- europages

- >

- Industrial robots

- >

- GIZELIS ROBOTICS

- >

- products

GIZELIS ROBOTICS

Greece

Manufacturer/ Producer

GIZELIS ROBOTICS

Greece

As per robotic applications for welding, there are specific welding machines (MIG/MAG, TIG) that feature real-time machine-robot communication. The robot may change its parameters or select one of the machine’s preset programs. There are also the automatic wire feeder located on the robot for its proper feeding, the welding pincer and the automatic pincer cleaner that guarantees consistent welding quality even after many hours of operation. One additional component used is a shock sensor, which ensures that the robot will stop in case of collision. Another feature of these robots is that they can control the welding pathway by means of special sensors. Robots may also manipulate external axes and expand their work envelope, and thus facilitate welding in difficult parts of pieces. Also, by means of a positioner, the system acquires increased flexibility and registers huge increase in productivity.

Request for a quote

GIZELIS ROBOTICS

Greece

All industrial units feature standardized and repetitive, e.g. press-brakes, plastic or metal moulding, product re-orientation, CNC feeding etc. Industrial robots are extensively used in these applications as they offer much higher productivity. Precision in product placing is top-notch and provides for end-product consistency, whereas machine downtimes are eliminated. Thanks to their manufacturing, robots may operate even in clean rooms and -contrary to manpower- they may handle products without running the risk of bacterial infection, thus reducing production costs even more (no need for sterilization ). Robotic flexibility allows for no limitations in the tasks undertaken and enables cooperation with all machinery of an industrial unit.

Request for a quote

GIZELIS ROBOTICS

Greece

Regardless of the material to be handled (sack, carton box, tin or bottle), this robotic arm picks-and-places with utmost precision (≤0,25mm). It may also handle multiple product lines concurrently, as well as different types of products by means of special grippers, thus further increasing the degree of system flexibility. A comprehensive palletizing line includes, apart from the robot and gripper set, product conveyor belts, automatic pallet feeder for attaining higher speeds, ready pallet roller conveyors, pallet transport wagon for large areas, and automatic pallet wrapper with stretch film, automatic strapping machine, and safety fence for personnel safety.

Request for a quote

GIZELIS ROBOTICS

Greece

An IP 67 rating stands for full protection against dust ingress and protected operation against immersion and water penetration (designated by the second digit). Moreover, robotic systems feature smooth finishing, so there are no areas for bacteria build-up, and integrated through-the-arm cabling for problem-free transfer of signals and air, as well as easy, risk-free cleaning with any type of cleaners. Moreover, a food industry-specific grease is used in their spindle reducers. Robotic systems’ main advantage lies in the fact that they may work together with any packaging machinery (carton sealer, film etc) to offer increased operating flexibility to any application. Typically, packaging robots are followed by palletizing robots, however if line speeds are low, packaging robots may also undertake palletizing for additional production cost savings. For all the above reasons, it is easy to understand why all food and pharmaceutical companies apply robots in their production lines.

Request for a quote

GIZELIS ROBOTICS

Greece

Assembling various components amongst them is a complicated procedure for automation and it is usually delivered by humans. Thanks to the industrial revolution and fast technological development, robotic arms have stepped in and already been established as an essential part of the process given their advantages. There are many types of robotic systems that are ideal for assembling and selecting one is determined by system speed, component weight and maximum operating radius.

Request for a quote

GIZELIS ROBOTICS

Greece

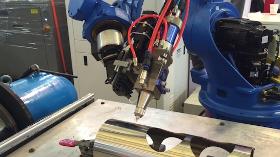

Cutting is a process that demands extreme precision. In particular when it comes to a 3D cut, extreme flexibility is required apart from precision. Robotic arms provide such flexibility since they move no matter what their tool’s orientation is. A cutting tool is mounted on their fixture (LASER, PLASMA, WATERJET, ROUTER etc) and the robot follows the cutting path and delivers remarkable results. For easy cutting robot programming, there is dedicated software which generates automatically the robot's source code once the 3D sketch including cutting points is entered. Moreover, the robot may be equipped with various sensors in order to keep the proper distance while cutting, as well as to identify differences between an existing piece and the sketch and to calculate the optimum solution based on tolerances.

Request for a quote

GIZELIS ROBOTICS

Greece

Press-braking is also a popular application for robotic arms. By automating rolling procedures, we attain consistency of end products and provide safety to our work force since many accidents at work have occurred during this application. An important role is played by the gripper, which is mounted on the robot's extremity (flange) and takes on holding the sheets throughout forming. Holding is implemented with under-pressure (vacuum) by means of cup or magnets when sheets have large holes on them. Grippers require special design in order to handle application-specific sheets and not cause problems to the press-brake or the robot during operation.

Request for a quote

GIZELIS ROBOTICS

Greece

Robotic systems assist in such applications thanks to their particularly enabling features. Typical grinding applications include a closed robotic cell to avoid particle dispersion in the surrounding area. A head-bearing robot is located inside as well as various other grinding machines. The robot picks the piece from the feeding area, drives it with precision through all processing stages and places it at the discharge area before it starts all over again by picking the next piece. Depending on the product, a suction system is put in place to keep the robotic cell clean. Robotic grinding is the only option for all related industries since production time is greatly decreased, maximum degree of safety is achieved and, most significantly, it offers flawless quality and consistency to end products. Only companies using robotic systems stand out from the competition, as they can produce optimum products at the lowest possible production cost.

Request for a quote

GIZELIS ROBOTICS

Greece

Painting or coating production tasks are exactly what robots are designed for. Robots also spray on solvent-based paints with or without high voltage, always achieving the same results. In the automated cell it is easier to maintain a consistent temperature and humidity, resulting in reproducible quality. Although a MOTOMAN robotic system is extremely fast, its high precision and well coordinated movements along the path save a considerable amount of time and reduce waste. The paint coating is applied consistently at maximum speed, with guaranteed perfect results. The MOTOMAN EPX series offers a range of painting robots that are perfectly tailored to customer requirements and provide top quality results. Benefits: - Improved and consistent quality - Cost saving by using less paint - Reduced dependence on manual labour - Improved working environment

Request for a quote

GIZELIS ROBOTICS

Greece

Gizelis Robotics provides turn-key solutions for machining with robots for all kind of materials like wood, stone, marble, alumium, steel etc. The robot cell consists of: Robot Spindle Robot CNC CAM Software Machining table Automatic tool change Safety fence There is also the possibility for costumers to bring their parts and make them a live demo. Robot CNC CAM software lets you program robots with external axes such as rotary tables and linear tracks as easily as you could program a 5-axis NC machine. Working closely with the highly skilled integrator Gizelis Robotics opened up new opportunities for testing the software which guarantees fast, accurate and easy multi-axis programming for robots.

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

TURKISH MANUFACTURERS UNION

Turkey

ERCOM KOMPRESOR Produces many types of screw air compressors. you can reach directly through 00905301372145

Request for a quote

BVS ELECTRONICS GMBH

Germany

CNC systems, industrial robots and accessories for every requirement Products manufactured by Fanuc stand for the highest quality and meet the user's specific requirements. We have particularly specialised in CNC systems, industrial robot components, drives and motors for the globally leading company that specialises in the factory automation sector. With our extensive portfolio consisting of repair, sale and service we will be happy to help you at any time – regardless of whether you have got a faulty FANUC module or quickly require a replacement or new part. With over 40,000 FANUC assemblies, we have a suitable solution for every requirement.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free