- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- monitors

Results for

Monitors - Import export

SDT ULTRASOUND SOLUTIONS

Belgium

Valves play a crucial role in the transportation of gas, oil and water throughout your plant. They start and stop flow while also preventing backflow and regulating flow and pressure. They can be found in the hundreds and even thousands at large facilities. Steel, pulp, food and pharmaceutical as well as other industrial facilities installed on their pipes. When valves fail or leak it will result in the loss of energy, product quality and can also lead to potential downtime. Whether it’s internal or external leaks, or issues with flow regulation, valve leaks are a threat to your factory processes. A major component to a plants efficiency is valves operating properly. Ultrasonic inspection can quickly identify function and malfunctioning valves. So they can be tagged and repaired quickly to avoid, diminished production.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Online4US is a multi-channel online monitoring solution that combines both ultrasound and vibration sensors in 4 to 32 channel modular configurations. It answers a necessary demand to have advanced warning of critical asset failure in remote areas. Online4US is designed to provide Reliability teams with continuous feedback about the health of their factory’s most critical assets. It combines data from two of the most relevant asset condition monitoring disciplines (Ut/Vib) to provide advanced insight about potential machine failures. SDT envisioned a need to permanently monitor the condition of critical assets in inaccessible, dangerous, or remote areas. The versatility of Online4US lends its deployment for identifying early stage machine faults before they become catastrophic events. Online4US is designed to remotely identify these defects Bearing condition monitoring Low speed rotating machine defects On-condition acoustic lubrication

Request for a quote

MICROMEGA DYNAMICS S.A.

Belgium

TYPICAL USE Install your monitoring devices anywhere Manage your monitoring device anywhere Access your data from anywhere Alert, report visualization tools FEATURES MONITOR Devices can be located anywhere and connected to the RECOVIB.io platform through a wired Ethernet link or through the mobile wireless network (global coverage). Each MONITOR is factory-configured with a connection key that allows for secured device identification on the recovib.io platform and communication encryption. The MONITOR embedded software automatically takes care of re-transmissions and device re-connections in the event of a poor quality communication link or connection loss to the RECOVIB.IO platform – allowing for a high quality of service even from remote and unattended locations. Monitoring Devices status, connectivity and configuration can be managed remotely making deployment and installation a seamless operation.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Detecting mechanical faults before they stop production Bearing and Machine Maintenance Industry runs on machinery. Bearings, pumps, electric motors, compressors, presses, gearboxes and much more. All of which can break unexpectedly, causing production to stop. When production stops your organization loses money. Few bearings make it to the end of their engineered lifecycle. This is due to poor workmanship, bad lubrication practices and neglect. Problems can even arise right after installation due poor installment of the machine. No two machines are the same. Across industry, machines operate under different loads, climates and conditions, making their maintenance requirements unpredictable. Many machines are still maintained on calendar based PM’s, while others are run-to-failure. Both strategies are wasteful.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

A turn-key condition monitoring solution combining the versatility of ultrasound, the analytics of vibration, standard communication protocols and an embedded trending and analysis software. Vigilant Configure Vigilant to any Critical Asset Vigilant is a flexible data collection pod. Input any combo of eight ultrasound and vibration sensors and receive continuous feedback from your assets. 4 channels for Temperature, Tach and Pressure create an all-in-one solution for critical and guarded assets. Vigilant Highlights: - 8 channels (Ultrasound or Vibration) - 4 channels (Temp/Tach/Process) - Embedded data management software - Trends/Spectrum/Waveform/Waterfall - Open communications protocol - Static and Dynamic data

Request for a quote

GEMONE

Belgium

Verify if machines are utilized beyond contractual agreements. Invoice for additional usage or modify the contract to accommodate your customer's evolving requirements.

Request for a quote

GEMONE

Belgium

Save both time and money by staying informed about the whereabouts of your machines not only during daily operations but also in case of incidents. GemOne provides real-time tracking of your fleet and securely stores the data, enabling you to utilize it for reporting or making business decisions. Rest assured, it fully complies with GDPR guidelines.

