- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine automation

Results for

Machine automation - Import export

ACEMAL NV

Belgium

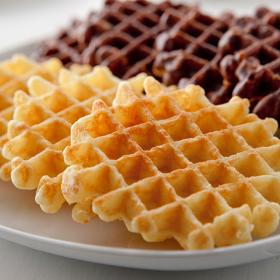

Production machines: Semi-automated or automated production line: Placing of a divider on a TH type oven. On-demand capacity. This type of installation can be automated using a collection robot and a cooling spiral. Automated production line through tunnel oven: From 3500 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

Production machines: Semi-automated or automated production line: Placing of an injector on a TH type oven. From 6000 waffles per hour This type of installation can be automated using a collection robot and a cooling spiral.

Request for a quote

ACEMAL NV

Belgium

Production machines: Semi-automated or automated production line: Placing of a liquid dough injector on a TH type oven. From 2000 waffles per hour This type of installation can be automated using a collection robot and a cooling spiral. Entirely automated production line - TV oven: From 3500 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

Different types: weight, shape The big-sized waffle: about 40 g The small-sized waffle: about 25 g The Soft Waffle exists in rectangular, square, or round shapes. Production machines: Semi-automated or automated production line: Placing of a liquid dough injector on a TH type oven. From 2000 waffles per hour. This type of installation can be automated using a collection robot and a cooling spiral. Entirely automated production line - TV oven: From 3500 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

The filling is made before the baking. Different types: weight, shape The big-sized waffle: about 180 g The small-sized waffle: about 100 g The mini waffle: about 50 g The fruit waffle exists in rectangular & square shapes. Production machines: Semi-automated production line: Manual placing of dough rolls in a TH type oven. Manual or automated waffles collection. From 1300 waffles per hour. Entirely automated production line: From 3500 waffles per hour.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PAULUS STUART SPRL

Belgium

The Tenderstar TSAB tenderizer is a fully automated tenderizing machine that can process pieces of meat measuring 140 mm × 330 mm. This high-end device is ideal for the food processing industries as it can process a large quantity of meat in a minimum amount of time. Quite easy to use, just place the piece of meat on the belt, choose the degree of tenderizing (3 possibilities) according to the hardness of the piece of meat and the 784 needles do the rest. The speed adapts itself and oblique guides keep the meat well centred on the belt. The result obtained is therefore uniform and unmarked for a juicy and tender meat. In terms of hygiene and maintenance, this Tenderstar machine is very practical. Made of stainless steel, it does not rust. In addition, it is quite easy to clean since all parts in contact with the meat can be dismantled without tools to be sterilized or cleaned at very high temperatures.

Request for a quote

RITTAL

Belgium

Depending on the variant, the new, compact Wire Terminal WT fully automated wire assembly machines can produce up to 24 or 36 different wires in cross-sections ranging from 0.5 mm² to 2.5 mm² fully automatically, with zero manual intervention. AS Wire Terminal WT24, The compact Wire Terminal 24 fully automated wire processing machine, ensures efficient,cost-effective wire processing. Up to 24 different, wires in cross-sections ranging from 0.5 mm² to 2.5 mm² may be processed, fully automaticall

Request for a quote

LVD

Belgium

The Phoenix fiber laser cutting machine is an all-around performer. It has the flexibility to expertly cut standard steels and non-ferrous materials in a range of thicknesses and combines high machine dynamics, intuitive machine operation, and advanced automation options to maximize productivity no matter the application. The inherent benefits of fiber laser technology make Phoenix cost effective to maintain and operate. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass Processes different sheet thicknesses without manual intervention Advanced cutting head handles thicker materials “On the fly” cutting in light gauge material Integrated Siemens CNC control and drive system offers high reliability TOUCH-L touch screen graphical user interface control is intuitive and simple to use Automatic shuttle table maximizes uptime PERFORMANCE-ENHANCING OPTIONS CADMAN-L programming software MOVit Automation: TAS, WAS, Compact Tower

Request for a quote

LVD

Belgium

The PPEB-H Series is the choice for heavy bending. These robust, heavy-duty press brakes are custom built for the application. Numerous configurable machine selections and automation options make each PPEB-H press brake a complete, customized solution. LVD’s intelligent bend database optimizes bending parameters for efficient, accurate bending. An intuitive touch screen control reduces the time it takes to go from art to formed part. KEY FEATURES Multiple operating modes ensure optimized ‘Art to Part’ times TOUCH-B touch screen graphical user interface control is intuitive and simple to use Bending parameters automatically controlled by LVD's unique 'intelligent' learning database 2D & 3D color graphics simulate part creation and display material handling sequencing CNC crowning V-axis standard for all models Enhanced Energy Reduction System (ERS) (selected models) Turbo hydraulics (standard) PERFORMANCE-ENHANCING OPTIONS CADMAN-B programming software

Request for a quote

LVD

Belgium

The Extended Tool Magazine (ETM) for Strippit PX punch presses holds up to 40 additional tools and up to 400 tools with the use of indexable multitools. ETM adds tooling capacity, reduces tool changeover time, and increases the efficiency of punching operations. Tools can be loaded and unloaded while the machine is punching. For automated production, the ETM can be combined with a Flexible Automation system (FA-P) or a Compact Tower (CT-P) for loading/unloading, material storage and retrieval. KEY FEATURES Holds up to 40 punch/die combinations, up to 400 tools using indexable multitools Wheel configuration for easy tool access ETM can be loaded and unloaded while the machine is operating Tool life monitoring records the number of hits for each tool Touch-P manages the tooling inventory; identifies the tools required and preloads them into the machine magazine Touch-P touch screen control is intuitive and simple to use PERFORMANCE-ENHANCING OPTIONS

Request for a quote

CLIPPARD EUROPE SA

Belgium

Clippard ES Series Valves The compact ES valve, like Clippard EV and ET valves, converts low voltage, low current signals into high pressure (0 to 105 psig) pneumatic outputs, utilizing a unique, patented valving principle. Since there are no sliding parts, and complete poppet travel is only 0.007”, low power consumption and exceptionally long life are assured with this design. No flow is required for cooling because the compact ES is cool, as well as quiet, in operation. The compact nature of design makes this valve well suited to a wide range of applications in biomedical, environmental test equipment, textile machines, packaging machinery, computerized industrial automation, and portable systems. • Close mounting - 7/8” on center • Overall height less than 1” • Easy to mount on manifold with two #4-40 screws • Geometric design • Polymer housing - Zytel ST 801® super tough • TE Connectivity-style pin connection or 18” wire leads • Flow up to 0.6 scfm (17 l/min) As in the case...

Request for a quoteResults for

Machine automation - Import exportNumber of results

12 ProductsCountries