GSW SCHWABE AG - Sheet metal fans since 1963

Germany

Manufacturer/ Producer

GSW SCHWABE AG

Germany

Safe upending of coils (90°) Body design in solid welding construction with reinforced base with no pit or floor anchoring needed Body made of strong steel plates Base with large integrated floor plate and attached box construction to protect drive components Tilting unit with neatly welded half shell attachments and two reinforced coil tables welded at 90 degrees to provide safe material seating Bedding via four pressureresistant and fully enclosed bearings with lifetime lubrication Tilting shaft of highquality ductile steel with fully enclosed bearings Tilting drive via threephase motor and triplex type Highstrength chain Tilting function via initiator with arbitrary adjustable tilting point Electrical conrol in switch box with leftright selector switches and estop

Request for a quote

GSW SCHWABE AG

Germany

Upenders are designed to safely tilt big and heavy coils – either from horizontal into vertical or reversed. This fast and easy coil handling solution gets rid of “adventurous” tilting methods that often will endanger the operator. Chains and other lifting aids which damage the coil rims become obsolete. Upenders allow 90 degrees tilting of coils; Combination machines will also rotate 180 degrees. Both can handle up to 25 tons.

Request for a quote

GSW SCHWABE AG

Germany

shock dampening for low operating noise levels absolutely sturdy and warpresistant body design with heavy doublepost guides to smoothly cut even toughest materials with adjustable blade clearance for a most precise cut at any thickness very precise blades made of special steel high operating safety through material guide at entrance and protective cover springactuated hold down clamp (from 250 mm stock width) top/bottom dead center control to monitor blade position counter control mounting bracket hydraulic power units in different sizes electrical control

Request for a quote

GSW SCHWABE AG

Germany

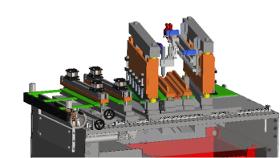

Our sequence-controlled system includes a precision welding head and precise cutting and positioning devices. The two integrated Hydraulic Shears and the strip clamps can be moved so that the leading and trailing strip ends can be fitted precisely. For those who like it less automated but more cost-effective, we have developed a simpler technology – using just one Hydraulic Shear and fixed clamps. The strip ends are positioned manually here – this is supported by an easily accessible hand lever to individually activate the pneumatic clamps. A double edge guide with vertical rollers centers the new strip and can be adjusted also decentral for alignment. The actual welding process is taken over by the operator himself.

Request for a quote

GSW SCHWABE AG

Germany

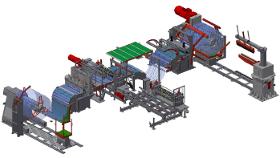

Cut-To-Length Lines are core competence at GSW. They belong to the family of Cutting Lines and are designed to process diverse materials out of steel, non-ferrous metals or aluminum and precisely cut a coil into sections of equal length (which is where the name comes from). Starting with narrow slit strip and finishing somewhere beyond 2000mm width – our Cut-To-Length Lines always know how to shine in this process.

Request for a quote

GSW SCHWABE AG

Germany

Also Slitting Lines do of course belong to the family of Cutting Lines. They are suitable especially for such customers who have to control a large portfolio of coil widths within their production. And if you build quality products you need quality even in your primary material. Finding it requires a good Steel Service Center but can be costly and unavailable at time of need. So why not cut your own coils? Our Slitting Lines are optimized for smaller batches and provide flexibility supporting your deadlines.

Request for a quote

GSW SCHWABE AG

Germany

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

GSW SCHWABE AG

Germany

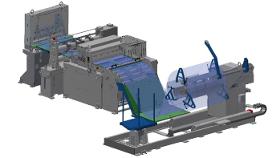

With Conventional Feed Lines, the focus lies on speed and material surface. That’s why Conventional Feed Lines are equipped with a Coil Reel for pull-off, a Straightener with variable frequency drive a coil loop and a Servo Roll Feed: the loop uncouples the more inert straightening process from the highly dynamic indexing process and thus allows for high line speeds and preservation of the material surface. Since productivity and capacity demands can vary significantly, we have created different control concepts: while small Feed Lines work with a simple pneumatic drag brake at the Coil Reel and an ultrasonic sensor to control the Straightener speed, the large Feed Lines get fully synchronized controls with motor-limited Coil Reels and a smart loop, creating a steady average speed of the whole line. This allows smooth pull-off of high coil weights while the loop remains very calm – in addition, the Servo Roll Feed can work with full dynamics, even at long indexing progressions.

Request for a quote