- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- angle control valve

Results for

Angle control valve - Import export

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat control valve type 7025 with integrated digital positioner is specially adapted for use in the food and beverages production. Suitable for controlling product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Compact right angle motor valve made from stainless steel for on/off and control operation, ideal for installations where space is limited and for use with neutral and aggressive media. The valve is a perfect alternative to pneumatic valves if compressed air is unavailable, on request with failsafe option. Whitworth pipe thread NPT thread Positioner electronics, limit switch, position feedback All control actuators are also available with fail safe feature. Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatic control valve with angle seat design. The angle seat design offers a high flow capacity, the flange connection an easy installation. The integrated digital or analogue positioner is coming along with a very compact design. All wetted parts are made from stainless steel. Flange acc. to DIN EN 10921 Flange acc. to ANSI #150, ANSI#300 Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof versionPiston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatic control valve with angle seat design. The integrated positioner type 8049 means that a compact design is achieved. All parts that come into contact with the medium are made from stainless steel. Whitworth pipe thread NPT thread Welding ends Triclamp connection Special connections Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof version Piston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatic right angle control valve with integrated positioner for high cycle applications and compact installations. Due to the stainless steel design suitable for neutral and aggressive media but also for a wide range of temperature applications. Whitworth pipe thread NPT thread Whitworth pipe thread NPT thread Piston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Degreased version, Silicon or PTFEfree version …

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 507 2/2-way angle seat globe valve has an ergonomically designed plastic handwheel and is manually operated. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. A stainless steel bellows and a handwheel extension are available as options (not for operator size 0). —Various valve body connections (threaded sockets, threaded spigots, butt weld spigots) available —High flow rates due to angle seat design —Optionally for contact with foodstuffs as per directive (EC) No. 1935/20041 (K-no. 1935)

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 549 2/2-way angle seat globe valve has a hollow shaft actuator and is electrically operated. The eSyDrive hollow shaft actuator can be operated as an OPEN/CLOSE actuator or as an actuator with integrated positioner or process controller. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. An integral optical and electrical position indicator is standard. — Linear or modified equal-percentage control characteristics — High flow rates — Force and speed are variably adjustable — Extensive diagnostic facilities — Operable via web interface eSy-Web — Integral optical position indicator and LED high visibility display — Standard gland packing suitable for vacuum up to 20 mbar (abs.)

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

High Pressure Control Valve is designed and developed for applications where the high pressure / drop liquid and high pressure / temperature gas/vapour to be handled. Our specially designed Velocity Control Trim, which is a multi turn / multistage velocity control trim, handles these severe/critical applications very effectively – eliminating cavitation & vibration, and reducing the noise to the acceptable levels.

Request for a quote

PNEUFLEX PNEUMATIC CO., LTD

China

Pneuflex flow control valves (speed controllers | pneumatic fittings) capable of adjusting the flow rate of compressed air. The speed controller bodies can be rotated after installation to allow for variations in piping direction. Composite right angle flow control-out valves (pneumatic fittings - meter-out speed controllers ) adjust the speed of air flow from thread to tubing. Composite right angle flow control-in valves (pneumatic fittings- meter-in speed controllers) adjust the speed of air flow from tubing to thread. Speed controllers accommodate metric tubing O.D ranging from 4mm to 16mm. inch tube 1/8" to 1/2", and accommodate inch tubing O.D ranging from 1/8" to 1/2". BSPT Thread sizes ranges from BSPT1/8 to BSPT1/2, NPT thread ranges from 1/8 NPT to 1/2 NPT..

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Brake force control valve for stepless regulation of the brake pressure.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALPECO LTD

United Kingdom

Alpeco is the UK distributor of OCV control valves. These valves can be found in Waterworks, Fire Protection, Irrigation, Industrial, Petroleum and Aviation fueling in nearly every country throughout the world. The range of models available is extensive and includes pump control valves, pressure relief and safety valves, high level shut-off valves and flow control valves.

Request for a quote

TETHYS OIL SUPPLIES & SERVICES

Malta

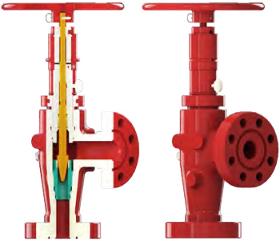

The 200 Series choke valves are the result of our continued commitment to product research and development in the oil and gas industry. We have a proven track record of delivering technical solutions for our customer base stretching back decades. The 200 Series has evolved from years of product experience and incorporates the latest in material and manufacturing techniques. Each choke valve is designed, manufactured and tested in accordance with API 6A and can be fabricated to various material classes and product specification level. A wide variety of product configurations are available to meet every client need.

Request for a quote

MÜLLER CO-AX GMBH

Germany

This series comprises valves with two connections that are operated by an electric motor. They are characterized by the fact that the valve stroke can be adjusted steplessly and held in place by a motor using a setpoint signal (420 mA or 010 V). This makes this series particularly suitable for precise dosing applications, as the servo motor reliably processes setpoint deviations of 1%.

Request for a quote

MÜLLER CO-AX GMBH

Germany

Within the family of pressureregulating valves, a technical distinction is made between series of bypass valves, inline valves and threeway valves.

Request for a quote

ALPECO LIMITED

United Kingdom

Flow control valves regulate the flow or pressure of a fluid. Control valves normally respond to signals generated by independent devices such as flow meters or temperature gauges. Alpeco stock a range of Perrett hydrovalves and is the UK distributor for OCV Control Valves, who are leaders in control valves, check valves and pressure relief valves. Our flow control valves can be used across a wide range of fluids from fuel, oil and lubricants to paints, chemicals, water and cement.

Request for a quote

HYDROSILA

Ukraine

Directional control valves series MRS120 are universal control valves of a wide application. Control valves series MRS120 are intended for use on excavators, cranes, loaders, trucks, drilling machines and other equipment. The auxiliary valves (anticavitation, shockproof, combined) are available.

Request for a quote

EM-TECHNIK GMBH

Germany

The electrical fine control valve makes it possible to adjust volume flows precisely via an input signal (4-20 mA) and to approach an exact spindle position. The valve can also be controlled by a 24V continuous voltage. Position feedback is implemented by a 4-20 mA output signal. With an additional adapter, the valve can also be connected via an RS-232 interface to a computer. The valves are available in 1/4" (10-200 l/h of water) and 1/2" (50-500 l/h of water).

Request for a quoteResults for

Angle control valve - Import exportNumber of results

25 ProductsCompany type

Category

- Electric motors and parts (7)

- Valves for industrial fittings (5)

- Valves for pneumatic equipment (5)

- Plumbing, industrial (2)

- Construction - Machines & Equipment (1)

- Industrial valves, operating equipment (1)

- Oil - drilling and extraction (1)

- Plastics - industrial machinery and equipment (1)

- Steam turbines (1)

- Ultrasonic measuring equipment (1)