- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic positioning systems

Results for

Automatic positioning systems - Import export

SHANGHAI DURA INDUSTRIAL CO., LTD.

China

Our factory produce automatic and semi automatic bobbin winding machine, this is automatic type 2 position PLC control system bobbin winding machine can be used to wind the different size bobbin automatically. One time wind two bobbins and no need worker to change the bobbin after the bobbin winded full. Specification: Model: DR-2 1, Two heads; high speed of 3200RPM 2, Advanced design with space saving and easy operation 3, Highly automatic to save labor 4, Auto-stop for yarn breaking and auto-counting 5, Suitable for all high speed bobbins and some low speed ones. 6. Voltage: 220/380 VAC, 50/60HZ 7. Power: 0.75kw Quality Control: All the machines will be inspected carefully before delivery. Oversea service: We have agent in different countries, so oversea service is available. Certificate: CE Packing: The quantity under 10 sets packed in single wooden case, over 10 sets order will load in full container.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

One machine can make three bag types: Quad seal bag, pillow bag, and gusseted bag. Optional device: Euro slot hole punching device (make a hole on the top of bag), Nitrogen filling device Features 1. Imported plc full computer control system, full Chinese/English touch screen operating system, clear display of the working status and instructions 2. High Precision servo film system, smooth movement of the film, with photoelectric automatic positioning and tracking system, accurate positioning 3. Intelligent digital temperature control system, temperature-controlled stability, with teeth-shaped sealer, sealed firmly 4. Including automatic fault alarm display function, such as low temperature, no packaging film, colorless belt, no material, servo failure, colorless signal, glass protection door when opened automatically alarm or shutdown function 5. This machine and metering device can be completed automatically by metering, feeding, filling bag, date printing, and finished.

LVD

Belgium

TL 8525 is a high-capacity tube laser cutting machine designed for top productivity. It handles lengths up to 8500 mm and diameters up to 250 mm round or square. The TL 8525 comes equipped with leading-edge features, including a 45-degree tilt-axis cutting head with NC-Focus, 6-position front loader, 2 kW IPG fiber laser, and a large X-axis cutting head range of 1190 mm to maximize material usage. KEY FEATURES Accommodates tube and profile lengths up to 8500 mm, diameters up to 250 mm High-performance cutting head with NC-Focus and bevel function +/- 45 degrees Magazine style 6-position automatic tube load system Leading edge detection for variable tube lengths Automatic bow detection and compensation system Automatic twist compensation system Outfeed tube support with accompanying conveyor table Siemens CNC control is PC-based with touchscreen PERFORMANCE-ENHANCING OPTIONS 4 kW fiber laser source 6100 mm outfeed extension Part evacuation conveyor Automatic weld seam detection

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Highlights: Very fast “Time to Market” for new stamped and formed parts made of wire and strip as well as progressive components •Quick feasibility statements and precise quotations (“Bihlerplanning” WebApp, defined process limits) •Simple and structured design methodology of bNX software (WebApp for design support, templates) •Very short tool production times (high proportion of standard machine and tool parts) •Up to 70% lower manufacturing costs compared to conventional forming tools •Extremely fast, 100% reproducible setup operations (automatic slide positioning, quick clamping systems, data retrieval from VC 1 control system) •Lower logistics and maintenance costs

Request for a quote

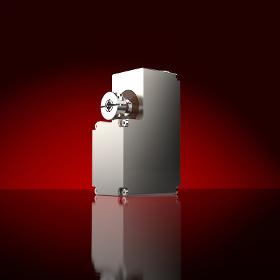

HALSTRUP-WALCHER GMBH

Germany

The PSE 21x/23x-8 positioning systems are compact solutions with integrated intelligence that frees up the machine´s central control unit. The intelligent positioning system automatically adjusts auxiliary and positioning axes using a DC-motor, gear, controller, measuring system and CANopen, DeviceNet or Modbus RTU interface. No external motors, proximity or limit switches are required. The absolute measuring system at 64 revolutions (optional) eliminates the need for time-consuming reference runs and increases the efficiency of the machine. The economical motor also makes the system suitable for automation jobs that were previously uneconomic due to the cost. The separated supply voltages for the control and performance electronics provides an emergency shut-off function without interrupting communication with the control module. Address and baud rate switches (optional) simplify start-up, even without the knowledge of the control software.

Request for a quote

ILK IHRACAT AS.

Turkey

For companies seeking the ultimate in automation and efficiency, fully automated loading and unloading systems are the answer. These systems utilize advanced technology, such as robotics and computerized controls, to handle the entire loading and unloading process without human intervention. Goods are automatically sorted, transported, and loaded onto trucks, eliminating the need for manual labor entirely. Fully automated systems are ideal for high-volume operations where speed, accuracy, and consistency are paramount. In conclusion, automatic loading and unloading systems offer numerous benefits for companies in the transportation industry. Whether it’s conveyor systems, hydraulic lift gates, pallet jacks, or fully automated systems, these technologies enhance productivity, improve safety, and streamline operations. By implementing these systems, companies can reduce labor costs, minimize the risk of injuries, and increase overall efficiency.