Request for a quote

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

TAOBÉ CONSULTING

Belgium

The very first step of every cosmetics registration in Europe starts with the full assessment of the formula of the product to confirm it meets the EU requirements. During this step, our Safety Assessors will: - Check all documents related to the ingredient (MSDS/COA/Non-animal testing/IFRA, etc.). - Verify that the ingredients do not have restrictions established by European regulations and that the limits of use (if there are any) are in compliance. - Check that the ingredients used are suitable for cosmetics (cosmetic grade ingredients). - Check the toxicological profile of each ingredient. - Verify if the ingredient contains any impurity. - Check the SCCS opinions, industry guidelines and other regulations (REACH, CLP). - Calculate the MoS (Margin of Safety) for each ingredient and/or search for supporting documents (reliable literature) that declare each ingredient safe at the added dose in the finished product.

Request for a quote

TAOBÉ CONSULTING

Belgium

All cosmetic products must display the following mandatory information on both the container (inner label) and packaging (outer label): - Name and address of the Responsible Person - Nominal content - Date of minimum duration or PAO - Country of origin (if the product is imported into the community) - Product function (unless it’s clear from its presentation) However, there are exceptions for the following three items, which we will discuss in detail later in this article. - Warnings - Batch number - INCI list Please keep in mind that the items mentioned above are specified in EU Regulation 1223/2009, which outlines the requirements for cosmetics. However, it’s important to understand that various laws govern product labelling, such as the Packaging & Waste regulations, which can vary from country to country. We encourage you to explore our article on Labelling and Packaging Regulations for more information, including details about recycling symbols.

Request for a quote

TAOBÉ CONSULTING

Belgium

The CPSR consists of two parts, A and B: in Annex I of the Cosmetics Regulation, all the information that must be collected and processed by the Safety Evaluator in order to identify and quantify the dangers that the cosmetic product may present for the human health, namely: PART A contains information on the safety of the cosmetic product, such as: 1. Quantitative and qualitative composition of cosmetic products; 2. Physical/chemical characteristics and stability of the cosmetic product; 3. Microbiological quality; 4. Impurities, traces, information on packaging material; 5. Normal and reasonably foreseeable use; 6. Exposure to the cosmetic product; 7. Exposure to substances and calculation of the MoS; 8. Toxicological profile of substances; 9. Undesirable effects and serious undesirable effects; 10. Information about the cosmetic product. PART B holds the conclusion, the warnings and instructions of use to label, the scientific reasoning and the assessor's diploma.

Request for a quote

TAOBÉ CONSULTING

Belgium

A thorough toxicological evaluation on raw materials is key if your company has ambition to sell raw materials to European manufacturers, as the raw materials must meet certain requirements to guarantee their safe use in cosmetic products. By making this evaluation available, you increase the sales possibilities all over Europe. This is also a key step to be able to approach the big players (L’Oréal, Estée Lauder, etc.) who will consider you as a serious partners as you will show a non-negotiable approach to quality and ensure the highest level of effectiveness and safety to end-customers. Taobé’s safety assessors will be able to develop a Dossier including: -A full toxicological assessment report of the raw material, according to the SCCS Notes of Guidance, demonstrating the safety of the cosmetic ingredient/s according to the utmost authority in Europe. -A CLP SDS, to provide to importers for REACH notification.

Request for a quote

MICROMEGA DYNAMICS S.A.

Belgium

Our innovative measurement system allows for vibration measurements to be taken of whole-body vibration exposure according to ISO 2631. Its autonomous sensors that do not need to be wired during measurements and automated artefact detection provide for a user-friendly implementation and use (can be used by non-experts). Stored data is downloaded from the sensor(s) at the end of the working period to a smartphone or a PC using a Bluetooth connection. The software allows for the automatic computation and display of workers’ exposure to whole-body vibrations and indicates how such exposure compares with the limit and action values defined in the vibration Directive. The set of whole-body vibration meters (Vib@Work Seat, Vib@Work Floor & Vib@Work Detect) can measure the vibration exposure of either seated or standing operators. In addition, when used in conjunction, seat efficiency can also be measured (i.e. S.E.A.T. factors).

