NORMIT

Slovakia

Manufacturer/ Producer

NORMIT

Slovakia

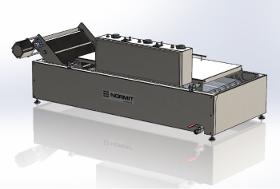

The fryer is designed specifically for professional gastronomic cuisine of hotels, restaurants, and cafes, as well as catering companies and small manufactures. The universal conveyor with its compact dimensions provides a large efficient area of frying. The heating power in the 1-phase version of the fryer is -4 kW, in the 3-phase version 8/12 kW. Technical specifications: Dimensions (LxWxH): 1399x491x400 mm (basic version) Weight: about 60 kg. The working volume of oil: up to 80 liters Working width: 0.35 m Working length in oil: 0.88m Cooking area: 0.4 m² Heating power: 1-phase version: 4kW (cheaper model), 3-phase version: 8/12 kW Maximum heating temperature: 200 ° C (at high temperatures it is better to use special oil for deep frying)

Request for a quote

NORMIT

Slovakia

Drum coater provides easy operation and coating for snack. It’s used for seasoning, salting, adding sugar, adding various ingredients (cinnamon, vanilla, spice ...). Adjustable tilt frame assembly and design exposes each piece of product to the application of liquid and dry coatings. Depending on the application, the dosing of liquids may be through a dosing, perforated pipe and pump or hopper and conveyor system for dry materials. Depending on additional components, the system may be cyclical or continuous. Coating Drum Applications: •Different types of nuts •Chips •Pasta •Cereals •Meat Advantages •AISI 304 stainless steel cylinder. •Motor assembly with variable speed controller. •Variable tilt, stainless steel frame assembly. •Control panel. •Portable casters with brake assembly. •Equipped with paddles for even sprinkling •Drum rotation speed adjustment included •Adjusting the performance of the inclined installation •Possibility to change the height of the supporti

Request for a quote

NORMIT

Slovakia

It is a versatile device for transporting products to a height. It can be used to transport large, small, light or heavy products. The conveyor works very accurately at slow and high speed. Usually it is part of various technological lines and serves for the transport of small products within the line. The conveyor enables fast and efficient transport for a wide range of products. Benefits: •Low water consumption for cleaning •Affordable price •High quality and resistance •Energy savings of 30% •Solid steel construction Advantages: •Fast cleaning and maintenance •Simple installation •Adjustable belt speed •High accuracy conveyor •Low noise •Made of high quality stainless steel AISI 304 •50L hopper volume is at a given angle 38 ° •Conveyor has an adjustable height of 540-840 mm •Conveyor itself can be moved and the angle of the conveyor inclined from 20 ° to 0 °. •Belt PVC.

Request for a quote

NORMIT

Slovakia

Tilting pan with indirect heating and integrated stirrer is designed for frying, steaming, cooking vegetables, fish, meat, sauces, pasta with constant stirring, eliminating the risk of burning or uneven heat treatment. Processes: •Stewing •Cooking •Evaporation •Frying •Deep frying Advantages: • Equipped with a duplicator and electric heating elements. • Fast heating and high thermal efficiency. • Reinforced stirrer with Teflon scraper, which in continuous mode cleans not only the entire bottom, but also the walls of the pan, ensuring a perfect result. • Tilt ensures complete unloading of the working container. • Made of high-quality food-grade stainless steel AISI304 or AISI316L. • Easily sanitizable • No dead zones. Technical specification: Working volume up to 130l Recommended Termooil heating Frying temperature up to 160 C Stirring device: yes Product unloading type: electric driven tilt system Dimensions (LxHxW): 1800x1900x1400 mm Weight: 350 kg

Request for a quote

NORMIT

Slovakia

The frozen blocks flaker is intended for flaking of frozen blocks of meat, fish and poultry (including with bones), as well as frozen blocks of juice, butter, margarine and similar products coming directly from cold storage and without prior defrosting. Areas of use: • food industry • meat processing enterprise Advantages: •Rolling storage container can be fixed •Built-in pneumatic feed drive •Double-sided knives allowing 2 times longer service life without sharpening •The cut thickness is adjustable •It can be placed on a non-horizontal surface (with a tilt angle up to 15 degrees) with the aid of adjustable supports. •The adjustable blocks' feeding speed. •A block can be ground up both into thin flakes up to 2 mm in size, as well as into thick pieces up to 100 mm Technical specification: •Motor power- 11.5 kW •Dimensions (LxWxH)- 2310x1155x1326 mm •Maximum size of meat- 600x600x23 mm •Productivity up to - 6000 kg / hour

