BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Manufacturer/ Producer

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

The stenter is the heart of textile finishing. It develops more and more into a multipurpose line for the production of technical textiles and other webshaped materials. Several thousands of BRÜCKNER stenters are in use all around the globe. Every day they are stentering, drying, heatsetting, functionalizing and coating incountable meters of the most different fabric types. Since many decades BRÜCKNER stenters stand for highest quality and performance and are producing sustainably and energyefficiently. The most important benefits of these stenter frames are highest drying performance and process control matching any type of fabric due to the technically mature and proven splitflow air circulation system, very homogeneous air flow and temperature distribution due to alternately arranged thermo zones, very low specific energy consumption, extremely robust chains, chain rails, pin bar carriers and clips, needing only little maintenance.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

The relaxation dryer serves for the drying, relaxing and shrinking of knitted fabric in tubular and openwidth form but can be used also for the treatment of woven fabric. Residual shrinkage is reduced to a minimum and the fabric gets a very good dimensional stability across the length and width and a fleecy, soft and voluminous touch. Depending on the customer’s requests and the needed capacity, the dryer is available with one, two or three fabric passages. This dryer is mainly used to finish articles made of natural fibres such as cotton, viscose and wool but also of blends thereof or blends with elastane, polyamide or polyester. Such fabric qualities are mostly further processed for underwear (ribware), nightwear (Interlock), polo shirts (Piqué), Tshirts (single jersey) or sweat shirts (fleece or sweatware). The residual shrinkage is reduced to a minimum and the fabric gets a very good length and width stability and a fleecy, soft and voluminous handle.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Compacting is the last finishing process after relaxation or drying and has thus decisive importance for the residual shrinking, the hand and the aspect and the shine of the fabric before cutting and makeup. The BRÜCKNER compacting calender is characterized by an extremely short fabric path, an optimum traction control and a sophisticated drive technology allowing high production speeds with consistent fabric quality. Depending on the fabric type and the quality requirements, BRÜCKNER can offer the following compacting solutions two felt belt compactors arranged one behind the other, rubber belt shrinking unit according to the Sanfor principle, rubber belt shrinking unit with downstream arranged felt belt compacting calender. In addition, the following units can be integrated into the compacting line equalizing frame for the overspreading and width control, straightener, steamer unit, edge cutter (knife or scissor type).

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Finishing on a sanfor line provides the fabric with a more stable structure, a silklike shine, a smoother touch and minimum residual shrinkage. The rubberbelt compacting line is made for the sanforisation and compacting of woven fabric and some kinds of knitted fabric, in combination with a felt belt calender the fabric gets on these lines additionally a special touch. The benefits are among others optimum residual shrinkage due to the hightech drive concept, stabilisation of the fabric structure, silklike shine, soft fabric touch, absolutely constant shrinkage due to a new automatic shrinkage control system available as option, production speeds up to 100 m/min are possible, extended service life of the rubber belt due to the larger diameter of the compacting rollers and an optimised rubber belt cooling system, integrated menudriven rubber belt grinding process, minimisation of vibrations, all bearings arranged outside of the wet area and therefore no corrosion.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

The BRÜCKNER hotflue is the heart of a continuous dyeing range and depending on the customers’ requirements it can be supplied with oil or gas heating. Due to the intelligent drive concept and a sophisticated air flow control an exact shade homogeneity is achieved across the length and the width of the fabric. Tailing and migrations are prevented and the dyeing results are 100% reproducible. This line is appropriate for all woven fabrics, particularly shirting and trouser fabric as well as home textiles such as bed linen. Benefits are among others best dye uniformity over the complete length and width of the fabric, no tailing, no migration, creasefree production, 100% reproducible dyeing results, minimum consumption of thermal and electrical energy, tailormade solutions for a maximum productivity even with small quantities, easy access for cleaning and maintenance due to large doors.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Our heatrecovery systems heat fresh air with the thermal energy of exhaust air and can be placed directly on top of a stenter frame. This system can also be retrofitted for older dryers. The benefits are high energy savings which allow payback periods of less than two years, depending on the layout and process, highly efficient platetype heat exchangers with nonstick coating, optimum ease of maintenance by removable drawersized heat exchanger modules, external cleaning of the heatexchangers in a hot water bath with ultrasonic cleaning equipment, high power density, higher than with usual tubetype heatexchangers.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

