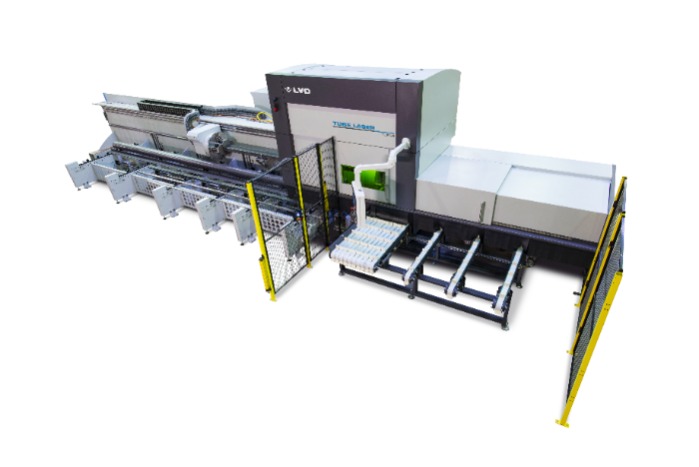

The TL 8525 is LVD’s next generation tube laser cutting machine. Designed from the ground up, it comes equipped with a number of high-performance features to optimize tube cutting for even the most complex of applications. Built for high productivity, the TL 8525 has a large 8500 mm infeed length and can process tubes up to 250 mm round or square with a maximum part length of 3000 mm. A 400 mm Z-axis permits the cutting of larger profiles. To provide versatility for the widest range of use, the TL 8525 is equipped with key features typically offered as options on comparable machines. Standard machine features include a 45-degree 3D tilt-axis cutting head for beveling, 6-position front loader, and a wide X-axis cutting head range of 1190 mm to maximize material usage. The TL 8525 has a compact footprint and offers the advantage of accessibility on all sides. Because loading/unloading is handled on one side, the machine can fit in a small space or against a wall.