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive for installation situations with little space • Monitoring of important system parameters ensures reliable operation (overload protection) • Ready for use immediately after power on due to absolute multiturn position detection • Maintenancefree due to sealedforlife lubrication • Optionally with cULus component recognition

Request for a quote

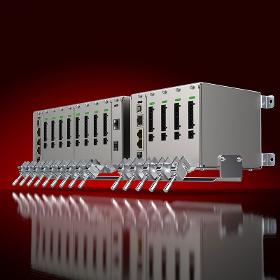

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Interface for controlling up to 5 positioning drives • Integrated power management • Straightforward commissioning of the SeGMoPositioning • Depending on the design either with cULus component recognition or cULus listing • Support Tool for advanced commissioning and configuration

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive with through hollow shaft • Batteryfree multiturn absolute encoder • Aluminium housing • Optionally with cULus component recognition

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive suitable for a wide range of applications in various industrial areas • Batteryfree multiturn absolute encoder • High dynamics • Optional use with the SeGMoBox or as a standalone device • Optionally with cULus component recognition

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Intelligent connection box in modular design • Two housing variants with 4/9 slots available • Module combination for control of up to 17 axes • Conveniently configurable via SeGMoSupport Tool

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Conventional thermometers measure the temperature by means of length or volume change of a material, and are only suitable as display instrument. Temperature sensors from Lenord+Bauer use resistance thermometers that feature an almost temperaturelinear r

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Fast and controlled format changes thanks to the intuitive SeGMoAssist compact nominal value display from Lenord+Bauer, that's now possible even in plants without fully automated adjustment. • Display supports the operator, e.g. during format or tool changes • Bright graphical display • Presentation of customerspecific pictograms • Insensitive to EMC interference • Maintenancefree

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Fast and controlled format changes thanks to the intuitive SeGMoAssist digital position display from Lenord+Bauer, that's now possible even in plants without fully automated adjustment. • For guided format adjustment • Display of nominal and actual position to facilitate manual adjustment processes • Bright graphical display • Presentation of customerspecific pictograms • Optional for rotatory and linear position measurement • Insensitive to EMC interference • Ready for use immediately after power on due to absolute multiturn position detection • Maintenancefree

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

The fully ULcertified positioning system from Lenord+Bauer consists of three individual elements that can be flexibly combined as required positioning drives by the name of SeGMo, the decentralised SeGMoBox control unit for flexible fieldbus integration and the associated hybrid cable solution, including connectors, that is suitable for use with drag chains. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. Lenord+Bauer also offers these for standalone use. With nominal torques of up to 15 Nm, they cover the capacity range typical for secondary axes. Integrate the drives directly into your control system with the function blocks. Alternatively, you can automate up to 17 secondary axes using the decentral SeGMoBox. The box handles the power management for the connected drives and concentrates the interaction with the system control.

Request for a quote

CHANGSHA PANRAN COMMERCE AND TRADE CO., LTD

China

The system consists of computer, PR231 or PR233 calibrator, printer, etc. The secondary instrument input types that can be calibrated include K, N, E, J, T, S, R, B, EA-2 thermocouples, Pt100, Pt10 , Cu100, Cu50 thermal resistance, 0-10V, 1-5V, 0-10mA, 4-20mA, 0-2mV, 0-5mV, 0-10mV and so on.

Request for a quote

IBERSELEX S.A.

Spain

CASHMATIC es una herramienta muy útil para los puntos de venta al eliminar el contacto con el efectivo. Sus principales ventajas son la seguridad y la trazabilidad del efectivo. Con CASHMATIC uno puedo protegerse del robo gracias a su caja de acero, 3 juegos de llaves y sistema de anclaje, pero sobre todo de la perdida desconocida generada diariamente. La implementación de la maquina proporciona control y trazabilidad del efectivo gracias a las alertas y alarmas personalizadas y el registro de todas las operaciones bajo los usuarios habilitados La instalación de CASHMATIC es muy sencilla y se puede hacer perfectamente incluso si el punto de venta del cliente es muy restringido por el fabricante. CASHMATIC posee la patente sobre su “Driver Universal” haciendo posible la instalación en cualquier equipo con Windows 3 modelos: 1. Self-pay 360 : hasta 3 operaciones por minuto 2. Self-pay 660 : hasta 6 operaciones por minuto 3.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Automatic positioning systems - Import exportNumber of results

17 ProductsCountries

Company type

Category

- Driveshafts and micro-motors - electric (9)

- Automatic payment and cash handling systems (1)

- Goods lifts (1)

- Laser - cutting and welding machines (1)

- Machine tools, metal machining - parts and accessories (1)

- Packing and packaging - machinery and equipment (1)

- Servomechanisms (1)

- Textiles - Machines & Equipment (1)