- europages

- >

- Finished Metal Products

- >

- MR CO. LTD.

- >

- products

MR CO. LTD.

Ukraine

Manufacturer/ Producer

MR CO. LTD.

Ukraine

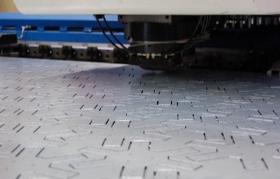

Laser cutting is a modern and efficient way to machine sheet metal, in which the cut is formed due to the impact of the high-energy light beam. The laser head moves along programmed lines and cuts through the material with high precision. The process is characterized by increased speed, cost efficiency and excellent productivity. CNC laser machines eliminate the human factor and allow us to cut completely identical workpieces with the required configuration with an accuracy of up to 0.05 mm, regardless of their number. Correct placement of elements minimizes loss of material.

Request for a quote

MR CO. LTD.

Ukraine

Hydroabrasive cutting of sheet materials. Does not cause changes in the processed material due to the absence of thermal influence. Maximum thickness of the workpiece: 150 mm. Processing area - 2000×3000 mm. Accuracy up to 0.1 mm (for a thickness of 40 mm).

Request for a quote

MR CO. LTD.

Ukraine

By the principle of operation, the coordinate punch press resembles an office paper puncher. The workpiece is pressed against the matrix. After that, a punching tool, the punch, strikes the workpiece with a force of up to 200 tons. In a fraction of a second, the punch and pressure ring return to their original position and the position-sensing mechanism moves the workpiece for the next strike. The capabilities of the equipment are not limited to the production of through-holes. Using punches of different sizes and shapes allows us to perform the most diverse tasks, such as countersinking, dimpling and forming. Modern coordinate punching machines are characterized by high productivity with moderate energy consumption.

Request for a quote

MR CO. LTD.

Ukraine

Sheet metal bending is one of the vital processes of metalworking. The sheet bending workshop of MR Ltd is equipped with the latest European equipment, which provides unsurpassed results. Thanks to CNC technology, the entire folding process, from programming and the tool setting to bending, is very productive. Our equipment and experience allow us to perform work of any complexity, from single orders to large-scale production.

Request for a quote

MR CO. LTD.

Ukraine

Milling is the process of machining metal with a specific cutting tool, a milling cutter. The milling cutter removes excess material from the workpiece to produce an element of a given shape. Unlike turning, in milling, the workpiece moves forward while the milling cutter rotates. By milling processing, you can obtain a part with a complex shape and geometry from a workpiece. The milling machine is primarily used for demanding tasks such as gear cutting. Our machining workshop is equipped with the most advanced high-tech CNC equipment. We offer our customers full-cycle material processing services, from designing to the protective coating.

Request for a quote

MR CO. LTD.

Ukraine

Argon welding is a popular name among people for welding technology, in which welding is performed in a shielding gas environment, most often argon. The gas prevents the metal under welding from coming into contact with the oxygen in the air, preventing oxidation. Inert argon is well suited for this purpose as it is non-toxic and relatively inexpensive. The equipment for argon welding comes in two types, TIG and MIG. In both cases, the machines are equipped with a non-consumable tungsten electrode. The difference is that TIG uses separate hard facing rods, but in MIG, the wire is fed automatically from the spool, for which people often call this method semi-automatic.

Request for a quote

MR CO. LTD.

Ukraine

Aluminum alloys are among the materials characterized by poor weldability. Any experienced welder will confirm that to work successfully with aluminum, you need to have a lot of experience and know all the features of this metal. Technologically this process is quite complicated and a lack of experience can lead to manufacturing defects. Due to its high thermal conductivity, low melting point and the presence of a refractory oxide film, welding aluminum requires special equipment. TIG welding with shielding gas using aluminum alloy hard facing rods provides excellent joint quality.

Request for a quote

MR CO. LTD.

Ukraine

Two methods are used to bend pipes at a certain angle, hot and cold. We provide cold-bending pipe services. Products made of plastic metals and alloys lend themselves well to this technology. Bending pipes by this method is possible only if their diameter does not exceed 100 mm. This type of machining is done manually or through special bending machines. When bending round pipes, it is essential to avoid dents that decrease their inner diameter. The pipes should have smooth bends along a certain radius and a circular shape in the bend areas. Our pipe bending machines allow you to get a quality bend in a few rolls.

Request for a quote

MR CO. LTD.

Ukraine

Powder coating of metal is a popular technology that allows you to reliably protect the metal from corrosion while giving the product an attractive appearance. Each powder coating starts with pre-treatment. The surface of the metal is cleaned of rust, dirt and grease by chemical or mechanical means. Next, the product is placed in the paint chamber, where charged paint particles are sprayed over the surface with a paint gun. The products covered with a thin layer of powder are transferred to the furnace. Heating causes the paint to polymerize. As a result, a strong polymer film of the desired shade is formed on the surface.

Request for a quote

MR CO. LTD.

Ukraine

The process is performed in closed chambers, where a jet of millions of glass microbeads, moving in a stream of compressed air, is directed on the product surface using a specialized gun. The abrasive removes all contaminants from the surface without changing the part geometry or damaging the product. It allows even fragile materials to be handled gently with this method. Controlled plastic deformation of the metal surface forms a light work-hardening that improves the service performance of the product. Due to the matting effect, this method is often used for finishing aluminum parts.

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

NOVELTY STEEL

Turkey

Decorative metal panels have emerged as a prominent feature in modern architecture and housing projects. Laser-cut metal panels are architectural elements crafted using CNC laser cutting technology.

Request for a quote

ESTIMET SP Z O.O.

Poland

Bøying av plater på numerisk styrte kantpresser, opptil knekkelinjens lengde (bøyingslenge) 5000mm

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in the production of metal welded brackets according to the individual drawings and requirements of our customers. We are able to provide high-quality products that precisely meet the needs of our clients. Our production is based on the latest technologies in the industry. We utilize laser cutting and CNC bending of sheet metal, which allows us to achieve high precision and repeatability in our products. Thanks to robotic grinding, we are able to achieve optimal surface quality, ensuring consistent and aesthetically appealing surface finishing. One of the key aspects of our production is ensuring a high standard of corrosion resistance and safety for our customers. For this purpose, we use top-of-the-line COSTA machinery, which allows us to round the edges of components with precision and efficiency. This process not only enhances the aesthetics of our products but also increases their durability and resistance to external influences.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in manufacturing precise sheet metal components according to customer drawings and specifications, whether in steel, stainless steel, or aluminum. Our commitment to precision is ensured through the use of ACB sensors equipped in our bending and forming machines, allowing us to achieve highly efficient production repeatability. Additionally, we utilize 4 press brakes from TRUMPF company - models 7036, 3066, 5170, and 5085 - which enable us to bend sheets with a maximum width of 4250 mm. However, considering laser cutting capabilities, we bend sheets with a maximum width of 4000 mm, ensuring seamless integration of all production processes.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free