GAICTECH - The canning machinery company

Spain

Manufacturer/ Producer

GAICTECH

Spain

The Tunidae Classification Line is a sophisticated system designed for the automatic calibration of tunas, leveraging both size and weight metrics to ensure the highest yield during the cooking process and facilitate selective storage. This line is capable of handling up to 50000 kg/hour for fish up to 15 kgs/unit with a single line, and offers the option for expanded production through multiple parallel lines for outline-based classification. Weight-based classification capacities are tailored according to the range of sizes to be classified, ensuring versatility and adaptability to specific production requirements. Constructed from durable and hygienic stainless steel AISI 316-304, the system incorporates advanced features such as the combination of outline and weight classification for large-scale productions with high accuracy. It also allows for the preliminary manual classification of species, or through machine vision cameras, to remove non-predominant species

Request for a quote

GAICTECH

Spain

The Tuna Fish Steam Cooker is expertly designed to refine the production process for tuna, focusing on increasing total fish yield through precise thermal gradient control and moisture content preservation. This ensures the fish remains moist, facilitating easier cleaning post-cooking. Tailored for flexibility, it offers adaptations for client-specific trolleys and the option for cooking without vacuum, enhancing its utility in diverse processing environments. Remote support capabilities allow for diagnostics and adjustments via PC and Ethernet, ensuring seamless operation and troubleshooting. Constructed from high-quality stainless steel AISI 304 L, the cooker is built for durability and hygiene compliance. Key features include a fully automatic cooking cycle, options for time or temperature-driven cooking directly in the fish's bone, and advanced process control via the latest generation PLC with exclusive tuna cooking programming. Temperature monitoring through thermocouple

Request for a quote

GAICTECH

Spain

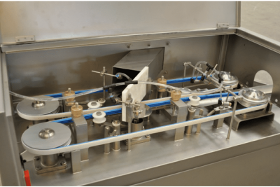

Tailored to meet the specific production needs of clients, the Tuna Cooking Blancher is an advanced machine designed for the optimal cooking of tuna. It features a lid closure system operated by a hydraulic cylinder, ensuring a watertight seal with a water gutter that prevents steam from escaping, except through a designated duct at the rear. This design not only prevents steam buildup in the workspace but also reduces cooking time by efficiently managing steam release. Fat collection is ingeniously handled at the back of the blancher, with front-located water diffusers activated during fish removal to drag the fat layer away, ensuring it doesn't impregnate the fish. Temperature control is achieved via a strategically placed thermocouple, with steam flow managed by electrovalves. Additionally, cooking time is meticulously controlled by a programmer, alerting operators with both visual and auditory signals when the process is complete. The interface includes a touch screen

Request for a quote

GAICTECH

Spain

The Pin-Bone Remover Machine is an innovative solution designed to efficiently remove bones from various types of fish and the shell from crustaceans such as shrimps, prawns, or king prawns, whether raw or cooked. This versatility ensures the production of an excellent product for a wide range of applications. The machine offers optional features like constant and controlled feeding through a helicoid mounted on the reception hopper and customizable diameters of the holes in the drum (between 1.5 and 8 mm), depending on the desired product outcome. Constructed from durable stainless steel AISI 304, it meets the highest standards of hygiene and longevity. In the canning industry, particularly for tuna, it's used to separate bones from flakes generated during the cleaning process, with a perforated drum that's easy to assemble or disassemble. The diameter of the holes can be adjusted to balance production and flake quality, with smaller diameters

Request for a quote

GAICTECH

Spain

This Loin-Mincing Machine is engineered to precisely cut or mince tuna loins to predetermined lengths, facilitating efficient preparation for bagging or other packaging formats. Crafted from durable and hygienic stainless steel AISI 316-304, it ensures longevity and adherence to food safety standards. The machine features a conveyor system equipped with a canvas belt designed for food purposes, moving tuna loins smoothly to the cutting area. A blade with vertical movement performs the cutting, offering the option to adjust the length of the cut to meet specific requirements. Digital indicators provide precise control over the cut length, ensuring uniformity across all products. Safety is a priority, with doors equipped with electrical interlocks to protect operators in case of accidental opening during the cutting process. This loin-mincing machine represents

