- europages

- >

- Rubber products

- >

- BOSCH MANUFACTURING AND SERVICES BELGIUM

BOSCH MANUFACTURING AND SERVICES BELGIUM

Belgium

Manufacturer/ Producer

BOSCH MANUFACTURING AND SERVICES BELGIUM

Belgium

From standard to tailor-made rubber compounds. Benefit from our high quality rubber compounds as well as our in-house R&D knowledge and 45 years of expertise. You can rely on our well proven know how and experience in development and production of both synthetic as natural rubbers composing of polymers, carbon black and a wide range of possible additives. -EPDM - Chloroprene Rubber (CR) - Natural rubber (NR) - ...........etc. Combinations of different rubber types.

Request for a quote

BOSCH MANUFACTURING AND SERVICES BELGIUM

Belgium

we can safeguard a very high level of process control in our extrusion production lines because our vulcanization process is done in a salt bath. This means the temperature of vulcanization is stable and independent of external conditions. This way, we can produce rubber profiles of a very consistent and high quality. Co-extrusion: we can produce 2 rubber types (eg hard and soft) into 1 final product High geometrical accuracy High surface quality Can be tailored to customers' needs Possibility to apply different types of coatings (our patented PPC coating, graphite coating or chlorinated).

Request for a quote

BOSCH MANUFACTURING AND SERVICES BELGIUM

Belgium

We have proven experience in (seamless) injection molding, both on natural as synthetic rubber types. Tooling design is also done in-house.

Request for a quoteFor over 40 years we are developing and producing high quality rubbers in Tienen (Bosch Manufacturing and Services Belgium). Within the Bosch Group, we act as the global Lead Plant and take charge, not only when it comes to the development of new and optimized rubber compounds but also in the development and introduction of new and innovative production processes.We are open to collaboration with external partners and create synergies for scaling up and industrialization of their business. Compounding: We can rely on our well proven know how and experience in development and production of both synthetic as natural rubbers composing of polymers, carbon black and a wide range of possible additives. Having all this knowledge in-house offers the opportunity to specifically design the rubber compounds according to the customer needs and demands eg UV resistance, ozone, ... From raw material to compound to end product with the required characteristics (heat resistance, compression set, sealing quality, ...) Co-extrusion: we can produce 2 rubber types (eg hard and soft) into 1 final product ○High geometrical accuracy ○High surface quality ○Can be tailored to customers’ needs ○Possibility to apply different types of coatings (our patented PPC coating, graphite coating or chlorinated) Injection Molding: We have proven experience in (seamless) injection molding, both on natural as synthetic rubber types. Tooling design is also done in-house.

Website

Manufacturer/ Producer

Hamelendreef 80

3300 Tienen - Belgium

Company info

Key figures

-

- Company headcount

- > 500

-

- Sales staff

- 1 – 10

-

- % of export sales

- 80%

Organisation

-

- Year established

- 1974

-

- pages.epage-home.site-status

- Registered office – Subsidiary

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Payment methods

- Swift transfer

Delivery areas

Terms of delivery (incoterms)

- Purchaser

- Shared

- Vendor

Activities of BOSCH MANUFACTURING AND SERVICES BELGIUM

- Rubber products

- rubber compounds

- extruded rubber products

- moulded rubber products

- research and development

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

URM - UNIVERSAL RUBBER MANUFACTURING NV

Belgium

URM Gasket & Seals is a leading manufacturer of high quality neoprene gaskets, neoprene seals and neoprene washers for a wide range of industries across the country. No matter if your project calls for a single prototype or large production runs; no matter if the gasket, seal or washer is simple or complex, we are committed to our promise of providing our customers with neoprene gaskets that have been accurately cut to the tightest tolerance and delivered with the quickest turnaround in the industry. Good impermeability to gases doneGood ozone resistance doneGood resistance to weather More information Neoprene rubber exhibits good chemical inertia, and is commonly used in electrical installations and weather sealing applications. Neoprene is particularly suitable for use with water; be that salt or fresh water – although from drinking (potable) water it is better to use EPDM rubber. Neoprene has good resistance to ozone and sunlight.

URM - UNIVERSAL RUBBER MANUFACTURING NV

Belgium

Urm produces valves tailored to your exact specifications. These Rubber metal valves can be made with metal such as brass, steel or stainless steel and can be bound to all elastomer types. Precisely manufactured doneHigh endurance parts doneBonds on any type of metal More information These rubber metal parts can be manufactured on your exact specifications. Based on sketches and schematics URM produces your part to the highest detail. Universal Rubber only works with the highest quality of compounds to create high quality rubber metal bonds and will always produce rubber parts to completely fit the customer’s needs. Industry use Any type of industry where high quality durable rubber needs to be used.v

URM - UNIVERSAL RUBBER MANUFACTURING NV

Belgium

URM Rubber metal connections are most commonly used to filter vibrations and stop resonance. Metal such as brass, aluminum, steel or stainless steel can be offered with bonding to all elastomer types. URM Offers only the best quality of elastomers to ensure high endurance and parts lifetime. donePrecisely manufactured doneBuilt to filter vibrations doneBonds on any type of metal More information These rubber metal parts can be manufactured on your exact specifications. Based on sketches and schematics URM produces your part to the highest detail. Universal Rubber only works with the highest quality of compounds to create high quality rubber metal bonds and will always produce rubber parts to completely fit the customer’s needs. Industry use Any type of industry where rubber to metal vulcanized parts are used.

URM - UNIVERSAL RUBBER MANUFACTURING NV

Belgium

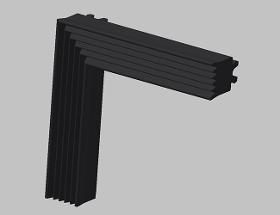

We offer a wide variety of high quality L shape and angle extrusions. They provide excellent sealing as well as protection in a wide range of applications. We manufacture these profiles in either EPDM or neoprene depending on the profile you select. We are able to supply a diverse range of shapes and sizes to match any requirement. Highly durable doneExcellent weather resistance doneGood tensile strength More information These ramp shaped profiles are the perfect product to use with any rubber mats or artificial grass products. In applications involving a slippery surface the angle extrusions help to hold the mats in place. This reduces many potential hazards involved with mats slipping underfoot. The ramp edge also greatly reduces tripping hazards. It provides a gentle gradient from the ground surface to the top surface of the mat.

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free