- europages

- >

- Agriculture - Machines & Equipment

- >

- NUT TECHNOLOGY

NUT TECHNOLOGY

Ukraine

Manufacturer/ Producer

NUT TECHNOLOGY

Ukraine

A dryer is an equipment designed to dry inshell walnuts after harvesting, washing or cleaning the green pericarp. Drying of walnuts is a necessary step in the walnut business because the quality of the kernel and the storage time of the walnut in the shell depend on it. Advantage of Walnut Dryer: Dries the entire batch of nuts evenly thanks to the nut stirring system; Prevents nut spoilage – wet or unevenly dried nuts quickly become moldy; Does not spoil the quality of the nut – drying in the sun can cause the kernels to darken; Cost effective – energy saving system reduces heating time and costs; Shorter drying times compared to natural drying under the sun; Autonomy – does not require human participation in the drying process; Compactness – takes up little space; Ease of operation – one person is enough to load and control the dryer. Principle of operation: the nut is loaded into the hopper using the loading conveyor and the required heating temperature is set.

Request for a quote

NUT TECHNOLOGY

Ukraine

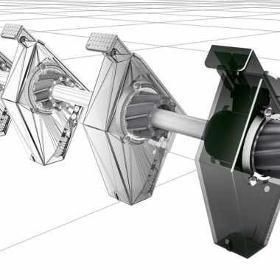

The industrial line is a complete range of equipment for processing almonds on a production scale. The line is equipped with such a volume of equipment that will automate your production as much as possible, reduce labor and reduce manual walnut bulkheading to a minimum. Drum nutcracker for almonds is an equipment for high-quality processing of almonds on an industrial scale. The nutcracker provides gentle cracking with maximum whole kernel yield – up to 90%. This model is ideal for use in medium and large enterprises. Nut calibrating machine is intended for sorting almonds in shells into fractions by sizes from small to large for further high-quality and cost-effective processing of almonds on industrial nutcrackers. Calibrator sorts almonds in shell into two sizes. The vibrating sieve is designed for screening and sorting almonds in the shell according to size.

Request for a quote

NUT TECHNOLOGY

Ukraine

The industrial line is a complete range of equipment for processing hazelnuts on a production scale. The line is equipped with such a volume of equipment that will automate your production as much as possible, reduce labor and reduce manual walnut bulkheading to a minimum. Drum nutcracker for hazelnuts is an equipment for high-quality processing of hazelnuts on an industrial scale. The nutcracker provides gentle cracking with maximum whole kernel yield – up to 90%. This model is ideal for use in medium and large enterprises. Nut calibrating machine is intended for sorting hazelnuts in shells into fractions by sizes from small to large for further high-quality and cost-effective processing of hazelnuts on industrial nutcrackers. Calibrator sorts hazelnuts in shell into two sizes. Vibrating sieve and aspiration is designed for screening out shells and dust from the nut kernel and sorting the kernel into fractions.

Request for a quote

NUT TECHNOLOGY

Ukraine

The industrial line is a complete range of equipment for processing nuts on a production scale. The line is equipped with such a volume of equipment that will automate your production as much as possible, reduce labor and reduce manual walnut bulkheading to a minimum. Walnut cracking machine (100 kg/h) is an equipment for high-quality processing of walnuts on an industrial scale. The nutcracker provides gentle splitting with maximum whole kernel yield and is suitable for processing walnuts of any size. This model is ideal for use in medium and large enterprises. The industrial nutcracker is equipped with a conical split type, so that the nuts are cracked as gently as possible. The calibrator is intended for sorting nuts in shells into fractions by sizes from small to large for further high-quality and cost-effective processing of nuts on industrial nutcrackers that require preliminary calibration of the nut.

Request for a quoteNut Technology is a full-cycle manufacturer of equipment for walnuts - from harvesting walnuts in industrial gardens to sorting the finished kernel. The Nut Technology company began its journey in 2012 with the production of handmade nutcrackers. Today, based on many years of experience, it manufactures industrial complexes with a capacity of more than 1 ton per hour. Our range includes equipment for sizing nuts, peeling with a maximum percentage of whole kernels, sorting kernels with shell separation using aspiration, inspection tables, equipment for peeling, washing, crushing and drying nuts, equipment for automating your production and a small technique. , which has become legendary in the Ukrainian and international market. Our advantages: ⁃ We have been working with nuts for over 10 years and know the peculiarities of their processing ⁃ Ability to test equipment before ordering in your own showroom ⁃ Customer support 24/7 ⁃ Warranty and service ⁃ Production of equipment for individual orders Today Nut Technology is more than a manufacturer of equipment. We raise the culture of walnut consumption, teach them how to properly handle walnuts and provide access to communities to find partners and clients around the world.

Website

Company info

Key figures

-

- Company headcount

- 1 – 10

Organisation

-

- Main activity

- Manufacturer/ Producer

Activities of NUT TECHNOLOGY

- Agriculture - Machines & Equipment

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in precision machinery,after processing, local sandblasting is carried out.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

Seeder housing as a completely assembled assembly group - this is used in mechanical seeders for metering the seed or fertilizer.

Request for a quote

ATMOSFER MACHINERY

Turkey

We are proud to present our state-of-the-art multifunctional production plant, a groundbreaking innovation designed to streamline and simplify the process of manufacturing various solutions, including liquid fertilizers such as NPK, UAN, and more, as well as AUS solutions like AdBlue. This fully automatic and smart production plant is set to revolutionize the industry of liquid fertilizer.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company has 25 years experience for manufacture different kinds of gears.And our company has many advanced production equipments. such as CNC forming grinding wheel grinding machines, gantry machining centers, four axis and five axis machining centers, CNC lathes, CNC gear shapers, CNC milling machines, CNC hobbing machines, gear chamfering machines.and more than 40 sets of processing and testing equipment. we can provide various professional production services such as precision gear wheel machining, CNC machining, CNC turning machining, and so on.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free