- europages

- >

- Conveyor belts

- >

- WIRE BELT COMPANY LTD

- >

- products

WIRE BELT COMPANY LTD - The Trusted Metal Conveyor Belt Manufacturer

United Kingdom

Manufacturer/ Producer

WIRE BELT COMPANY LTD

United Kingdom

C-CureEdge™ C-shaped edge loops help to prevent catching during installation and operation of your conveyor belt especially during tight conveyor-to-conveyor transfers. C-CureEdge™ edge loops also add an extra layer of safety to your belt by minimising the risk of catching during contact. C-CureEdge™ is available on many Flat-Flex®, Flat-Flex® XT®, and comes standard on Compact-Grid® conveyor belts.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

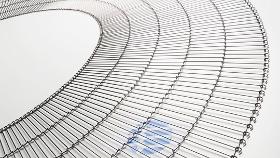

Flex-Turn® conveyor belts gently convey products in process around corners while maintaining proper product alignment and spacing. They offer the tightest level transfer and smallest inside turning radius available. Smooth product handling minimises potential damage to delicate products. Our Flex-Turn® conveyor belts are specifically designed to work with our Flex-Turn® conveyors. Like all of our Flat-Flex® belts, Flex-Turn® belts are easy-to-clean and maintain.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Field-proven and dependable Flex-Turn® units gently convey products in process around corners while maintaining proper product alignment. They offer the tightest level transfer and smallest inside turning radius available with an open mesh belt. Smooth, non-collapsing product handling minimises potential damage to delicate products. The compact design solves tight production line space problems.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Wire Belt offers a range of straight conveyors designed to ensure efficient operation, improved belt life and maximum cleaning ability. Our straight conveyors feature an open construction with the belt being supported on food grade high density blue polyethylene wear strips clipped to the stainless steel framework. All of our conveyors are suitable for use in hygiene-sensitive environments common to the food and pharmaceutical industries.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

When looking for the best conveyor belt drive components for your machine, look no further than Wire Belt’s customised sprockets and blanks. We can guarantee the perfect fit to keep your lines running smoothly and efficiently. Whatever drive component you may be looking for, we offer a variety of materials to meet your needs. To find out more about our solutions, contact our Technical Sales Engineers.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Wire Belt introduces our line of PEEK drive components. PEEK is an abbreviation for PolyEtherEther-Ketone, a high performance engineering thermoplastic that can operate at high temperatures and is less abrasive on your stainless steel belts than metal drive components. PEEK can be used continuously to 240°C and in hot water or steam without permanent loss in physical properties. Our PEEK line is available for all Flat-Flex®, Versa-Link™, and Compact-Grid™ drive components including: sprockets, blanks and end rollers.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Wire Belt’s innovative line of Clean-Sweep™ sprockets are specifically designed to deflect the amount of product buildup accumulated on your conveyor’s drive. This means that there is less of a chance for product loss & carryout, belt skipping due to product buildup, and belt breakage due to incorrect contact with the sprocket teeth. Clean-Sweep™ sprocket’s tooth chamfer is machined to reduce drive friction and can lengthen belt life.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Using EZ-Splice™ belt joining strand during installation will dramatically extend your belt life! Belt installations that are rushed and improperly made are often the cause of belt breakage and downtime. EZ-Splice™ is a pre-formed, pre-bent joining strand that requires no bending or weaving during installation. This helps to prevent any weak spots in the belt joint.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Joining tubes can be used to create a hybrid join between a full strand weave and the use of joining clips. A single strand is cut into smaller single space sections, which are woven into the belt and joined together by crimping a stainless steel joining tube onto the adjacent wire sections. This method maintains the belt strength of a full strand weave while eliminating the distortion that occurs during the weaving process. It is important to consider whether joining tubes could mark product or have hygiene implications when choosing this method.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Conveyor Belt clips are used for joining the belt during installation and for making fast minor repairs to the belt. They are available in one space and three space units. If you would like clips, these should be ordered at the same time you place your belt order.

Request for a quoteManufacturer/ Producer

Castle Road, Eurolink Industrial Estate,

ME10 3RF Sittingbourne - United Kingdom