The exhaust air scrubber is used to clean hot or cooled exhaust air. It provides also for effective exhaust air cooling in widely selfcleaning washing zones, robust execution in stainless steel with compact dimensions. Benefits of this system are low operating costs, low maintenance, high operational reliability, operation with low quantity of waste water is possible.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

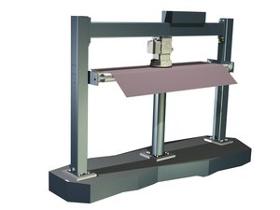

Our coating line concepts stand for maximum production output, low energy consumption and highest precision regarding temperature distribution, air circulation and coating application. We can offer many different coating application units, such as combined floating knife/ cylinder coating head, knifeonrubberblanket coating unit, magnet roll coating unit, paste dot or screen coating unit, powder scatter coating assembly, kissroll unit, impregnation bath, reverseroll coating unit and vertical floating knife coater. Our lines are used for coating many kind of end products, such as airbags, automotive interior, truck tarpaulin, architectural fabric, protective clothing, emery cloth, paragliders, awning cloth, billboards and many others.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Our ovens and line concepts for bonding and finishing of nonwovens stand for maximum production output, low energy consumption and highest precision regarding temperature distribution, air circulation and coating application. We can offer different application systems such like foam impregnation units, padders, spray cabinets, powder scattering units, coating heads and many others. In addition, we can offer complete lines like airthrough doublebelt thermofusion ovens, airthrough dryers for lightweight nonwovens, airthrough dryers for high speed spunlace lines for wipes or wetlaid nonwovens. Our customers are active in the fields of hygienics & medicine, construction & geotextiles, clothing & comfort, cleaning & care, automotive & transport, filtration and many more.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

We can offer finishing lines for glass fabric with extremely light surface weights for the production of circuit boards including highttemperature treatment up to 450°C, finishing lines for woven glass fabric for the production of glass wall paper and for the construction of reinforcement and grinding disks. We also can supply modules such as unwinding units, heating presses, fabric accumulators, drying and heat treatment units, traction units, stretching units, selvedge gumming and cutting units and batchers used as individual units.

Request for a quoteManufacturer/ Producer

Benzstr. 8-10

71229 Leonberg - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

BESER KIMYA SAN. VE TIC. LTD.STI.

Turkey

Product prepared with 8 – 10 % emulsifier and mineral base oil gives milky oil in water emulsions for textile fiber processing. Used for textile oil preparation for spinning, synthetic and wool fiber blending, cone transferring, kamgarn and streighgarn spinning operations Nonyl Phenol free nonionic type emulsifier package gives highly hard water resistant stable emulsions up to 100 DH Emulsifies easily and gives high degree of lubrication and washability. Eliminates static electric deposition during spinning

Request for a quote

MAHLO GMBH & CO. KG

Germany

Compressed air blade To monitor the progress of certain processes, there is no alternative but to take frequent samples at the machine itself. This is normally possible only while the product is either moving slowly or stopped, and often results in complicated work-arounds to enable continual production (continuously running winders, etc.). The Samplecut FSC is the solution to the problem. The tried and tested sample cutter Samplecut FSC takes samples from fast running product.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Keeps web safely on track Drifting of the product web lateral to the running direction of product is unavoidable in some stages of textile finishing. The Ceremat system brings the product back on the right path. Applicationspecific variants are available.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Control room application mPilot is a control room application for Mahlo equipment. The software allows the user to configure up to ten Mahlo devices with one control centre. Individually selected data of several devices are clearly arranged. The innovative control tool supports production and shift managers in handling their daily business as efficiently as possible. Key elements Display of running processes of up to ten Mahlo machines Job control (configure jobs and recipes) Configuration of product lines and machines Alarm management (current and historical warnings) Various communication protocols (OPC UA, OPC DA, Modbus TCP, Profibus, Profinet, Ethernet/IP) Start of predefined jobs (only with mCockpit)

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free