- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation solutions

Results for

Automation solutions - Import export

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Hugo Beck can claim a decade-long development tradition when it comes to automation. We offer support with our expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines. Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians. Furthermore, various robots systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer‘s needs. Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Forming force NCA 2: max. 1500 N / 5000 N Stroke: max. 60 mm / 120 mm / 240 mm Forming force NCA 3: max. 3500 N / 8900 N Stroke: max. 120 mm / 200 mm Forming force NCA 4: max. 12000 N / 19000 N Stroke: max. 120 mm Forming force NCA 5: max. 31000 N / 47000 N Stroke: max. 100 mm Forming force NCA 7: max. 190000 N / 200000 N Stroke: max. 140 mm

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable from 5 to max. 250 1/min. Press: nominal stamping capacity 400 kN, stroke 20 mm Slide units: max. nominal forming capacity 90 kN, max. stroke 95 mm; NCA units Feed length: servo feed: any feed pitch, mech. feed: max. 500 mm, with feed cycle reduction Material: max. strip thickness: 6 mm, max. strip width 80 mm, max. wire Ø 6 mm Dimensions: width 3,930 mm x depth 1,595 mm x height 2,220 mm Weight: approx. 4,500 kg (without tooling)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: max. 400 1/min. (cylindrical, straight bushes), max. 250 1/min. (flanged bushes, collar bushes) Press: nominal stamping capacity 70 kN, stroke 12 mm Slide units: nominal forming capacity 30 kN, stroke 25 mm Bushing inner diameter: 6 mm - 18 mm Bushing length: max. 40 mm Dimensions: width 2,020 mm x depth 1,330 mm x height 2,030 mm Weight: approx. 3,000 kg

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Thread diameter: M2 - M20 Production speed: max. 260 1/min. Cycle range: 300 - 9000 1/min. Stroke: max. 32 mm

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

VariControl VC 1 - One control platform for all tasks With the VariControl VC 1 machine and process control system, Bihler emphasizes the keywords „Ease of Use“ and „Process Safety“ at a new, higher level. With state of the art software and hardware features, the intelligent control system guarantees greater efficiency in your production. The highly flexible control platform allows you to easily control even the most complex automation solutions in the field of stamping and forming assembly technology – on all Bihler machine types. The integrated „bASSIST“ diagnostic and online help system assists your machine operator just like a second operator at his or her side. Videos, graphics and individually created data simplify adjustment, setup and maintenance operations significantly. The continuous monitoring of all machine and tool functions guarantees maximum machine availability.

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: max. 220 1/min. (cylindrical, straight bushes), max. 160 1/min. (flanged bushes, collar bushes) Press: nominal stamping capacity 100 kN, stroke 12 mm Slide units: nominal forming capacity 50 kN, stroke 50 mm Bushing inner diameter: 15 mm - 40 mm Bushing length: max. 50 mm Material: strip thickness: max. 2 mm, strip width: max. 50 mm Dimensions: width 3,140 mm x depth 1,895 mm x height 2,030 mm Weight: approx. 4,800 kg

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable from 5 to max. 150 1/min. Press: nominal stamping capacity 300 kN, stroke 16 mm (stronger presses on request) Slide units: max. nominal forming capacity 120 kN, max. stroke 95 mm Feed length: mech. feed: max. 500 mm, with feed cycle reduction, servo feed: any feed pitch (as option) Material: max. strip thickness: 10 mm, max. strip width 160 mm, max. wire Ø 10 mm Dimensions: width 3,130 mm x depth 2,100 mm x height 3,100 mm (with protection unit) Weight: approx. 16,000 kg (without units and tooling)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Part size: max. 50 x 50 x 50 mm Part weight: max. 80g / part Bunker volume: 10 – 50 litres (depending on parts) Feeding speed: max. 30 m/min. (depending on part geometries)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable from 5 to max. 700 1/min. Press: nominal stamping capacity 300 kN, stroke 10 mm Slide units: max. nominal forming capacity 50 kN, max. stroke 10 mm Feed length: mech. feed: max. 120 mm or 240 mm, with feed cycle reduction, servo feed: any feed pitch Material: max. strip thickness: 4 mm, max. strip width 80 mm, max. wire Ø 4 mm Dimensions: width 2,950 mm x depth 1,400 mm x height 2,190 mm Weight approx. 7,500 kg

Request for a quote

BVS ELECTRONICS GMBH

Germany

SEW automation solutions With the drive technologies manufactured by SEW, we offer a variety of solutions for a wide range of industries. These are optimally matched to your application and can be used flexibly. Choose from a large variety of frequency converters from the Movidrive, Movitrac, Movidyn and Moviaxis product ranges and benefit from our highquality repairs and other services. The portfolio also includes a number of different motors, servo motors, synchronous motors and geared motors. Since 01.07.2018 we are also an official service partner for SEWEURODRIVE GmbH & Co. KG. With the new, longterm partnership and the even closer and more direct cooperation with the manufacturer resulting from it, you will now be able to make further use of improved services centred around the entire SEWEURODRIVE product portfolio.

