SUVIS GMBH

Germany

Service Provider

SUVIS GMBH

Germany

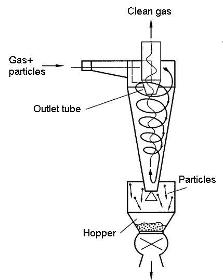

The gas cyclone belongs to the mostly applied technical separators, because it has applicationwise some fundamental advantages. One of them is certainly the fact that its construction does not show any movable components. For the large variety of different kinds of dispersed (particulate) phases (for example dust particles, metal chips, wooden waste, liquid droplets) and different gas conditions (pressure, temperature) the lay out and computation of a cyclone is still a complex task. Suvis has specialised in the development and lay out of cyclone separators and can offer professional solutions and consulting in the area of gas cyclones. Many years of experience gained through numerous cyclone development projects results in optimal solutions for our customers. A cyclone separator applies centrifugal forces and represents an effective apparatus for separating gas, liquid or solid particles from a continuous phase in chemical, process or environmental engineering.

Request for a quote

SUVIS GMBH

Germany

Hydro cyclone units are applied in order to separate coarse and fine solid particles from liquids . These type of separators are particularly capable of separating sand, starch, and other finely distributed materials. With hydro cyclones it is possible to separate fine particles online during the process. Hydro cyclone units are used to separate, classify, and to thicken suspensions. Also, these units are used to purify ores and minerals. Also, in fibre technique and paper industry they are applied in purification processes to separate dirt. Hydro cyclones are frequently run in parallel mode. The lay out and design of hydro cyclones are performed empirically similar to the duct cyclones. In the lower flow region of a hydro cyclone an air swirl forms during the separation process, which is not substantially influencing the cyclone flow. Because of the large dimension of the cyclone, wall friction has much more influence on the flow.

Request for a quote

SUVIS GMBH

Germany

The Suvis GmbH also deals with the application of modern numerical methods for the lay out and optimisation of various separator types like cyclones. A typical application of these computation methods is the computer aided investigation of particle separation from gases in cyclones. The prediction of the separation efficiency allows the reliable optimisation of conventional cyclones and the development of completely novel high efficiency cyclones. With that, very often expensive filter units, wet cleaner, or costly electro filters can be replaced or completed. When applying numerical methods (CFD simulations) to cyclones one encounters the problem of strong curvature of the stream lines because of the resulting strong swirl flow and the abrupt change of flow direction towards the outlet tube. This means that the assumption of isotropic turbulence is not useful anymore.

Request for a quote

SUVIS GMBH

Germany

Another working area of the Suvis GmbH is the field of innovative sensor systems applied to particle and flow measurements taking into account microsystems. We develop novel flow and particle sensor systems for the application in environmental technology, process and mechanical engineering, and automotive technology. Important aspects are robustness and economicalness of the complete sensor system in order to create for the above mentioned application fields practical and affordable solutions. The respective sensor system will be developed as a whole solution. This means besides the hardware set up that we also take care of the evaluation of the sensor signals with our own solutions. We develop from scratch up to prototype level including periphery technology development. Please contact us for a not binding offer. We would like to know more about your challenge!

Request for a quote

SUVIS GMBH

Germany

The Suvis GmbH offers flat pressure sensors (see photograph), which we produce ourselves and which can be used for classical static pressure measurements on solid surfaces like automobile frames. The flat pressure sensors are applied especially in cases where one cannot place a borehole in the respective surface. Hence, flat pressure sensors represent “transportable” static pressure boreholes, which one can glue on the surface of the flow body. The photo shows typical flat pressure probes. Typical dimensions are 17 mm (diameter of the flat disc) and 0,5 mm as diameter of the pressure borehole. The disc consists of bronze, while the measurement tube is made of high quality steel. In order not to interfere with the flow the discs are chamfered around their periphery. When producing the flat pressure sensors for you we can take your individual design requests into account. Simply contact us for a nonbinding offer.

Request for a quote

SUVIS GMBH

Germany

The particle image velocimetry (PIV) is an optical noninvasive working flow velocity measurement method. The flow field is made visible by introducing into the fluid small buoyancy neutral particles – the so called tracers. The particle flow then is illuminated with the aid of a light sheet and recorded at two defined different times within a small time interval with a digital camera. Because the particle move within this time interval with the flow, one can calculate the particles velocity by knowing its path between the two moments of illumination. The result is a velocity vector field of the flow. Here, we assume that the particles are small and follow the flow without any slip. Compared to local methods like LaserDopplerVelocimetry (LDV) with the ParticleImageVelocimetry one can reconstruct a whole flow region An extension of ParticleImageVelocimetry is the combination of PIV with thermometry (PIV/T).

Request for a quote

SUVIS GMBH

Germany

The measurement technique of LaserDopplerVelocimetry (LDV) is one of the most frequently applied modern measurement techniques in fluid mechanics to perform accurate local flow velocity measurements, which exhibits the advantage of a very high local and temporal resolution. Our technical department offers excellent conditions to perform such measurements (LDV).

Request for a quote

SUVIS GMBH

Germany

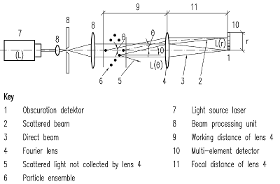

Particle size measurements are important in various applied sciences and in engineering, for example in fuel burning or in cavitation research as well as in particle size control. In all these applications it necessary to have knowledge about the particle dynamics. To gain that knowledge one has to measure the particle size and its velocity if possible in a noninvasive way with high local and temporal resolutions. A device which makes such measurements possible is the so called PhaseDopplerAnemometer (PDA), which has several advantages. First, it exhibits a large dynamic range from micrometer particles up to sizes in the millimetre range. Then it is very precise and no calibration procedure is necessary. Moreover, it is very robust against optical distortions. In the following the working principle of this flow and particle measurement technique will be explained.

Request for a quote

SUVIS GMBH

Germany

For the generation and production of a spray the knowledge of information like the desired droplet size and its distribution is of fundamental importance. In order to characterise a spray correctly, one has to know the droplet size distribution of the droplets, which were generated out of a given liquid. In many applications it is desired to produce very small droplets. For the design and lay out of inhalers for example, it is necessary to achieve droplet sizes not larger than approximately 10 μm to be absorbed by the lungs. When one designs an atomisation nozzle in view of the desired droplet size distribution, one has to make sure via measurements, that the nozzle is really able the produce the expected droplet size distribution within an acceptable uncertainty range. Besides the droplet size distribution, the droplet velocity is an important parameter since it is a measure of the droplet momentum.

Request for a quote

SUVIS GMBH

Germany

In various chemical or physical and technical processes particles of the order of 1 μm up to a few mm in size appear, whose size distribution is decisive or important for the process. There are many technical examples like in food production, pharmacy, process engineering, fuel burning in turbines, motors etc., slurry burning, and cosmetics. The laser diffraction particle sizer is capable to measure a particle size distribution from a collective of particles like a spray and to appropriately process, describe, and present it. The particle material may be solid or liquid in a gas or gas like air bubbles in a liquid. For the measurement it is only important, that the optical properties of the continuous and the dispersed phase are different. The laser diffraction particle sizer offers the advantage of a fast and non invasive measurement in a wide range of particle sizes. Especially in case of sprays or suspensions this method has become a standard measurement tool.

Request for a quoteService Provider

Altchemnitzer Strasse 11

09120 Chemnitz - Germany