Request for a quote

GAICTECH

Spain

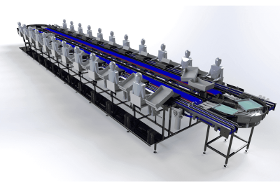

These Cleaning Lines are meticulously designed to enable operators to achieve high productivity levels and optimum performance in tuna processing. Tailored to meet the specific needs of each client, these lines offer optional features such as different designs based on available space, the choice between a closed circuit for unclean fish and clean loins (recommended) or a straight-line design, and the possibility of individual tables for each operator. Dimensions are adapted to client production requirements, and the construction is made of durable and hygienic stainless steel AISI 316-304. The lines facilitate the entry and exit of boxes with clean or unclean fish, either automatically or manually, and feature transport of unclean fish, clean loins, and waste in independent, differentiated areas. Production control options include the ability to monitor each operator in real time, with total and per operator yields and traceability. Custom programs can be tailored to client

Request for a quote

GAICTECH

Spain

Designed for robust industrial cutting tasks, this Chop Saw features a cutting power of 6 CV at 1,800 revolutions per minute, ensuring efficient and precise cuts across various materials. Its design is shielded for direct washing with high-pressure water, enhancing cleanliness and maintenance ease. The saw offers manual height adjustment of the protection guide and pulleys with a 400 mm diameter made from stainless steel, ensuring durability. With a saw blade width of 20 mm and manual tensioning, as well as an adjustable steering wheels tilt, it provides versatility for different cutting needs. The maximum cutting dimensions include a height of 600 mm and a width of 800 mm, catering to large materials. The working table measures approximately 1,000x900 mm, offering ample space for various projects. It accommodates both right-hand and left-hand cutting, with a special guide

Request for a quote

GAICTECH

Spain

The Bagging Machine for Tuna Loins is designed for the semi-automatic insertion of cooked and clean tuna loins into bags, streamlining the preparation process for subsequent freezing. Capable of handling 7 kg bags at a rate of up to 8 bags per minute and 10 kg bags at up to 6 bags per minute, this machine requires 4-5 operators for optimal performance. Constructed from durable and hygienic stainless steel AISI 316-304, it ensures longevity and compliance with food safety standards. The volumetric filling system guarantees great uniformity in the volume of bags filled, without producing pieces or flakes, enhancing product quality. Its design facilitates easy cleaning, as it can be fully disassembled, allowing all parts to be accessible. Additionally, the machine offers the flexibility to work with several bag sizes by simply modifying the length, accommodating various packaging needs. This bagging machine represents a significant efficiency

Request for a quote

GAICTECH

Spain

The Sardine Packing Line is expertly crafted to enhance the manual packaging process for pelagic species such as sardines, anchovies, mackerel, and horse mackerel, ensuring efficiency and optimal presentation. Constructed from high-quality stainless steel AISI 316-304, it offers durability and meets stringent hygiene standards. Tailored to the specific production requirements and packaging formats demanded by the market, this line is designed with ergonomics in mind, facilitating ease of use and minimizing operator fatigue. It features a special design for rectangular formats like ¼ Club, Dingley, or similar, allowing operators to achieve higher yields through dynamic packaging methods that result in an excellent presentation of the fish. The line also includes options for directing containers to grills or cookers and is equipped for integration with an automatic feeder of empty containers, further streamlining the packaging process.

Request for a quote

GAICTECH

Spain

The Sardine Gutting Machine is meticulously designed for the specific task of gutting sardines, ensuring high efficiency and precision in seafood processing. Capable of handling up to 300 fish per minute, this machine features a transport system with specially designed belts to smoothly drag the fish through the gutting process. It performs both the trunk cut by the front and the belly cut by the side, utilizing two circular blades for the gutting system. Constructed from durable stainless steel AISI 316-304, the machine combines robustness with ease of maintenance. Its simple operation is complemented by a flip-top lid offering easy access to internal mechanisms, equipped with an electrical interlock for enhanced safety during maintenance or accidental openings. This gutting machine can seamlessly connect with any cutting-gutting machine on the market, offering versatility

Request for a quoteManufacturer/ Producer

Rúa dos Padrons, 8

Polígono Empresarial Porto do Molle Nigrán

36350 Nigrán-Pontevedra - Spain