Request for a quote

BVS ELECTRONICS GMBH

Germany

SIEMENS CNC and PLC automation solutions Regardless of whether you require CNC control systems for your machine tools, drive assemblies to achieve the highest performance or optimum solutions for your PLC – we should always be your first point of contact. It does not make a difference whether you are using discontinued and legacy series or the latest automation technology products from SIEMENS. With our extensive range of services consisting of general reconditioning and repairs, the exchange and sale of replacement and new parts for a variety of product ranges from SIEMENS, you will receive everything from a single source and always at fixed prices. We will also happily help you with any technical problems if any of your SIEMENS assemblies go on strike. We offer support over the phone as well as a direct on site service so that you can get your machine up and running again as quickly as possible.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Business sectors : environment and renewable energy peripheral equipment for the transport of lightweight consumer goods (≤ 10 kg) by autonomous drones via aerial highways peripheral technological equipment for self-driving land vehicles development and integration of specialist digital solutions for automated production processes

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

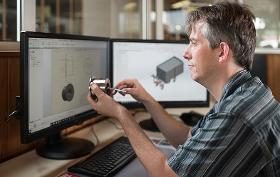

Working in close collaboration with your teams, our highly qualified engineers determine the technical solutions best suited to your specific use. These solutions are analysed, detailed, quantified and drafted. We produce all the mechanical and electrical work drawings and manufacturing documents, develop the automation software, etc. Our technical solutions are developed according to your requirements and technical standards, while prioritising a custom-made product that combines performance and reliability. The feasibility of the selected solutions is systematically reviewed with the manufacturing teams upstream of the production phases. This is one of the advantages to having all of our skilled employees (from the design to commissioning teams) working under one roof

Request for a quote

DOREY

France

Seamvision is a comprehensive inspection system designed to provide another level of measuring seam integrity. It is a continuous analysis for standard and automated solutions that requires non contact imaging and temperature measurements.

Request for a quote

DOREY

France

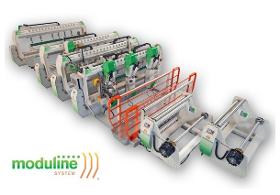

Miller Weldmaster is excited to present our new line of multisealing automated solutions, the Moduline system. Our new Moduline system is designed for the customer looking to increase business profits by automating their production process. Miller Weldmaster designs machines specifically to meet your automation needs while keeping your production and payback concerns in mind. Our years of industry knowledge enables us perfectly pair your application with the properly tailored Miller Weldmaster Automated machine. The Moduline System with its unique design enables you to select multiple automation options regardless of your production demands. FEATURES, FUNCTIONS, & BENEFITS Modular welding gantries for product versatility Modular unwinds with load cells for fabric tension Modular catwalk for simple seam inspections Modular upper and lower welding heads for versatility and accessibility

Request for a quote

DOREY

France

Miller Weldmaster is excited to present our new line of multisealing automated solutions, the Moduline system. Our new Moduline system is designed for the customer looking to increase business profits by automating their production process. Miller Weldmaster designs machines specifically to meet your automation needs while keeping your production and payback concerns in mind. Our years of industry knowledge enables us perfectly pair your application with the properly tailored Miller Weldmaster Automated machine. The Moduline System with its unique design enables you to select multiple automation options regardless of your production demands. FEATURES, FUNCTIONS, & BENEFITS Modular welding gantries for product versatility Modular unwinds with load cells for fabric tension Modular catwalk for simple seam inspections Modular upper and lower welding heads for versatility and accessibility Modular cutting heads for near final productivity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LÖDIGE INDUSTRIES GMBH

Germany

Safe and powerful For an efficient body shell process, the correct bodywork components must be reliably brought from their intermediate storage areas and production lines to be assembled. Lödige’s materials handling and control solutions automate this procedure. Your advantages using Lödige solutions in the body shop: Connection to the pressed component store Conveying on several levels possible Connection to bodywork store Horizontal materials handling systems High levels of automation possible Control connection to robotic systems

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

Innovative manufacturing solutions for the production of light-duty to heavy-duty automotive components. Automotive components and engines considerably vary in size: from small 0.9L 2-cylinder through to 16L V-8 engines. To provide tailored solutions for these components, HELLER consistently focuses on manufacturing systems in modular design. In addition to the “classic” machining centres from the H, F and C series and the RFK/RFN/DRZ machines for crankshaft and camshaft machining, we are offering the following manufacturing solutions: Highlights Wide range of machine technology Model ranges in modular design From stand-alone machine through to fully automated manufacturing system Comprehensive manufacturing solutions Complemented by all services required for the operation of the machinery Advantages For flexible series production For maximum productivity For minimal piece-part costs For a significant reduction of unproductive idle times For highest availability