Request for a quote

NORMIT

Slovakia

Destoner / washer is designed for pre-washing and stoning of potatoes, carrots, beets and other root vegetables. Destoner separates stems and floating parts such as leaves and stalks. It consists of a rectangular hopper into which water is supplied and a vertical pipe with a discharge conveyor screw. The product to be destoned is inserted into the water hopper and lifted gently with the water into the pipe by means of the screw rotation. Rotational movement lifts the product and allows water to drain off the sides of the screw. Heavy parts that water cannot pick up remain on the bottom of the hopper. The pure product (without stones) comes from the top of the screw. Benefits: •Gentle to a product •Washing & destoning in one compact machine •Simple operation & maintenance. •Made of high quality stainless steel •Adjustable screw speed using a frequency converter Technical data: •Dimensions (LxWxH): 1100x584x2022 mm •Power: 0.75 kW •Productivity: up to 2000 kg / hour

Request for a quote

NORMIT

Slovakia

Our company offers honey creaming equipment in a new design with gravity mixing. We offer many different capacity honey creaming machines from 90 up to 2300 kg atmospheric and vacuum. Our main advantage of the honey creaming machines - cream honey in 4 hours! A characteristic feature of the new series of honey creamer is gravity mixing, which is 20-25% more efficient than conventional mixing! Honey creaming machine - Operations: •decrystallizing •recrystallizing (reducing crystal proportion) •regulated crystallizing •structural enhancements (consistency) •homogenizing Honey creamer - Features: •Honey humidity prior processing: 17% •Stainless steel AISI304 The installation can be equipped with: •vacuum water ring pump •vacuum ejector VENTURI.

Request for a quote

NORMIT

Slovakia

Our company offers honey creaming equipment in a new design with gravity mixing. The main advantage of the machinery - cream honey in 4 hours! The device is designed for 450 kg. honey loading for one batch. Model This machine is ideal for cream honey production. The inclined design also makes it easier to unload the product after processing, because the centrifugal force and gravity force !! Based on our many years of experience in the production of honey creaming equipment, our experts have developed equipment that uses creaming technology - the method of mechanical grinding - with strong cutter knives. Technical specification: Geometric volume -300 l Installed power -12,1 kW Material - AISI 304 Dimensions (HxWxL)- 1374x1574x1107, mm Weight- 370 kg

Request for a quote

NORMIT

Slovakia

In stock ! MULTIVAR PROFI is designed for vacuum frying of semi-finished products in oil with its subsequent removal from the product. It is made in S, L, XL sizes. The fryer is intended for: • frying • deep-frying under vacuum • mixing / stirring (with the purchase of a special mixing device) Benefits: •Simple and easy to operate •Ability to adjust and regulate temperature, vacuum, on / off and rotation speed of the stirrer / basket, tilt of the installation, processing time. •Special inclined design of the working vessel •Special basket - centrifuge, which effectively and quickly removes excess oil from the product. •Vacuum processing removes air voids from the product Technical data: •Basket volume, l 9 •Maximum basket load, kg 2 •Working fluid volume, l 7.5 •Installed heating power, kW 6 •Vacuum pressure, (max) Bar -0.8 •Maximum heating temperature, ⁰С 130 •Dimensions (H ** / L / W), mm 675/940/656 •Material * AISI304

Request for a quote

NORMIT

Slovakia

FEATURES: multi-zone tempering system provides efficient heat exchange and the formation of stable coca butter β-crystals. measurement of inlet and outlet temperatures in each zone PLC control panel, accurate correction program temperatures the unique design of the scaler and discs guarantees uniform mixing manufacturing material AISI 304 or 316 Constant viscosity glaze The glaze, after passing through the machine, has a constant viscosity, gives a perfectly glossy surface when cured and becomes stable (the glazed product does not melt in the hands). PRODUCTS: dark chocolate milk chocolate icing cocoa butter ADDITIONAL OPTIONS: chiller de-crystallizer

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free