SCHNELL SPA

Italy

Manufacturer/ Producer

SCHNELL SPA

Italy

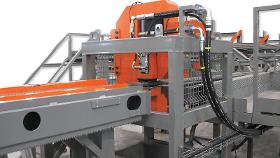

Bidirectional automatic bar shaping machine from bar, with 2 bending heads for the production of shaped wires and cuttosize bars using wires up to Ø 28 mm (#8). Driven by digital electric servomotors. Bar Wiser 28 bar shaping machine is equipped with Max. pulling speed 180 m/min (600 ft/min) 2 bending units (upper and lower) Clamp for extraction of the end part of the bar Virtual mandrel Web Teleassistance Automatic loader Genius (Optional) Bar Wiser 28 Pack 0 Storage rack pneumatically operated.

Request for a quote

SCHNELL SPA

Italy

Bidirectional automatic bar shaping machine from bar, with 2 bending heads for the production of shaped wires and cuttosize bars using wires up to Ø 32 mm (#10). Driven by digital electric servomotors. Bar Wiser 32 bar shaping machine are equipped with Max. pulling speed 180 m/min (600 ft/min) 2 bending units (upper and lower) Clamp for extraction of the end part of the bar Virtual mandrel Web Teleassistance Automatic loader Genius (Optional)

Request for a quote

SCHNELL SPA

Italy

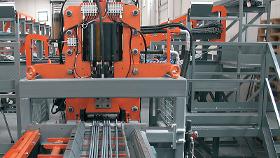

Thanks to its innovating system, SBL takes, counts and moves the bars for shearline feeding in a completely automatic way. With SBL you save money and enhance productivity due to its flexibility. Advantages 1. ‘SBL’ is extremely fast so it can feed more bars compared with manual feeding. The result is higher productivity per hour for any kind of shear line. 2. No need of hard and dangerous bar handling so no need of people for such operation resulting in great money saving. 3. The elimination of manual bar feeding enhances security at job site. 4. “SBL” special structure makes it possible to feed shearlines with higher a number of bars of different diameter and length resulting in a. drastic reduction in machine setup; b. plant overall dimensions determined by clients’ room available; c. higher flexibility of the plant.

Request for a quote

SCHNELL SPA

Italy

Integrated plant to cut, optimize and stock the bars, based on a shear CHV 160, mounted on a fixed frame, with blade of 160 mm (6''), VBM1 measuring and cutting track with mobile ledge, with oneside unloading.

Request for a quote

SCHNELL SPA

Italy

Integrated plant to cut, optimize, stock and handle the bars, suitable for mass productions, based on a shear CGS 300, mounted on a mobile frame, with blade of 300 mm (12''), VMT measuring and cutting track to cut the bars to size and unload them on the right or left. In the VMT SUPERFAST version, the roller conveyors and the unloading systems are divided into two parts individually operated. This ensures a much faster working cycle.

Request for a quote

SCHNELL SPA

Italy

Integrated plant to cut, optimize, stock and handle the bars, suitable for mass productions, based on a shear CGS 500, mounted on a mobile frame, with blade of 500 mm (20''), VMT measuring and cutting track to cut the bars to size and unload them on the right or left. In the VMT SUPERFAST version, the roller conveyors and the unloading systems are divided into two parts individually operated. This ensures a much faster working cycle.

Request for a quote

SCHNELL SPA

Italy

Stationary bars measuring and cutting plant, with shear operated by servomotor. It has a second transfer rack parallel to the cutting unit. This way, cut bars can be placed on the whole length of the racks optimizing the use. This system enables a better cutting optimization, reducing the amount of scraps. Electromechanical feeding and cutting head; Feeding by means of servomotor; Console with graphic colored touch screen LCD 8’’.

Request for a quote

SCHNELL SPA

Italy

Electromechanical automatic rebar cutting bench with 3 transfer roller conveyors. Besides being flexible and fast, its electromechanical technology ensures high accuracy; minimum noise production; reduced power and air consumption; reduced maintenance.

Request for a quote

SCHNELL SPA

Italy

Electromechanical automatic rebar cutting bench with 6 transfer roller conveyors. The cutting bench 'BAT 6' represents the ideal solution for those working large numbers of smallsized orders and it is especially designed for civil housing. Thanks to 6 different chambers optimise processing of small orders even without the transfer unit. Besides being flexible and fast, its electromechanical technology ensures high accuracy; minimum noise production; reduced power and air consumption; reduced maintenance.

Request for a quote

SCHNELL SPA

Italy

Electromechanical automatic rebar cutting bench with 3 transfer roller tracks and a second additional rebar conveyor. Thanks to the second transfer track, parallel to the cutting unit, cutbars can be placed along the whole length of the roller track optimizing the use. This means that the same roller track can be used to store different orders. Basically, it is as if you had a much greater number of roller tracks allowing a better cutting optimization thus reducing the quantity of scraps. Besides being flexible and fast, its electromechanical technology ensures high accuracy; minimum noise production; reduced power and air consumption; reduced maintenance.

Request for a quoteManufacturer/ Producer

Via Sandro Rupoli, 2 (ex Via Borghetto) zona Ind. San Liberio

61036 Colli Al Metauro - Italy