- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic tool changers

Results for

Automatic tool changers - Import export

THOMSON MACHINERY BV

Netherlands

1. The Thomson adopts advanced DSP system with USB connection, operated with handle, convenient operation.2. The whole machine is welded with seamless steel structure, which is high temperature annealing and vibrating stress relief, so the machine body is stabilized and will not be deformed forever.3. The ATC CNC adopts domestic top brand stepper motor to ensure high precision.4. Operating system has friendly easy operation interface, english suggestion and simple setting method.5. Spindle System is divided into single axial and biaxial.6. Transmission system adopts Hiwin square rail and ball screw to control the linear error effectively .7. One-time tool setting to finish the whole workpiece.8. Compatible with several CAD/CAM design software such as Type3, Artcam, etc.9. The ATC wood lathe can completely work offline and do not take any computer resources.10. 4th axis for 3D carving and cutting.11. Automatic tool changer system.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine with rotary indexing table and tool magazine. Automatic tool changer with HSK spindle tools. Mosts common tools used are tampico and sisal fibre brushes for bottom, bottom radius and side wall polishing.

Request for a quote

THOMSON MACHINERY BV

Netherlands

1. 9KW air-cooling ATC spindle motor: Long working life, easy maintenance (HSD brand from Italy for option).2. Taiwan Delta Inverter: Guarantee the variety working speed and protect the spindle very well.3. Big steel square tube structure,by seamless welding and hardening treatment, guarantee it to be strong, reliable and durable, with large bearing capacity and long working life.4. Japan Yaskawa driving System with Shimpo reducer: With highly control precision and high speed, reliable and stable.5. Helical rack and pinion: quiet running, greater accuracy, smoother cutting and allows greater accelaration and feeding rates, longer lifetime because of smaller wearing force.6. High precision Taiwan TBI ball screw and Taiwan Hiwin linear square rails, which move smoothly to ensure the machining precision.7. Disc tool magazine, with Tool holders 12pcs, effectively improve working efficiency.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

PERFECTLY EQUIPPED FOR EVERY TASK! - The TFZ series offers intelligent solutions from A to Z. STABILITY AND HIGHEST PRECISION DO NOT COME FROM ABOUT BY CHANCE. - Static and dynamic optimization of the components in the power flow - Permanent dimensional accuracy and prevention of tolerance overlap - Minimum distance between pivot bearing and tool center point (TCP) WE KNOW WHAT IS IMPORTANT WHEN IT COMES TO OPERATION AND MAINTENANCE. - Easy crane loading thanks to simultaneous opening of the front and roof doors - Generous sliding doors to the work area - Additional viewing window - Tool magazine & tool rack arranged internally for quick changeover | optional: external & automatic tool changer - User-friendly service access TRUST IS GOOD, CONTROL IS BETTER! - Guarantee of professional machining, long tool life and prevention of accidents & breakdowns - Precise process monitoring during machining

Request for a quote

STARRAG GMBH

Germany

The Bumotec s191V is the combination of proven Swiss made mechanics and stateoftheart CNC control and drive technology. With the CNC Bumotec s191V mill / turn center, precise and complex components can be produced via 5axis machining. Thanks to its stable mechanical concept and its linear drive technology, accuracies of just a few microns can be achieved. The integration of an individually adaptable automatic workpiece change unit, allows the machine to be used for one off prototypes or to run so called «unmanned shifts» without personnel. Many different configurations are available with three to five axes of machining capacity. The thermal stabilization unit almost eliminates warmup cycles when starting or after machining interruptions. Features Linear driven motors and directdriven rotation axis High speed spindles (maximum 40,000 rpm) Smart combination of turning and 5axis machining High thermal stability Automatic tool changer for 90 HSK40 tools

Request for a quote

MECANUMERIC

France

The rigour and the accuracy for the industrial works, the polyvalence and the simplicity for a maximum of profitability. Designed for the accurate and intensive works, they allow a wide field of applications : metal engraving, fine millings, design, prototyping Refer to the exemples of applications : Moulds and models Health case or box Side windows Aircraft interior furnishing Jewels engraving Masks Household appliances Lights Furniture Aluminium frames The strengths • XYZ stroke 310 x 430 x 120 mm (DMC300) - "Y" reduced to 250 mm in case of automatic tool changer. • XYZ stroke 600 x 610 x 120 mm (DMC600) - "Y" reduced to 420 mm in case of automatic tool changer. • Rigid structure made of steel / Aluminium foundry. • Double guiding by prismatic rails in grinded steel with re-circulating ball bearings. • Ball screw with pre-stressed sockets. • Cinematics fixed table / mobile gantry. • Available in « servo-brushless » motorization. • Economical version with stepper...