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

We offer the full range of solutions for process automation tasks implemented with Foundation™ fieldbus and PROFIBUS-PA: The portfolio includes power supplies, power conditioners, multibarriers as well as junction boxes in IP20 and IP67. The range also includes passive connectivity products such as fieldbus cables, field distributors and terminating resistors. The components are suitable for use in harsh environments and can directly be mounted on the machine or in the process.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Our Speedmax is the fastest available wire and tube forming automation solution available on the market for bending machines. By combining NC finger benders with our servo-electric transfer, the Speedmax with its 90 servo axes can reach a speed of up to 4,000 machining steps per minute. The SPEEDMAX is available in three variants (S,M,L). The SPEEDMAX (S) has 20 processing stations and can produce up to 200 parts per minute. The machine concept combines the advantages of 3D-NC wire bending and wire bending by slides. Bending, embossing, notching, flattening, joining, punching, swaging of tubes and wire are possible production technologies in the 20 processing stations. The new SPEEDMAX L has actually 20 processing stations and can produce up to 60 parts per minute. The SPEEDMAX L can work with tube and wire up to a diameter of 12mm and a feed length of 50cm. Various bends in all levels and in the current equipment up to four swaging processes are possible.

Request for a quote

HO-MA GMBH

Germany

A fully automated solution cannot manage without reliable automatic feeding and sorting equipment. In this area we cooperate with well-known manufacturers of vibration and handling elements. The automatic and semi-automatic solutions can also include camera sensors or smart cameras.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Lesjöfors manufactures deep drawn parts to customers individual requirement in press machines by either progressive tool or transfer tool solutions as well as opportunities for less automated solutions in case of low volume requirement.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Due to their compact and flexible design, LS series laser machines guarantee an easy entry into the world of laser processing. We offer manual and automated solutions: - Palletising systems - Bar and coil feed systems - Pick-and-place systems - Robots You can realize the following laser material processing with the LS series: - laser machining for welding, clean welding, cutting, drilling, hardening, and structuring - micro processing - integration of CO2 , Nd: YAG, diode, fibre or disk-type lasers and ultra-short pulsed laser Please get furher information at Download.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Together with our customers, we develop scalable control and automation solutions for their assembly, laser and ECM lines to meet their requirements. In doing so, we attach great importance to the topicality and future-proof development of the technology used. Programming under SIEMENS SPS, SIEMENS NC, BECKHOFF HMI and robot technology are our specialties. We are experts in realization drive and feedback control engineering, electrical project planning, control-cabinet construction, software development and control engineering.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For tubes with diameters from 1/4" to 6". The DB CNC VE series are absolute powerhouses of machines. They can bend tubes in round, oval, square, rectangular, and other special profile shapes. In addition, they are known for outstanding rigidity and power which is unmatched in the market for this size of machines.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

By using an array of sophisticated sound sensors, the SV600 can be mounted close to any equipment or asset, to any area of the production line, or where human access is restricted or dangerous to ensure you can monitor the most important parts of your facility without interruption. As a fixed, automated solution, the SV600 integrates with your process and eliminates the need for lengthy fault-finding processes such as soapy water tests, when used as part of your product leak testing process. By continuously monitoring your environment, you can quickly detect and fix air leaks – reducing your consumption of compressed air and energy to help save your facility money. Key Features: High-end 24/7 acoustic monitoring 64-Digital MEMS microphones placed in a Sunflower Array Integrated visual light camera Powerful processor for onboard real time processing Sound classification Frequency filtering dB values and sound intensity mapping Event triggering

Request for a quoteResults for

Automation solutions - Import exportNumber of results

135 ProductsCountries

Category

- Automation - systems and equipment (14)

- Bending machine tools (10)

- Pumps (9)

- Mechanical engineering - custom work (7)

- Conveyor systems (4)

- Textiles - Machines & Equipment (4)

- Construction - Machines & Equipment (3)

- Electrical systems and equipment (3)

- Laser - cutting and welding machines (3)

- Metallurgy - machinery and installations (3)

- Connectors, electronic (2)

- Foundry machines - centrifugal (2)

- Integrated logistics (2)

- Machine tools - metal machining (2)

- Motor mechanics - hand tools, non power (2)

- Warehouse logistics (2)

- Welding, electric - equipment and supplies (2)

- Acoustic equipment, electric - professional sound-engineering (1)

- Agriculture - Machines & Equipment (1)

- Assembly robots (1)