PRAGMA BUYING SRLS

Italy

Agent/ Representative

PRAGMA BUYING SRLS

Italy

hot dip galvanizing plants, we are one of those few companies who engineer and design on their own know how and realize by themselves all components and equipments, making up lines of production. Moreover, we like to underline that we guarantee and assure the maximum of the efficiency for what the assistance after sale is concerning. In this connection and in case you are looking for a Company who can support you in designing of new galvanizing plants or to improve the performance of your existing plant please do not hesitate in contacting us. Our production : • Galvanizing furnace; • Dryers; • Enclosures on the galvanizing furnaces; • Complete enclosures on pretreatment area; • Aspiration and filtering units for galvanizing fumes; • Pretreatment tanks in PP; • Heat exchangers to heat the pretreatment tanks; • Aspiration and neutralization units for acid fumes; • Heat recovery sistems; • Adjustable height jigging stations; https://www.youtube.

Request for a quote

PRAGMA BUYING SRLS

Italy

THE AC ELECTRIC ARC FURNACE (EAF) FROM STS IS THE IDEAL MELTING UNIT FOR THE PRODUCTION OF ALL TYPES OF STEEL, FROM STANDARD CARBON GRADES TO HIGH-ALLOYED AND STAINLESS STEEL GRADES. Its overall furnace performance can be additionally enhanced with the latest oxygen- and carbon-injection technologies. has fully developed his own technology in EAF. Melting process is controlled by STS high performance Electrodes regulation system MAIN DESIGN FEATURES Split Type Design Furnace Shell, Replaceable type for minimum relining downtime. Eccentric Bottom Tapping Type (EBT ). Current Conducting Electrode Arms. Furnace movements and electrode arm hydraulically actuated. Inert gas bottom purging facilities. Automatic Feeding Of DRI.

Request for a quote

PRAGMA BUYING SRLS

Italy

Continuous stainless steel plants for ethanol dehydration by a physical / chemical process called adsorption. In this process water molecules are trapped on the surface of adsorbing solid, called molecular sieve, removing water from the mixture to be dehydrated. During the adsorption process molecular sieves tend to become saturated, that means, in order to restore their dehydration capabilities, after the absorption phase a regenerative one must be carried out.

Request for a quoteAgent/ Representative

Via seneca 37

72100 Brindisi - Italy

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

TABELARAIZ

Portugal

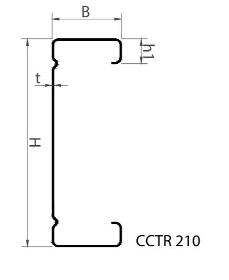

Profiles produced "C' Section characterized as CCTR 210. Discover our catalog here

Request for a quote

MICRON AMERICA

Turkey

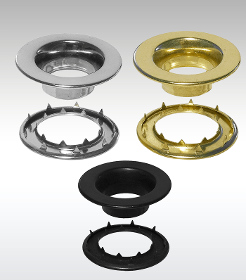

Rolled Rim Grommets with Spur Washers are available in brass with a selection of finishes including nickel plated and brass and military black.Specifically engineered to interlock, the teeth of the washer grab the material ensuring a rugged and rigid setting. This multipurpose grommet and washer combination can be used in a variety of materials including industrial fabrics, marine canvas, boat covers, awnings, and heavy duty vinyl tarps as long as a hole has been pre punched in the material. Please take a look to the chart in order to find the dimensions you need for every size and finishes of rolled rim grommet and spur washer manufactured by Micron America.

Request for a quote

MICRON AMERICA

Turkey

Brass grommet and teeth washer provide rugged and unyielding setting for a wide variety of applications. Manual, semi automatic and fully automatic grommet setting machines easily set grommets and plain washers ensuring installation runs smoothly and efficiently. This multipurpose grommet and washer combination can be used in a variety of materials including industrial fabrics, canvas, leather and heavy duty vinyl tarps, as long as a hole has been pre punched in the material. Please take a look to the chart in order to find the dimensions you need for every size and finishes of sheet metal grommet and teeth washer manufactured by Micron America.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free