EUROBALT ENGINEERING OÜ - hydraulic cylinders, hydraulic pipes, supplying powder metallurgy, die casting parts

Estonia

Manufacturer/ Producer

EUROBALT ENGINEERING OÜ

Estonia

Length of the cylinder retracted / extended / piston stroke: 550 / 2400 / 1200 mm; Weight: 31,20 kg; Working/Test pressure: 16 MPa / 20 MPa; Diameter of the cylinder: 128 mm; Oil feed connector: G1/2" male thread; Required volume of oil: 5,7 L;

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Length of the cylinder retracted / extended / piston stroke: 390 / 1300 / 910 mm; Weight: 20,2 kg; Working/Test pressure: 16 MPa / 20 MPa; Outer diameter of the cylinder: 110 mm; Hydraulic connector: G1/2"; Volume of oil required: 3,5 L;

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Length of the cylinder retracted / extended / piston stroke: 366,5 / 1166,5 / 800mm; Weight: 20,72 kg; Working/Test pressure: 16 MPa / 20 MPa; Outer diameter of the cylinder: 108 mm; Hydraulic connector: G1/2"5; Volume of oil required: 3 L;

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Length of the cylinder retracted / extended / piston stroke : 396,5 / 1096 / 700mm; Weight: 18,26 kg; Working/Test pressure: 18 MPa / 22 MPa; Diameter of the cylinder: 95 mm; Output to connectors: M22x1.5; Volume of oil required: 2,5 L;

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Length of the cylinder retracted / extended / piston stroke : 425 / 1010 / 585 mm; Weight: 18,76 kg; Working/Test pressure: 16 MPa / 20 MPa; Oil feed connector: M22*1.5 internal thread; External width of the cylinder: 110 mm; Required volume of oil: 3 L;

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Currently, production of the parts from mixed metallic powders is slowly displacing traditional casting and stamping. It is happening because this method is different with its speed and cost efficiency. Wastes from the metal-parts production can be used to produce powders. Parts, produced by this method, have high durability and wear-resistance. Sintering allows to receive parts with precise geometric forms. Parts don’t require further machining. Technology of production of sintering suggests putting metal powders into special forms. They are thermal treated in the gas environment, that allows to increase plasticity of material and also add special polymers. Then, parts are being pressed, rolled and formed. During those processes, parts of the metal powders are strongly melted with each other, creating a monolith mass. In order to provide parts with hardness and wear-resistance, they are being thermal treated in special furnaces. More info https://eurobalt.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

The production of cnc turning parts is a quite difficult process that requires a lot of attention, excellent machinery and experienced specialists. Our customers set high requirements for the production of their metal parts. Today, various metal parts almost can’t be produced without applying this or that type of additional machining process.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

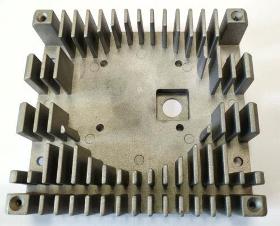

Metal die casting – is a production technology of castings, in which the alloy under pressure up to 700 MPa quickly fills the mold. Products made in this way can be of different sizes and have weigh up to several kilograms. As a basic raw material normally are used following: non-ferrous metals — copper, aluminum, and their alloys. Die casting makes it possible to obtain high-precision products (along with such technology as powder metallurgy, which allows to obtain sintered metal parts that are particularly hard and wear-resistant). Our company offers the manufacture of parts for LED lighting and other high quality castings. One of the main advantages of die casting is the resistance of finished products to corrosion. The fact is that in the process of their manufacture a strong surface crust is formed, which has a high density and low moisture permeability.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

In some cases, metal powders can be easily made of separate metal parts. Powders are used to create floor and building structures, as well as for surfacing. Their application is possible in engineering, nanotechnology, metallurgy, aviation and industrial industry. At our site, you can order production of sintered powder parts. In this article, you will learn about the basic methods of obtaining metal powders. Parts made of sintered metal. Methods for obtaining metal powders are divided into two types: mechanical and physico-chemical. Mechanical methods are more common way to produce metal powders. For this purpose, special devices are used. It is especially advantageous to use this method in the manufacture of powders of beryllium, antimony or chromium.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

We provide the die casting manufacturing with a wide range of advantages for our clients: Excellent dimensional accuracy Smooth cast surfaces Thinner walls can be cast as compared to sand and permanent mold casting Fast production cycle times Reduces or eliminates secondary machining operations Rapid production rates Casting of low fluidity metals Long tool life, especially for zinc and magnesium Our production line provides manufacturing casted parts like Transmission gearbox housing, LED Housing, Oil pans, Engine blocks, Light boxes and other custom parts according to your drawings.

Request for a quoteManufacturer/ Producer

Valge 13

11415 Tallinn - Estonia