PARSMEGA MAKINA - Agricultural Machines : Flour Milling Machines Manufacturer

Turkey

Manufacturer/ Producer

PARSMEGA MAKINA

Turkey

PMX45 cold pressing machine, designed and produced by PARSMEGA, is a screw press machine capable of squeezing all kinds of oilseeds. Our machine is suitable for all kinds of seeds; canola, flax, sesame, sunflower, hemp, safflower, soybean, hazelnut, peanut, cotton, grape seed, rapeseed, linseed, cumin, mustard, poppy, nettle, bitter almond seed, tomato, hazelnut, apricot seed etc. .

Request for a quote

PARSMEGA MAKINA

Turkey

Grain drying machines can dry all kinds of wheat, corn, barley, canola, soybean, etc. It reduces the humidity level of grain plants to a level that can be stored in silos. With its perfect design, it has a drying capacity of up to 50 tons at 5 tons per hour. Our machines, made of superior quality stainless steel, are designed to serve for many years.

Request for a quote

PARSMEGA MAKINA

Turkey

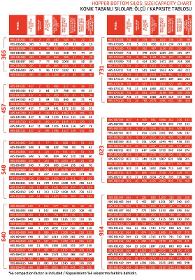

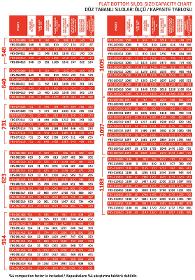

CSI silo wall sheets have a minimum tensile strength of 900,000 kgf/cm2 (63,200 Psi). These values clearly demonstrate our superiority over other silos in the market. ESI; offers strong, purposeful and durable commercial steel silos. Steel sheets made of very durable steel, wide corrugation spacings, heavy galvanized steel silo poles and matching roof gutters are some of the quality features available. Diameters of our commercial type steel silos; It has different dimensions from 4.57 m to 32 m. Extra different sizes are available in every diameter.

Request for a quote

PARSMEGA MAKINA

Turkey

Thanks to the roof design with 300 angle, it is ensured that the grain flows easily into the silo. In this way, very easy air circulation occurs within the grain pile in the silo. Roofs are manufactured to withstand loads from 7000 kg to 14000 kg. Our designs are designed to withstand 154 kg/m² standard snow weight and 170 km/h standard wind speed. Silos with a radius of 3.65 m - 12.80 m have a single layer reinforced roof system. This type of roof structures can withstand loads heavier than 907 kg (2000lb) and live loads of 78 kg/m2 (16 psf). A two-stage roof system is used in silos with a radius of 14.63 meters or more. This type of roof structure is suitable for loads of 4536 kg or more and is resistant to live loads of 122 kg/m2. "May Your Cereals Be SAFE" The roof panels are triangular in shape and trapezoidal on both sides with a depth of 90 mm. Roof access covers are available in all roof systems.

Request for a quote

PARSMEGA MAKINA

Turkey

Funnel-shaped silos have an angle of 45º or 60º, which allows the grain to flow with its own fluidity. However, 45º conical bottoms are used for grains, and 60º conical bottoms are used for feeding purposes, moist grains or low-fluidity materials. Conical bottom silos are produced from 5 tons to 1,000 tons. Generally, they are operated in a continuous discharge state. Low energy consumption and operating costs during the unloading process are one of the reasons why these silos are preferred. Special steel structures, chassis and platforms have been developed for conical bottom silos. These steel structures are placed at the bottom of the silo to add height to the silo unit. These combined systems are designed for easy and healthy loading of wagons.

Request for a quote

PARSMEGA MAKINA

Turkey

Ladders and platforms are produced completely modularly with galvanized sheets. Holes; It is drilled with the latest technology punching machines to facilitate screwing operations. Exterior and interior stairs; It can be joined to existing holes using fasteners. Standard silo external ladder safety system allows people to reach the roof safely. The rest platform is placed under the roof entrance cover for easy access to the roof or for your safety when entering the silo.

Request for a quote

PARSMEGA MAKINA

Turkey

Our drum type Pre-Cleaning Machines; It is produced in the capacity range of 20 - 100 tons per hour. With the ÇSI Pre-Cleaning Machine, all unwanted foreign substances (garbage, dust, straw, etc.) in all kinds of grains (wheat, barley, corn, canola, soybean, etc.) are perfectly separated at a level that does not require cleaning again. Thanks to its airlock and cyclone as well as its excellent filter, it leaves absolutely no waste in the environment. Our sieves, which are designed according to the structure of all kinds of products, are easily mounted on the machine. Thanks to the brushes placed on the sieves, the sieves constantly clean themselves as the machine operates. With its high suction power dust collection and filter system, it does not leave any dust waste in the environment. The Pre-Cleaning Machine, designed by ÇSI engineers using advanced technology, will provide the cleaning you need for many years.

Request for a quote