Request for a quote

MICROMEGA DYNAMICS S.A.

Belgium

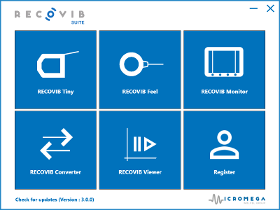

various RECOVIB® devices (Tiny, Feel & Monitor), to visualize recorded data and to convert them to various data formats (txt, wav, MATLAB, LabVIEW, HDF5 etc.). The free Recovib.Suite is composed of 5 application modules The Recovib.Tiny Module allows the user to set up the Recovib.Tiny vibration recorder (i.e. to define the recording period) and to download the recorded data to the host PC. The Recovib.Feel Module allows the user to visualize and record signals acquired with the Recovib.Feel USB vibration sensor connected to the host PC. The Recovib.Monitor Module allows the user to visualize and record signals acquired with Recovib.Monitor acquisition systems connected to the host PC. The Recovib.Converter Module allows the user to export the data recorded by the Recovib devices in various data formats (txt, wav, MATLAB, LabVIEW, HDF5 etc.). The Recovib.Viewer Module allows the user to replay the data recorded by the Recovib devices.

Request for a quote

MICROMEGA DYNAMICS S.A.

Belgium

The RECOVIB.SHIVER are outdoor stations dedicated to the monitoring of site emission levels and able to report vibration, particle density and air pressure. The SHIVER devices are linked to the recovib.io platform (Micromega Dynamics Cloud Software) in order to offer a near real-time reporting solution with norm comparison. The use of SHIVER devices ensures environmental and workplace compliance and helps to maintain good relationships with neighboring people and businesses. Monitoring of buildings close to quarries following blasting activities generating vibration and/or air overpressure Monitoring of buildings, sensitive equipment and the comfort of residents following surrounding construction work Monitoring of buildings, sensitive equipment and the comfort of residents exposed to road and railway traffic noise Vibration velocity, particle density and air overpressure measurements

Request for a quote

MICROMEGA DYNAMICS S.A.

Belgium

The Recovib.Monitor devices are industrial grade multi-purpose acquisition and monitoring systems. They provide a full embedded solution for connecting up to eight sensors (current loop, IEPE, single-ended/differential voltage) to a hardware platform that can acquire process, store and display data in several ways. They can either stream sensor’s raw data to a local machine or send secured messages to the Recovib.io platform. In that mode, they can be remotely configured and customized to fit customer’s needs. Based on our extensive background in wind turbine structural parts monitoring, the MONITOR devices provide flexibility, precision measurement and dependability – even in harsh, remote environments.TYPICAL USE Local or remote vibration measurement; particularly structural monitoring FEATURES Local use with the Recovib.Suite software Synchronized input channels Time management (connection to an NTP server) Very High dynamics (>120 dB)

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Powerful • Analytical • Versatile The Ultranalysis® Suite 3 is a versatile application to manage, trend, and analyze ultrasound and vibration data. Organize your condition monitoring strategy with Ultranalysis® Suite 3. Ultranalysis provides powerful flexibility to manage any combination of assets; from a few hundred to several thousand. An asset database is your condition monitoring roadmap. UAS3 is compatible with SDT270, SDT340 and LUBExpert providing the flexibility to manage any combination of assets and tasks. You can manage data in your own language, UAS3 features seven languages including English, French, Dutch, German, Italian, Spanish, and Russian. Organizing your condition monitoring program has never been easier with UAS3. Hierarchical tree structure with seven levels Tree structures grouped in data folders Unlimited tree structures and data folders Expand/Collapse of any level node UAS3 includes Bearing Toolbox that will help diagnose bearing faults.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SDT ULTRASOUND SOLUTIONS

