LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN - LIPP System - UNIQUE.WORLDWIDE

Germany

Manufacturer/ Producer

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

MADE FROM VERINOX STAINLESS STEEL OR GALVANISED STEEL WITH VOLUMES RANGING FROM 40 M3 TO 10,000 M3 Both industry and communities require professional solutions for plant and tank construction and for the storage and treatment of liquids, as well as flexibility in terms of size, choice of material and equipment. When constructing liquid storage tanks, the selection of the best material is an important quality factor. Municipal/industrial waste water and sludge or certain processing, intermediate and end products from the chemical, pharmaceutical and food processing industries set high requirements regarding the tank material, for example. LIPP offers a variety of materials, ranging from galvanised steel through the combination material Verinox to high alloy stainless steels. APPLICATIONS Waste water tanks Sewage sludge tanks Process water tanks Storage tanks Firefighting water tanks Mixing and compensation tanks Buffer Tanks Stackable sludge tanks Storage containers

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

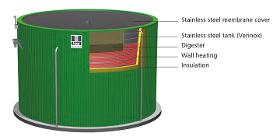

PATENTED DIGESTER WITH INTEGRATED GAS ACCUMULATOR LIPP KomBio Reactor for industry and local authorities The innovative and outstandingly economical solution for energy production at biogas plants and stabilisation of sewage sludge has been in use in many countries for over twenty years. Quick realisation, low investment costs, high operating safety and long service life are all characteristics that speak for themselves. The system is suitable for small and large plants and complies with industry standards. KEY BENEFITS Production of renewable energy and reduction of fossil CO2 emissions Low noise emissions Flexibility with regard to substrate composition Compact and space saving with minimal pipeline construction High functional safety Steel roof (can be insulated) to protect against the weather Individually customisable for intended application Good insulation reduces heating demand Patented stirring systems Fast construction with production on site Low investment costs

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Tank Accessories special attention is paid to ensure quality, safety, longevity and cost efficiency. Solid, well thoughtout finishing in every detail. Particular attention is paid to leaktightness. Openings or leadthroughs can also easily be made after attachment/installation. A broad range of technical tank accessories is available for all containers. Some are produced inhouse and some are purchased via partners or carefully selected suppliers with whom Lipp has established longterm relationships based on trust. Accessories tank bottom, tank insulation, pumping and stirring technology, overflow gutters, tank heating, steps, platforms, operating bridges, overpressure and underpressure protection devices, pipeline construction, sensors, etc.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Stainless steel digester with a digester chamber volume of 100 to 2500 m3 Integrated gas accumulator – fixed in gutter for high operating safety Optimised diameter to height ratio for optimum mixing and minimal stirring Low maintenance, external panel heating system Flexible stirring technology which can be adapted to the substrate and digester Stirring technology can be maintained without having to empty the tank

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Gas Accumulators were developed as a system for the nonpressurised storage of dry gas which has been used for over 300 projects worldwide over the past years or more. Sizes from 30 to 5000 m³ are available according to the gas yield in each case. The gas accumulator consists of two parts a bubbleshaped storage balloon and a steel container to protect the balloon against mechanical damage and the effects of weathering. Speciality Accurate level measure of stored gas. In biological processes, gas production is not continuous. That is why the utilisation of gas (e.g. in a combined heat and power plant) requires an accumulator in order to compensate for fluctuations during gas production and to bridge downtimes for plant repairs and maintenance. Besides high functional and operating safety, other important criteria for the construction and operation of gas tanks include the economic aspects of investment and maintenance costs.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The high functional safety, especially for heating and stirring technology, ensures a low demand for process energy and this is combined with the benefits of minimal maintenance requirements and a long service life.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The automated assembly technology in the LIPP Double Seam System enables the fast construction of stainless steel tanks, which in turn has a positive effect on investment costs. The benefit for you flexible construction technology with efficient production on site requiring minimal installation space and ensuring a short installation time. The smooth internal walls of the LIPP Digesters (largely without any internal attachments) ensure gentle, uniform mixing while keeping energy consumption low. The external heating system guarantees uniform temperature distribution in the digester. These mechanical and thermodynamic benefits with LIPP digesters mean short retention times.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

WITH DIGESTER CHAMBER VOLUMES RANGING FROM 200 M3 TO 5.000 M3 The LIPP Universal digester which unlike the KomBio reactor does not have an integrated gas accumulator, is used for larger plants for industry and municipalities. The biogas accumulated is either directed into a KomBio reactor combined with the Universal digester or into a separate gas accumulator. KEY BENEFITS Production of renewable energy and reduction of fossil CO2 emissions Low noise emissions Flexible substrate composition Customisable pumping and stirring technology High functional safety Effective insulation results in low heating requirement Quick construction thanks to on site production Low investment costs Low maintenance and durable Consistent quality worldwide PRODUCT SPECIFICATION MODULAR PLANT CONCEPT The LIPP Universal digester essentially consists of a (Verinox) stainless steel tank with a modular design. Panel heating and insulation are fitted on the outside and are easily accessible.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® offers a wide range of Roofs and Covers for covering liquid, solid or gaseous media. They can be tailored and adjusted to each application. They include both roofs developed by LIPP® and also solutions designed by our partners. There are also simple foil roofs to choose from for gas storage facilities as well as singleskin, doubleskin or double diaphragm roofs. The LIPP® stainless steel diaphragm roof also offers a particularly highquality solution for the storage of volatile or explosive substances while the versatile LIPP® segment roof completes the range of covers.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Stainless steel digester with a digester chamber volume of 200 to 5000 m3 External panel heating and insulation Optimised diameter to height ratio for optimum mixing and minimal stirring Flexible stirring technology which can be adapted to the substrate and digester Stirring technology can be maintained without having to empty the tank

Request for a quoteManufacturer/ Producer

Industriestrasse 27

73497 Tannhausen - Germany