- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- 24 hour service

Results for

24 hour service - Import export

BORSIG GMBH

Germany

BORSIG offers comprehensive services for the power engineering, chemical and petrochemical industries as well as oil, gas and water supply. From our facilities Berlin, Gladbeck and Hamburg our exellently networked global team of engineers and technicians provide you with competent, fast and reliable support. We have decades of experience in planning, performing and implementing all kinds of assembly, manufacturing and service tasks. We rectify malfunctions and procure any required spare parts. We support you in the planning, delivery and installation of new components in your systems, modification, inspection and maintenance of existing components provided by us or third parties, and we also offer troubleshooting within the framework of a 24-hour standby service. Our services comprise: - Pressure vessels: Field service and repairs - Engineering - Boiler service - Piping - Workshop facilities for new production and overhaul of vessels

Request for a quote

MAINTENANCE PARTNERS

Belgium

The service range that we provide for reciprocating compressors allow you to benefit from the expertise and skills developed by our workshops and field service teams. 24 – hour service Repairs Engineering Compressor Audits Parts supply Field service Relocations Full general overhauls Maintenance Contracts Condition monitoring Used machinery Technical consultancy WORKSHOP ACTIVITIES Complete overhauls of reciprocating compressors Cylinder liner replacements Bearing repairs Crankshaft repairs Pistonrod repairs by HVOF spraying Crosshead repairs Conrod repairs Parts supply by reverse engineering or supplied by OEM Valves & stuffingboxes overhauls ENGINEERING Upgrades Re-rating Piston rod drop system Hydrocom system FIELD SERVICE Minor and Major overhauls of reciprocating compressors Provision of Supervisors, technicians and mechanics required to perform the activities Turnkey jobs Toolcontainers Troubleshooting Emergency interventions

Request for a quote

MAINTENANCE PARTNERS

Belgium

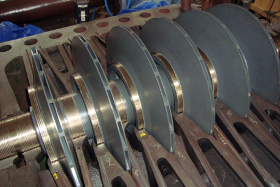

Maintenance Partners is the one-stop-shop for steam turbine maintenance. We have all the expertise needed for complete overhauls, repairs, reconditioning, upgrades, revamps and relocations of steam turbines, regardless of type or make. Our rotorshop performs all aspects of rotor, diaphragm & blade carrier repairs, ranging from NDT inspections to high speed balancing. Steam Turbine Maintenance – Service packages The range of service we provide allows you to benefit from the expertise and skills developed by the workshops and field service teams. 24 – hour service Upgrades Full general overhauls Relocations Repairs Service agreements Engineering Partnership agreements Parts supply Condition monitoring Field service Used machinery Re-rates & de-rates Technical consultancy Workshop activities Complete overhauls Rotor repairs Rotor repairs by welding Straightening of bent rotors Re-blading Parts supply by reverse engineering or supplied by OEM

Request for a quote

MAINTENANCE PARTNERS

Belgium

P RODUCT RANGE FOR TURBO / CENTRIFUGAL COMPRESSORS Maintenance Partners is your partner for complete overhauls, repairs, reconditioning, upgrades, revamps and relocations of turbo compressors, both on site as well as in one of our workshops. Axial compressors Radial compressors – splitline and barrel type Screw compressors Bull gear type compressors ATLAS COPCO – BORSIG – DRESSER RAND – DEMAG – ELLIOTT – HITACHI – HOWDEN – KOBE – MAN TURBO – MITSUBISHI – NUOVO PIGNONE – SIEMENS – STORK DELAVAL – SULZER – THOMASSEN SERVICE PACKAGES The range of services that we provide for centrifugal compressors allow you to benefit from the expertise and skills developed by the workshops and field service teams. 24 – hour service Full general overhauls Repairs Engineering Parts supply Field service Re-rates & de-rates Upgrades Relocations Service agreements Partnership agreements Condition monitoring Used machinery Technical consultancy WORKSHOP ACTIVITIES Complete overhauls of turbo...

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners is your partner for complete overhauls, repairs, reconditioning, upgrades, revamps and relocations of turbo compressors, both on site as well as in one of our workshops. Axial compressors Radial compressors – splitline and barrel type Screw compressors Bull gear type compressors SERVICE PACKAGES The range of services that we provide for centrifugal compressors allow you to benefit from the expertise and skills developed by the workshops and field service teams. 24 – hour service Full general overhauls Repairs Engineering Parts supply Field service Re-rates & de-rates Upgrades Relocations Service agreements Partnership agreements Condition monitoring Used machinery Technical consultancy WORKSHOP ACTIVITIES Complete overhauls of turbo compressors Rotor repairs Repairs of impeller and diaphragm vanes Parts supply by reverse engineering or supplied by OEM Low speed balancing High speed balancing Impeller spin test