Belgium

Find Air Leaks. Decrease Energy Consumption. Maximize Uptime. Compressed air is the most versatile and therefore widely used resource in industry. Using atmospheric pressure to transfer energy during industrial processes, compressed air can be found powering air tools like drills and hammers, hydraulic air cylinders for automation in manufacturing processes and much more. Compressed air is also used to power air brakes on mobile fleets and trains. Air Compressor Expenses It is so commonly found in industry it is often referred to as the fourth utility to electricity, water and gas. Of the four, compressed air consumes the most energy. Air compressor systems can differ very greatly in size, output and cost. What remains constant, is the initial investment in a compressor system is only 25% of the expenses associated with it, over its lifetime. The other 75% of the costs go to energy used to compress the air.

Request for a quote

ALX SYSTEM

Belgium

POWER LINE MONITORING Let’s automate repetitive tasks Home POWER LINE MONITORING POWER LINE MONITORING Let’s automate repetitive tasks Context Power lines need to be monitored to find default in their structure. Current situation Analysis is usually made through a helicopter which is costly or by manual inspections which is dangerous. Our solution ALX System provide automatic path following, with detection of default in power lines. We provide planes able to fly for about 10.000 Km without interruptions

Request for a quote

ALX SYSTEM

Belgium

PIPELINE MONITORING Protect and analyze pipelines Home PIPELINE MONITORING PIPELINE MONITORING Protect and analyze pipelines Context Pipelines are often targets of terrorists. In addition of criminals acts, leaks due to structure age or default can leads to explosions. Current situation Today, workers are verifying manually the pipes and takes risks for their lives. Sometimes manned planes are used to do the verification. Our proposal We propose automatic surveillance of pipelines, to detect leaks and threats automatically. We provide planes able to fly for about 10.000 Km without interruptions.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Keep Your Steam Clean, Safe And Energy-Efficient Steam is an essential resource is many industrial processes. As a result most facilities have a vast network of piping, valves, flanges and steam traps. Within these systems there exists constant flow and turbulence. As pure steam travels from your boilers to their point of use, some cooling is inevitable. The result is accumulated condensate and gases. Steam traps purge this waste and keep your system pure. A fully-functional steam trap opens, closes or modulates automatically. It discharges condensate once formed, unless the heat from the condensate can be used. It is energy-efficient and does not waste quality steam. It removes impurities from the live steam, and maintains purity and efficiency throughout the system. Steam Trap Failure Causes Losses to Product Quality, Safety and Energy Loss Steam traps are necessary for the overall efficiency of heat energy transfer.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

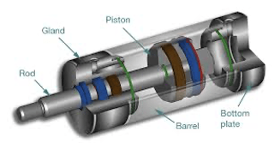

Non-rotating asset components seldom receive the routine surveillance they need Hydraulic systems represent another way industry converts electricity to mechanical energy. A pump, normally powered by an electric motor, moves hydraulic fluid through a system. The system is typically made up of a reservoir to hold the hydraulic fluid, high pressure lines to carry the fluid, control valves that ensure the fluid is sent where needed, relief valves for safety, and cylinders to produce mechanical energy. The pump and motor receive attention while the balance of the system is run-to-failure. Ultrasound testing could change this lackadaisical approach; especially considering its versatility, ease of use, and applicability to most hydraulic defects. External and Internal Leaks External leaks can often be found by visual inspection. Some external leaks, like a ruptured hose or fitting, are easy to spot. Simply follow the trail of spilled oil. Others are not so obvious.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