Request for a quote

MECANUMERIC

France

Automatic static or rotative tool changer and cutting tool measurement sensor. Possibility of housing with automatic opening/closing. Subject to the machine configuration / chosen options. Online sales on Meca-line site here

Request for a quote

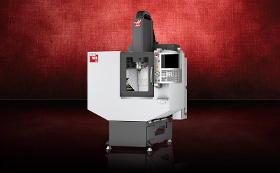

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Compact Mill; 12" x 10" x 12" (305 x 254 x 305 mm), ISO 20 taper, 5 hp (3.7 kW) vector drive, 30,000 rpm, 20-station automatic tool changer, coolant pump, high-speed machining, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor, and USB port CM-1 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Gantry Router; 145" x 85" x 11" (3683 x 2159 x 279 mm), 40 taper, 15 hp (11.2 kW) vector drive, 8100 rpm, 10-pocket automatic tool changer, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port. GR-712 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Gantry Router; 121" x 61" x 11" (3073 x 1549 x 279 mm), 40 taper, 15 hp (11.2 kW) vector drive, 8100 rpm, 10-pocket automatic tool changer, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port. GR-510 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, 10-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port. MINIMILL Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 20" x 16" x 14" (508 x 406 x 356 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, 20-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, 15" color LCD monitor, memory lock keyswitch, USB port and work light. MINIMILL2 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Wireless signal transmission The signals are transmitted from wireless touch probes to the SE transmitter/receiver unit via • radio or infrared for the TS 460, • infrared for the TS 444, TS 642, TS 740. This makes these touch probes ideal for use on machines with automatic tool changers. The following transmitter/receiver units are available: • SE 660 for radio and infrared transmission; shared SE for TS 460 and TT 460 • SE 540 only for infrared transmission, for integration in the spindle head • SE 642 only for infrared transmission, shared SE for TS and TT The SE 660 communicates with the TS 460 and TT 460. The SE 540 and SE 642 can be used in any combination with the TS 4xx, TS 642 and TS 740 touch probes.

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Toolroom Mill with Tool Changer; 40" x 20" x 16" (1016 x 508 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, full enclosure, 10-station automatic tool changer, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-3P Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

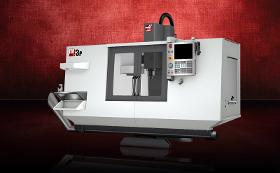

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Toolroom Mill with Tool Changer; 40" x 16" x 16" (1016 x 406 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, full enclosure, 10-station automatic tool changer, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-2P Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

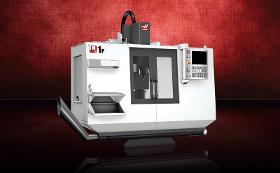

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Toolroom Mill with Tool Changer; 30" x 12" x 16" (762 x 305 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, full enclosure, 10-station automatic tool changer, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-1P Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 15 hp (11.2 kW) vector drive, 10,000 rpm, 1200 ipm (30.5 m/min) rapids, high-speed 10-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, and rigid tapping. Three-phase power only. SMINIMILL Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The smartLine covers the entire spectrum of travelling table grinding machines. From simple reciprocation surface grinding through speed-stroke, slot and profile grinding all the way to creep-feed grinding. This machine concept solves every grinding task. The machine‘s versatile building block system is designed to allow almost any combination in table drive systems from belt drive to ball screw system in combination with table mounted and overhead dressing units to solve your specific grinding task. The Kombi-version of the smartLine allows individual configurations all the way up to a complex creep-feed grinding machine. Grinding width, grinding height, type of drive and spindle power as well as all variations of dressing units from simple table-mounted dressing diamond to CD-grinding with a headmounted roll dressing unit as well as an automatic tool changer for grinding wheels and dressing tools can be selected to meet specific requirements.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The microCut model was specifically designed to meet the requirements of profile and creep-feed grinding applications. The modular column design offers a small footprint which can be easily configured into economical production cells frequently used in the turbine manufacturing industry. This machine is available in compact standard sizes but special designs with spindle power up to 52 kW are also available. The integration into production lines is achieved through automatic material handling and tool changers. A common solution to reduce non-productive time is to equip the microCut with an index table to allow loading and unloading during the machining cycle. For high-precision applications, dressing of the grinding wheel can be done on the table with a diamond roll dressing unit or via interpolation of feed and cross axes. For production grinding the overhead diamond roll dressing unit is used for CDCF or intermitten dressing.

Request for a quoteResults for

Automatic tool changers - Import exportNumber of results

20 Products