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LLOYD DYNAMOWERKE GMBH

Germany

From the project planning stage through to the end of their operating life we offer a range of concepts for economical and fault-free operation of your machines Target-oriented maintenance intervals to match the respective operating conditions Online and offline status monitoring Trend measurements relating to wear behaviour of the mechanical and electrical components Stocking spare parts for shorter downtimes Training for maintenance staff 24 hour service Company-oriented maintenance contracts Modernisation of the machine, controllers and protection equipment Environmentally compatible recyclingTesting of electrical machines and systems, type tests, system tests, heat run tests according to DIN standards Dynamic balancing or rotors Cleaning and oven drying of large machine parts such as stators or rotors VPI impregnation with rotating hardening process in drying oven VPI impregnation of transformers and large coils VPI or resin-rich coil production Manufacture of tooth-wound coils

Request for a quote

AQI SERVICE - CHINA INSPECTION SERVICES AND QUALITY CONTROL IN ASIA

China

The Pre-Production Inspection (PPI) service includes visiting the manufacturer prior to the commencement of production or the first batch of products to examine the quality of all raw materials and do first products inspection and confirm that all manufacturing processes adhere to the requirements of our client. Our professional quality engineer will help to solve any problems immediately to ensure a smoothly running production and the inspection report with full information will be emailed to you within 24 hours The pre-production inspection service (PPI) will include your interests as below but not list all: Verifying the production and quality plan Inspecting the packing way and related labels Inspecting the storage way of your products Inspecting workmanship appearance Inspecting function, size and measurement Making the reliability and safety tests Other specified requirements from you

Request for a quote

KARDEX DEUTSCHLAND GMBH

Germany

For efficient slow-moving parts management, it is essential that the items can be accessed quickly and the space needed to store a wide range of products is kept as small as possible. Kardex Remstar has the right answer here, because the high order picking performance of the Kardex Remstar LR 35 makes it the ideal solution for the highly dense storage and retrieval of goods with low turnover frequency. The Kardex Remstar LR 35 is especially ideal for medium-sized businesses and wholesalers with comprehensive 24-hour service and overnight delivery, because the high order picking performance of up to 500 order lines per picking station and hour minimizes processing times for the wide range of slow-moving parts kept in stock. In addition, direct delivery of the goods to the workstation reduces waiting times and the distance covered by the operating personnel, while also cutting the number of employees needed. Performance is further increased by processing the orders using the batch-pick

LEVANT RUS LLC

Russia

High-quality construction made entirely of stainless steel, heat exchanger made of heat-resistant stainless steel AISI 310S rotary platform drive without frame two independent steam generators - a tray in the hot air stream and a high-temperature one, built into the heat exchanger and heated by exhaust gases highly efficient heat block with air movement from the least hot output stage to the hottest zone of the furnace thermal insulation with a thickness of 150 mm 3 years warranty, 24-hour customer service the height of the baking chamber in the serial version is 2000 mm, an increase in productivity by 22% with the same occupied area two circulation fans, air supply from both sides – a large volume of heated air at low speed reduced baking time, reduced baking loss thermal efficiency is more than 93%, which is the best indicator best price-quality ratio, the minimum payback period.

Request for a quote

LEVANT RUS LLC

Russia

Lewant Eco 800 High-quality construction made entirely of stainless steel, heat exchanger made of heat-resistant stainless steel AISI 310S rotary platform drive without frame two independent steam generators - a tray in the hot air stream and a high-temperature one, built into the heat exchanger and heated by exhaust gases highly efficient heat block with air movement from the least hot output stage to the hottest zone of the furnace thermal insulation with a thickness of 150 mm 3 years warranty, 24-hour customer service the height of the baking chamber in the serial version is 2000 mm, an increase in productivity by 22% with the same occupied area two circulation fans, air supply from both sides – a large volume of heated air at low speed reduced baking time, reduced baking loss thermal efficiency is more than 93%, which is the best indicator best price-quality ratio, the minimum payback period.

Request for a quote

LEVANT RUS LLC

Russia

Lewant Eco 600 High-quality construction made entirely of stainless steel, heat exchanger made of heat-resistant stainless steel AISI 310S rotary platform drive without frame two independent steam generators - a tray in the hot air stream and a high-temperature one, built into the heat exchanger and heated by exhaust gases highly efficient heat block with air movement from the least hot output stage to the hottest zone of the furnace thermal insulation with a thickness of 150 mm 3 years warranty, 24-hour customer service the height of the baking chamber in the serial version is 2000 mm, an increase in productivity by 22% with the same occupied area two circulation fans, air supply from both sides – a large volume of heated air at low speed reduced baking time, reduced baking loss thermal efficiency is more than 93%, which is the best indicator best price-quality ratio, the minimum payback period.

Request for a quoteResults for

24 hour service - Import exportNumber of results

12 ProductsCountries

Company type