- europages

- >

- Printed circuits

- >

- SILGA SPA

- >

- products

SILGA SPA

Italy

Service Provider

SILGA SPA

Italy

A new way of conceiving electronics has revolutionized the possibility of freedom of shape and choice of materials, integrating functionality, flexibility and design. The world has moved towards the generation of the Touch Screen, the integration of functions and freedom in forms, so much so that electronics have also become part of it. The possibility of using flexible substrates and inks which, through an additive process, can recreate very complex patterns and very thin tracks, now allows the desired electronics to be integrated into 3D geometries. Furthermore, the introduction of Printed Electronics has created the perfect combination between electronics and plastic materials, allowing, through the use of polymeric substrates, the co-molding of PCBs on plastic supports: In mold Electronics. Maximum product integration, optimizing production processes whose phases are drastically reduced.

Request for a quote

SILGA SPA

Italy

Lightweighting, freedom of design and cost reduction are the drivers for every application and sector. For this reason, Silga is increasingly called upon by its Customers to become a partner in the development of solutions that achieve this objective. Especially if they are non-standard solutions. One of the most important and successful is that of FLEXIBLE HEATERS . In this area, in fact, skills related to: Flexible PCB's Alternative materials Chemical etching capability of metals other than copper Know How in using functional inks Exclusive surface finishes developed by Silga. Production lines adequate for the required volumes

Request for a quote

SILGA SPA

Italy

IMS (Insulated metal substrate) technology allows the mounting of power components directly on a highly thermally conductive printed circuit board . The result is a compact and reliable solution which, thanks also to the reduced cost compared to systems with traditional heat sinks, is finding more and more application in sectors where effective dissipation of the heat generated by electronic components is required, such as of Lighting, Automotive and Power Supply . The devices can operate at lower temperatures with a guarantee of greater reliability and lifespan , avoiding the assembly phases of mechanical heat sinks. The assembly cycle is simplified and can in some cases be reduced to just the SMT assembly operation. The availability of dielectric layers of different nature and thickness offers many design possibilities from a thermal and electrical insulation point of view. It is possible to use different materials with both aluminum and

Request for a quote

SILGA SPA

Italy

To effectively respond to the technological expectations of its customers and satisfy the different market needs, Silga is able to offer a wide and complete range of products ranging from printed circuits with standard characteristics to highly complex ones. Silga offers customizable solutions for single-copper PCBs , double-sided PCBs with metalized holes and multilayer PCBs , as well as radio frequency PCBs, for numerous applications in the automotive, EMS, household appliance, lighting, medical and industrial sectors.

Request for a quote

SILGA SPA

Italy

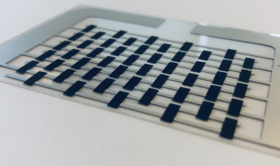

To effectively respond to the technological expectations of its customers and satisfy the different market needs, Silga is able to offer a wide and complete range of products ranging from printed circuits with standard characteristics to highly complex ones. Silga offers single-copper flexible PCBs , double-sided flexible PCBs with metalized holes (PTH), flex therm for heat dissipation, Gigaflex for the sensorized connection of the battery pack to the BMS in e-vehicles and Flexible Heaters for heating and removal of the condensation. Silga flexible PCBs find application in numerous sectors such as automotive, EMS, industrial, medical and wearable.

Request for a quote

SILGA SPA

Italy

Dual access copper connections are an innovative technique for the creation of single-sided FPCs (flexible printed circuits), which however also require a connection on the other side. Thanks to the dual access copper technique developed by Silga it is possible to directly connect the tracks of a single-sided FPC to a support, safely and effectively. The advantages? Among all the possibility of avoiding the use of nickel tabs for the connection; in fact, the dual access copper technique guarantees direct contact and consequently greater robustness by virtue of the fact that additional welding is not required (critical aspect of the robustness of the products, also linked to the stress generated by dimensional variations), which is instead necessary for nickel tab. Furthermore, in the case of connection to battery packs, based on customer needs in terms of materials used in the busbars and the type of welding

Request for a quote

SILGA SPA

Italy

Silga designs and creates new applications of high-performance circuits for the automotive sector in the field of e-mobility, such as Gigaflex , flexible printed circuits for batteries , intelligent solutions for sensor-controlled connections of battery cells and systems for connecting modules to the BMS . This solution allows for a drastic reduction in the size of battery connection systems, eliminating any cumbersome wiring. In this way, flexible printed circuit boards for batteries become the perfect mix between connectivity , performance and lightness .

Request for a quote

SILGA SPA

Italy

FPCs solutions for batteries include Flexible Heaters , an innovative technology developed for the thermal management system of the batteries; in this way, the performance of the battery is improved, prolonging its life, especially when it is located in areas with extreme climatic conditions. Flexible heaters can be made using the traditional technique or the new Printed Electronics technology , with the possibility of also using PTC inks for automatic temperature regulation. Furthermore, the “Made in Silga” Flexible Heaters offer the possibility of integrating special finishes to guarantee excellent performance in any working condition.

Request for a quoteService Provider

Via Carl Marx 54

60022 Castelfidardo - Italy