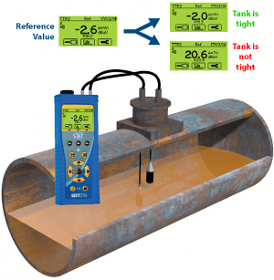

Peace of mind and reassurance for the operator Tightness Testing on Underground Storage Tanks and other Air Tight Compartments The ability to test for tightness with an ultrasound detector is extremely powerful and versatile. It is the only way to ensure that underground storage tanks are air tight. But that isn’t all that ultrasonic tightness testing can be used on. There are many things that need to be air tight. Like the engine or cabin of a car, large shipping containers or the bearing housing in a paper production plant. When somethings tightness integrity deteriorates one or two things can happen. Things can leak out, or things can get in. And whenever possible, it is advantageous to avoid either of these from happening. Fuel Leaking From Underground Storage Tanks Damage the Environment and Waste Valuable Resources Overtime the tightness integrity of underground storage tanks or other air tight compartments can deteriorate.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Safely Inspect Electrical Systems with Ultrasound Electrical failures pose a tremendous safety threat and have the ability to shut down operations entirely Industrial plants require a lot of power to operate, and much like the machinery required for production, their electrical systems can also fail. The Importance of Maintaining your Electrical Systems The implications of a total electrical system failure are far more severe than that of an ordinary mechanical failure. They have the potential to damage equipment, cut power flow and cause downtime for days, seriously injure or kill workers in the immediate vicinity and even impact the surrounding areas power grid. Faults in electrical systems can be detected at their earliest stages with regular ultrasound inspection and therefor prevented far before anything catastrophic happens.

Request for a quote

TRU

Belgium

Our employees receive on-site guidance to ensure a flawless start. We monitor their work effort continuously and check the quality of their work and their documentation. We also have a trained back-up available for each employee, which enables us to meet all cleaning agreements and deadlines.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

SDT was the first to pioneer on ultrasound-based hatch cover weathertightness testing on board of ships back in the late 1980s. Together with MacGregor, Lloyds Register of Shipping and IMCS, SDT was able to put ultrasound testing of hatch covers on the world map and make it the preferred method for testing hatch covers by charterers, shippers, P&I insurers and stakeholders in the marine industry. Another first position for SDT is that further development of the tightness testing equipment resulted in SDT launching the world’s first Class type approved and bespoke SHERLOG product range in 2000. Ever since, the SDT SHERLOG equipment became a symbol of reliable and professional hatch cover testing. As no solution is complete without training, SDT & IMCS developed the first and only training course for ultrasound testing of hatch covers in line with the IACS UR Z17 criteria.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

CONMONSense delivers precise, repeatable data about the health of your assets and electrical systems also in the most challenging environment. Its resonant piezo element is optimized for ultrasound driven lubrication, mechanical fault detection, and monitoring the health of valves, steam, hydraulic systems and electrical defects. Ultrasound is a true measure of the FITness of your facility. Most assets produce FRICTION, IMPACTING, and TURBULENCE as defect indicators. CONMONSense hears these phenomena at their inception and delivers an analog signal response to your connected measurement system. With an output range from 4-20mA or from 0-10V, CONMONSense mounts permanently to any asset to provide continuous condition monitoring data. Avoid unplanned downtime and put the safety of your plant and colleagues first.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Detect, Trend, and Analyze Ultrasound and Vibration. Detect, trend, and analyze asset health by viewing the ultrasound and vibration time signal and spectrum directly on the SDT340. A reliable asset delivers its engineered value when it is most needed. And while the responsibility for reliability belongs to everyone, it is the maintenance team who is called upon first, when things go wrong. For this reason, the SDT340 connects maintenance to reliability in ways we never imagined possible. Manage the results and organize your condition monitoring strategy by uploading them to the Ultranalysis® Suite 3 software (UAS3). Control any combination of assets and tasks thanks to its flexibility. SDT340 keeps inspectors connected to their assets. Live timewave and spectral views allow inspectors to perform in-the-field diagnosis and analysis, a job previously performed in the office.

Request for a quoteResults for

Monitors - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Monitoring and control equipment (17)

- Scientific and technical monitoring (8)

- Sensors (2)

- Measurement - Equipment & Instruments (2)

- Batteries (2)

- Monitors, computer (1)

- IT networks - management and backup (1)

- Audio and video accessories (1)

- Business intelligence (1)

- Clean room systems and processes (1)