WESSEL-UMWELTTECHNIK GMBH

Germany

Manufacturer/ Producer

WESSEL-UMWELTTECHNIK GMBH

Germany

Biological exhaust air cleaning is always required if exhaust air needs to be purified of volatile organic components the socalled VOCs or odorous substances. The demand for biological procedures has increased in recent years. On the one hand, biological exhaust air cleaning does not generate any climaterelevant greenhouse gases. On the other hand, it meets all legal requirements for clean gas values. With over 200 biological exhaust air cleaning processes installed, Wessel has comprehensive practical knowhow and is the technology leader in the field of biological exhaust air cleaning. The biological exhaust air cleaning systems have been continuously optimised and further developed by WesselUmwelttechnik for decades. The modern cleaning systems from WesselUmwelttechnik work efficiently. Thanks to the continuous monitoring of the plant parameters, they require only a minimum of operating effort.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

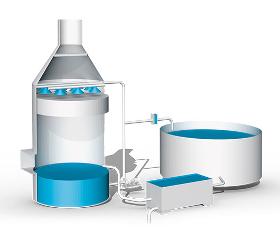

Bio scrubbers are systems for the biological cleaning of exhaust air and exhaust gases and thus for the reduction of odours and polluting emissions. In this process, air polluted with a wide variety of pollutants is cleaned with the aid of a washing liquid which is loaded with microorganisms and biocatalysts (various enzymes) taken from nature. The bio scrubbers from WesselUmwelttechnik work almost without wastewater and are therefore very sustainable, regardless of the nature of the exhaust air. The basic requirement, however, is that the ingredients are watersoluble and bioavailable. WesselUmwelttechnik supplies turnkey plants like the Wessel BIOCATScrubbers in single and multistage construction.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

A bio scrubber combines physical scrubbers with a biological activation unit. In this process, air polluted with a wide variety of pollutants is cleaned with the aid of a washing liquid which is loaded with microorganisms and biocatalysts (various enzymes) taken from nature. The washing water absorbs the exhaust air and pollutants from the air. Subsequently, added microorganisms oxidise them. These microorganisms use the air pollutants as substrate and nutrient medium and convert them into naturally formed decomposition products such as CO2, water, and biomass. Here, the washing water is continuously regenerated and used in a closedcircuit water treatment system. TYPICAL APPLICATION AREAS These plants are primarily used for watersoluble ingredients of the exhaust air. The usual pollutants that are filtered from the exhaust air with the help of bio scrubbers include aldehydes such as formaldehyde, alcohols, ketones and other hydrocarbon compounds.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

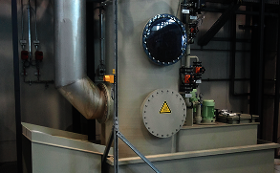

The BIOCATDUOscrubber from WesselUmwelttechnik consists of two units. One unit is the already mentioned BIOCATscrubber. A second unit, the DLP (Dust Low Pressure) scrubber stage, is a cleaning stage for separating dust and fine fibres from the exhaust air. With the BIOCATDUOscrubbers from Wessel, gaseous pollutants as well as dust can be removed from the exhaust air at the same time. The BIOCATDUOscrubbers have two separate washing water circuits for this purpose. It is characterised by a compact design, as both units are housed in one column. COMMON USE CASES The BIOCATDUOscrubbers are used in the woodbased panels industry, for example. More precisely where MDF boards (medium density fibre) and moulded fibre parts are produced. Here the exhaust air contains fine wood fibres which have to be filtered out of the exhaust air. Furthermore, pollutants and odours must also be reduced.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

Biological exhaust air cleaning is used whenever exhaust air has to be cleaned from volatile organic compounds (VOCs) and odours. Biofilters play a major role in this process. The polluted exhaust air is passed through a filter medium where the VOCs and odours are separated. Normally, this medium is an organic carrier material where microorganisms are grown on. They convert the VOCs and odours into noncritical components by means of their metabolism. Especially regarding the removal of odorous substances, biofilters are a very efficient and comparatively inexpensive way of biofiltration with an efficiency of up to 99 %. BIOCATbiofilters have a high degree of efficiency in a wide range of applications, even for exhaust air components that are difficult to dissolve in water.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

When it comes to filter material, there are a few points to consider. The filter material should have a large surface area. This ensures a good exchange rate between exhaust air and filter material and provides sufficient space for microorganisms to colonise. The filter material must be designed in such a way that it has a good water holding capacity. The colonised microorganisms are only viable in a moist environment. In general, different filter materials are used in one batch. The reason for this it ensures both a good stability of the filter bed and a larger surface. In addition, the added microorganisms must be sufficiently supplied with inorganic nutrients and trace elements, unless this is provided by the composition of the exhaust air. The temperature inside the biofilter system plays a decisive role as well. Temperatures between 5 °C and 40 °C are favourable for the microorganisms to work properly.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

