- europages

- >

- Heat treatment of steels and metals

- >

- IONITECH LTD.

IONITECH LTD.

Bulgaria

Manufacturer/ Producer

IONITECH LTD.

Bulgaria

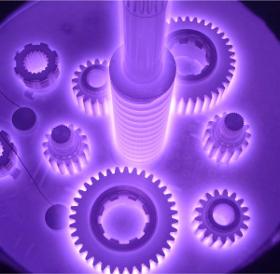

In the Hot-Wall type plasma nitriding installations, the heating of the parts in the vacuum chamber is done by both heaters and pulsed plasma. This type of installations are especially suitable for nitriding different shaped and sized parts in one batch. The main advantages of this type of equipment are: - The installations fully comply with the AEROSPACE MATERIAL SPECIFICATION; AMS 2759/8A; Can plasma nitride parts for the aerospace industries; Absolute temperature uniformity in all parts; The chambers could be equipped with their own lifting mechanism; No water cooling of the vacuum chamber;

Request for a quote

IONITECH LTD.

Bulgaria

The heating of the parts, in a Cold-Wall plasma nitriding installation, is carried out only by pulsed plasma created in the vacuum chamber. This type of plasma nitriding equipment is especially suitable for nitriding similar in shape and size batches of parts. The main advantages of this type of equipment are: Lower cost of the equipment; Easy maintenance; Lower consumption of electrical energy;

Request for a quote

IONITECH LTD.

Bulgaria

Ionitech Ltd. has its own plasma nitriding units and provides services of plasma nitriding, plasma nitrocarburising and post-oxidation using our more than 40 years of experience to achieve the best results. Upon client's desire we make metallographic test reports containing information about the process, the surface hardness of the steel, microhardness in depth (diffusion depth) and metallographic studies of the nitrided layer. Plasma Nitriding is also capable of treating parts of Stainless Steel without the necessity of a predepassivation process. The treatment could also be carried out so that it could preserve the corrosion resistance of the steel. Post-Oxidation is done if there is a requirement to increase even further the corrosion resistance of the parts or tools.

Request for a quoteIonitech Ltd. is a manufacturer of Plasma Nitriding Equipment. For the last 40 years we shared our Know-How and expertise in more than 20 countries on 4 continents. Our primary goal is to bring worldwide industry forward by providing the most reliable equipment and the best technology and results to our partners. Ionitech Ltd. offers the biggest variety of plasma nitriding equipment in the world. Depending on the clients' requirments, the furnaces could be a hot-wall or a cold-wall type and vary in size and power. They are fully designed and produced by the company's engineers. Ionitech Ltd. works daily to develope the plasma nitriding technology. Ionitech Ltd. also has it's own plasma nitriding units and provides services of plasma nitriding, plasma nitrocarburising and post-oxidation using our experience to achieve the best results. On client's desire we make metallographic test reports containing information about the process, the surface hardness of the steel and metallographic studies of the nitrided layer. Plasma nitriding and plasma nitrocarburising are used to improve the surface hardness, wear resistance, fatigue life, corrosion resistance of parts made of steel, cast iron, titanium and aluminum alloys, sintered materials, etc.

Website

Company info

Key figures

-

- Company headcount

- 11 – 50

Organisation

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Delivery areas

Activities of IONITECH LTD.

- Heat treatment of steels and metals

- Plasma Ion Nitriding

- manufacturer

- stainless steel

- steels

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

HFP BANDSTAHL GMBH & CO KG

Germany

This material group stands for breaking strength, service life and wear resistance. Due to these properties, quenched and tempered steel is always used where high strength, yield strength and high toughness are required for highly stressed machine parts. C 22 E, C35 E, C 45 E/➔ according to DIN EN 10132 - 3 Depending on the customer's requirements, we supply treatment states from soft annealed to high cold solidified.

Request for a quote

M.E.G.A. SPA

Italy

M.E.G.A.’s forging and heattreatment division is capable of forging fittings (in a closed die) up to 4” 16 kg. The heat treatment furnaces and tanks are all certified to Norsok M650 and ASTM A991 standards and can treat any product that M.E.G.A. produces (large and small forgings, pipes and any other type of part).

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

We process the following materials: ■ chrome-nickel steel ■ various types of steel ■ non-ferrous metals ■ various aluminium alloys steel processing, stainless steel, machine engineering, tool engineering, metal processing, sheet steel processing, material 16 Mo3, Hardox, 1.4301, 1.4571, 1.4404, S355, S235, metal products, steel products, supplier construction machinery, power station, energy station, offshore equipment, pipes, steel halls, metal construction, profiles, handrails, balconies, stairs, roofing, pallet warehouse, pallet inverters, scrap conveyors, transport racks, special frames, devices, die blocks, barrel press, fork shoes, fork extensions, industrial gates, fences, customized constructions, industrial service, furnaces, playgrounds, sports fields, cladding, casing, housing, covers, noise-protection cabins, machine frames, large milled parts, conveyor technology, conveyor line, plunge pools, tank barrels and much more

Request for a quote

ESTIMET SP Z O.O.

Poland

In our production plant we have a number of machines and equipment for surface treatment. The "before" and "after" effects are visible in the photos.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free