic Filling" (Dynamic Filling System) up to 20 % water, detergent and energy can be saved. The optional exhaust air heat recovery with deionized water pre-heating reduces energy and media consumption by an additional 20 %. The clever design of the new Belimed Life Science ECO load carrier generation also ensures improved water management and even better cleaning results. On average, 10% less water is required than with conventional load carriers.

Request for a quote

BELIMED LIFE SCIENCE AG

Switzerland

Developed according to the latest EN ISO 15883 guideline, it ensures the safe cleaning, disinfection and drying of your products. In short batch times to perfect quality. In instrument reprocessing, Belimed Life Science systems ensure a high throughput and achieve perfect cleaning quality with short program times. This is made possible, among other things, by a high washing performance and the specially developed high-performance drying system. The deionized water preheating system can reduce process times by around 14 minutes. Place of application The WD 290 is suitable wherever large quantities of small products have to be handled efficiently. Thanks to its high machine capacity and automation options, it is the right choice. The single-door version, on the other hand, can be used wherever space is limited and there is no separation of clean and unclean products.

Request for a quote

BELIMED LIFE SCIENCE AG

Switzerland

Extensive practical experience and close cooperation with customers and planners show us that less and less space is available for cleaning. In response to this fact we have designed the WD 390 PH with space-saving, shorter cleaning and drying cabins and shorter machine infeed and discharge distances. The WD 390 PH with its cleaning and drying cabins enables short washing cycles and at the same time a higher throughput of washed goods. The Modular Concept The WD 390 PH is equipped with five compact cabins that perform various functions such as cleaning, rinsing and drying in short wash cycles, enabling efficient cleaning and high throughput. In addition, the WD 390 PH offers access for maintenance and service from only one long side, as all units are arranged for easy servicing.

Request for a quote

BELIMED LIFE SCIENCE AG

Switzerland

The floor-level loadable WD 750 large-scale cleaning system is the ideal solution for cleaning and drying large non-critical items from pharmaceutical production, the food industry or the cosmetics industry. The construction in a hygienic design with few gaps and dead spaces meets GMP requirements such as complete self-draining of the piping, pump, tank, valves and fittings as well as all surfaces in contact with the product with inclination (chamber roof, chamber floor).

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

WESPY INDUSTRIAL PARTS WASHING MACHINES

Turkey

The part washing machine is designed to easily clean dirty parts with a small size and complex structure in the shortest time possible. Thanks to its brush, the person performing the washing process can carry out any kind of cleaning in the dirty part in detail. It is an ideal parts washing machine for using in small areas.

Request for a quote

EC PLAZA

South Korea

As the world’s global leader in semiconductor equipment manufacturing, VISION SEMICON has cease-lessly worked with the management philosophy of merging future-oriented technology with today’s technology in hopes of providing happiness and contentment for all humans. As the result, VISION SEMICON has received reviews from clients worldwide for its plasma treatment process equipment, which is the most important procedure in semiconductor production process, oven system and unmanned semiconductor production process.

Request for a quote

CRYOSNOW GMBH

Germany

• For large surfaces and stubborn contaminations • Powerful round nozzles • Flat nozzles with blasting widths of up to 100 mm (4") • Available as Desktop and Trolley • No power supply, as driven pneumatically

Request for a quote

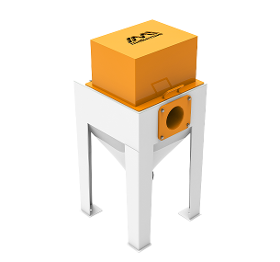

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to clean jet filter bags that lose their filtering function over time due to dust particles

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free