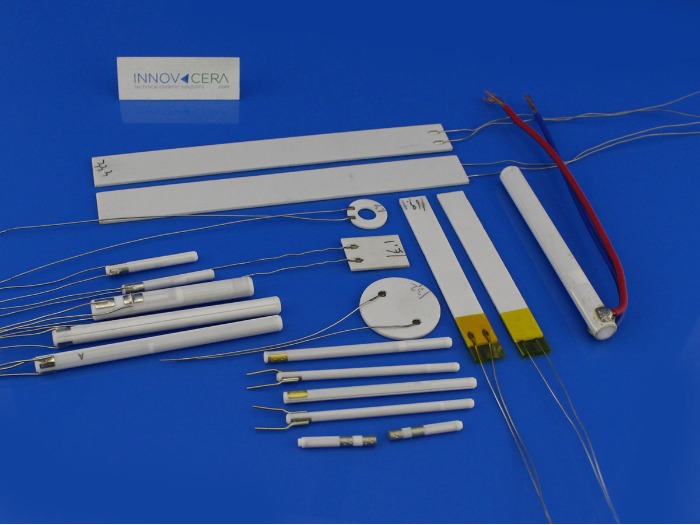

What is MCH heater? MCH heater is the abbreviation of metal ceramic heaters.It refers to a ceramic heating element in which a meta tungsten or molybdenum manganese paste is printed on a ceramic casting body and laminated by hot pressing and then co-fired at 1600°C, in a hydrogen atmosphere to co-sinter ceramic and metal. 2.What is the advantages of MCH heater? MCH ceramic heating element is high-efficiency, environmentally friendly, and energy-saving. ceramic heating element, which is mainly used to replace the most widely used alloy wire heating elements and PTC heating elements and components. Technical characteristics: Energy-saving, high thermal efficiency, unit heat power consumption is 20-30% less than PTC; The surface is safe and non-harged, with good insulation performance, can withstand the withstand voltage test of 4500V/1S, no breakdown, and leakage current <0.5mA; No impulse peak current; no power attenuation; rapid heating; safe, no open flame;