Industrial air scrubbers are used to purify the exhaust air of pollutants, for example in the chemical or pharmaceutical industry. As soon as the exhaust air meets the legal requirements for clean gas values, it can be returned to the environment. Absorptive exhaust air purification by waste gas scrubbers is a frequently used technology. Gas scrubbers are suitable for removing pollutants, aerosols and dust from the exhaust air. Especially watersoluble exhaust air components are separated with high efficiency.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

If no procedures for biological or chemical exhaiust air cleaning are to be used efficiently, the thermal treatment is regarded as method of choice. The basic thermal processes are Recuperative thermal oxidation Regenerative thermal oxidation Catalytic oxidation. The focus of our products lies particularly in the periphery of especially challenging special solutions Waste treatment Sewage sludge drying Waste water treatment Landfill aftercare Specialpurpose solutions for the chemical industry Food industry In general at corrosive media, at risk of condensation, and especially high specifications for the pure gas Since 2018 we are working close with our sister company Airprotech Srl. from Magenta/Italy in the field of thermal exhaust air cleaning. Beside our core products our range of products in the field thermal exhaust air cleaning is broadened Airprotech is specialised in the development, the manufacture and the supply of turnkey plants for thermal cleaning

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

In many incineration and industrial plants in various industries as well as in the municipal sector, dust emissions are produced during production processes. These emissions must be purified before they are released into the atmosphere. The dusts can be sticky, greasy, wet, dry or combustible and have different particle sizes. In general, they are between 0,1 and 1000 μm in size. Dust collection systems physically filter these dusts out of the exhaust air. WesselUmwelttechnik specialises in various methods of exhaust air cleaning, including industrial dust collector systems, to safely comply with legal requirements, e.g. the German TA Luft. In addition to dry filtering, the product range includes wet separators. This way, even humid and hot exhaust air as well as agglomerating dusts can be treated by the Wessel systems. The various exhaust air purification technologies allow the use of dust collecting systems in a wide variety of industries.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

In many incineration and industrial plants of various sectors as well as in the municipal sector, dust emissions are produced during production processes. These emissions must be purified before they are released into the atmosphere The resulting dusts can be sticky, wet, dry or combustible and have different particle sizes. Often industrial dusts are between 0.1 and 1000 μm in size and vary greatly in composition. They are also present in various concentrations and combinations with other pollutants. Compared to dry separators, wet scrubbers have the great advantage that fires or explosive mixtures cannot occur. Depending on the industry and area of application, such as in incineration plants, wet separators are indispensable.

Request for a quoteManufacturer/ Producer

Kieler Straße 131

22769 Hamburg - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These screws are produced by automatic turining machine,custom screw fittings are mainly used in small internal parts of machinery.

Request for a quote

TROTEC GMBH

Germany

Reduces pollutants in the room air and increases the quality of lifeThe design air cleaner AirgoClean® 11 E combines timeless elegance with efficient HEPA air purification technology. Thanks to its high-quality matt black surface and the aesthetic cylindrical shape, the compact air cleaner makes a visual statement in both private and professional environments. Without losing sight of what matters most – bringing healthier air into your home for breathing freely. Our own four walls are our protected space for recharging our batteries and enjoying life with every breath. It is where we want to feel comfortable without having to fear that our health is endangered by airborne influences. Clean air is essential for healthy living Every day, we breathe in and out up to 20,000 litres of air. This corresponds to a mass of around 25 kilos and far exceeds the amount of food and drinks consumed per day.

Request for a quote

TROTEC GMBH

Germany

Air purifiers from the TAC series play an important role in keeping the working clean by extracting all hazardous substances. This is a dust class H model and its recommended air volume is 500 m³/h. The optimal design of the air purifier makes it possible to have different filters for different levels of room contamination. Filtration range: Asbestos dust Silica dust Building rubble Flour dust and wood dust Mineral fibre Mould spores Colour particles Typical fields of application: Blasting operations Construction works and restructuring works Water damage restoration Fire damage restoration Mould remediation Asbestos abatement Cleanroom applications

Request for a quote

TROTEC GMBH

Germany

AIR WASHER AW 10 SLow-maintenance 3-in-1 comfort device for air humidification and purification Usually, we spend 80 % of the day indoors, where the room air is often untreated and not ideally adapted to our natural needs. Too dry and dusty air does not only make residents but also the furniture suffer. In contrast, air that is humidified and cleaned on a natural basis is a boon: with the air washer AW 10 S you can breathe freely again and conveniently prevent colds and dry coughs caused by dried-out mucous membranes, as well as damages to furniture, parquet floors or musical instruments caused by too dry air. The AW 10 S is a 3-in-1 combination device – it does not only humidify the air by means of self-regulating cold evaporation, it also washes the air and cleans it of animal hair, house dust and pollen. Before emerging into the room the air is additionally ionised on a natural basis, whereby contaminants are neutralized and odours reduced.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free