- europages

- >

- Sensors

- >

- QUELLTECH GMBH

- >

- Detection of Surface Defects with Laser Triangulation

Detection of Surface Defects with Laser Triangulation

Detect defects on the roll surface at an early stage

Description

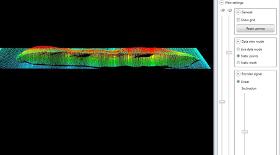

Defects to be examined in this application are very small, their size is often lower than 0.5 mm – hard to discover by human eye. Rework in the course of the production of the final product however, proves to be complicated and expensive. Large rolls with a diameter of 2 m and a length of 10 m are very difficult to remove and to reinstall. In order to avoid corresponding inconveniencies, it is essential to support the manufacturing process of the rolls themselves by a reliable quality control in the form of an automated final inspection.As the Quelltech Q6 laser scanner features an extremely precise resolution of 4096 Pixels/Profile at a high scan rate, this model proved to be able to meet the requirements and was mounted onto the positioning stage of the grinding machine. Furthermore, an industrial measurement computer was added, used for the analysis software of the point cloud. On the basis of this configuration, the entire roll surface could be recorded on a helical path.

- Sensors

- Surface defects detection

- Laser Triangulation

- Machine vision system

Product characteristics

- Country of origin:

- Germany

- Resolution:

- 4096 Pixels/Profil

- Machine Vision System

- Turnkey

Similar products from QUELLTECH GMBH

QUELLTECH GMBH

Germany

Laser sensor Q4 – with a small form factor – Q4 for standard 2D / 3D measuring applications: Low sensitivity against influences of secondary light Measuring ranges from 5 mm to 1000 mm Laser wave lengths starting from UV via blue, red and green through to IR Average measuring speed up to 350 Hz frame The Q4 laser sensor has been designed to meet the requirements of standard measuring applications. Thanks to its increased flexibility, it can be used for several tasks also in complex projects. The dimensions of the ultra-compact version amount to only 86x40x25, at a weight of 140 g. Protective panes and cooling modules are available as an option. The Q4 laser sensor model enables users to obtain stable measuring results also on difficult surfaces, whether mirroring or transparent. The QS-View Standard Software comprises a comprehensive selection of application modules, to be invoked at once without previous programming steps. Customized adaptations are possible any time.

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quote

QUELLTECH GMBH

Germany

The new QuellTech Q5 Laser Scanner Series combines the advantages of small form factors with both high resolution and scan rate. The sensor disposes of different set-up possibilities with respect to the analysis algorithm. Measurement results are delivered via Ethernet, calibrated in the X / Z plane. Special adjustable algorithms can be selected, extremely useful particularly also for optically most demanding surfaces. Time-consuming calibration tasks for the user are no more required, as the calibration routine runs on board. High Scan Rate with up to 14,000 Profiles per Second Due to an appropriate limitation of the image range (AOI) in X and Z direction, the scan rate could considerably be increased. High resolution and detection frequency with up to 14.000 profiles and 28 Mio. points per second •X measuring range from 10 to 1022 mm •Z measuring range (height) from 5 to 878 mm •Laser wave length blue 405/450nm, red 650nm

Request for a quote

QUELLTECH GMBH

Germany

The QS View software package is intended for dimensional control in 2D or 3D QS-View 2D / 3D software for all measuring tasks 3D representation of an irregular body for determination of volume and weight. With the 2D / 3D software a wide variety of parameters can be processed and displayed, e.g. length, width, angle height, gap, presence, volume (resp. weight), seam geometry (height, width), gap dimensions. Due to the modular structure of the software, customized specialties can be added any time. Each module delivers the results to an individual output module. The universal SPC interface allows simple connection to S7 controllers via Ethernet. 2D / 3D software developer kits are available for integrators with corresponding knowhow.

Request for a quote