- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pharmaceutical

Results for

Pharmaceutical - Import export

LAMBIOTTE & CIE

Belgium

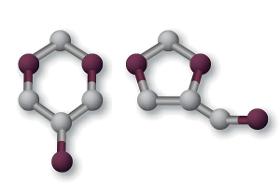

Molecular formula2 (C4H8O3) Molecular weight104.1 CAS number4740-78-7 and 5464-28-8 EC number911-694-8 IUPAC name1,3-dioxan-5-ol and 1,3-dioxolan-4-ylmethanol EC nameReaction mass of 1,3-dioxan-5-ol and 1,3-dioxolan-4ylmethanol

Request for a quote

LAMBIOTTE & CIE

Belgium

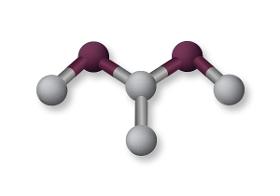

Molecular formulaC4H10O2 Molecular weight90.1 CAS number534-15-6 EC number208-589-8 IUPAC name1,1-dimethoxyethane EC name1,1-dimethoxyethane

Request for a quote

TRU

Belgium

Besides continuity, TRU Cleanroom Cleaning offers you extensive expertise in clean-room and equipment cleaning. We train technical operators in accordance with the strict requirements of the pharmaceutical and biotechnical sectors and adopt the ‘Training Within Industry’ approach. Thanks to CEO Vanessa Morini’s years of experience , we are able to meet the most demanding equipment cleaning needs of the sector, both at a technical and chemical level. We ensure an efficient communication structure and we employ a proactive, strategic approach. Together, we strive to achieve the best possible result.

Request for a quote

TRU

Belgium

Vertalingen toevoegen equipment cleaning Sectors like the pharmaceutical and biotech industries are constantly growing. As a result, there is a huge demand for technical and scientific talent. At the same time, workloads continue to rise because of increasing complexity, production processes are changing ever more rapidly, and it has become harder and harder to find the right profiles. All this while operators are spending roughly 30% of their time carrying out repetitive tasks such as equipment cleaning. Why not outsource this job to a professional so your operators can focus on their core activities? This will allow you to boost your production capacity by up to 30%!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KURARAY (EVAL EUROPE N.V.)

Belgium

As product formulas become more complex, they often become more volatile andsensitive to oxygen. EVALâ„¢ provides a functional barrier in both directions: assuring formula integrity and quality while blocking the permeation of external gases and contaminants. Unbreakable all-plastic barrier structures with EVALâ„¢ allow transparencyand squeezability for safe and convenient use. In addition to flexible pouches and SUP, typical applications inlcude ampoules, bottles, eye liquid dosers and inhalers.

KURARAY (EVAL EUROPE N.V.)

Belgium

EVAL offers a reliable alternative to aluminium foil, with excellent stress crack and pinhole resistance. Multilayer barrier films with EVALâ„¢ can be laminated onto a varietyof different substrates to provide sachets with functional barrier. Sealable and anti-scalping Specific grades of EVALâ„¢ film can be laminated to a substrate, providing the sachet or pouch with both barrier properties and a sealable internal contact layer with excellent anti-scalping properties.

KURARAY (EVAL EUROPE N.V.)

Belgium

In addition to oxygen and CO 2 gas barrier, EVAL™ provides an outstanding odour barrier, especially useful for ostomy applications. EVAL™’s functional barrier works in both directions, protecting contents against contamination while keeping them from escaping into the environment. Flexible barrier structures provide an efficient disposable solution for biomanufacturing. When incinerated, the tiny but functional amounts of EVAL™ in the structure release only CO 2 and water vapour.  No dioxin, no metal residue.

KURARAY (EVAL EUROPE N.V.)

Belgium

EVAL's largest use world-wide is for food packaging. Since 1972, EVALâ„¢ has helped reduce food waste by blocking oxygen ingress and contaminants, extending shelf life and avoiding product waste. EVAL provides the functional gas and contamination barrier to the entire structure. The result has often been a reduction in packaging waste by reducing the weight and amount of packaging materials used, without compromising on function. Â EVAL barrier properties avoid vitamin and fat oxidation, extending shelf life of parenteral nutrition. Compared to standard plastic packaging, additive content can be guaranteed for longer, even while reducing the necessary doses. EVAL barrier can be added to many different types of light weight, unbreakable and halogen-free all-plastic packaging, improving safety in use and reducing environmental impact.

KURARAY (EVAL EUROPE N.V.)

Belgium

EVAL is already used world-wide to improve the safety, shelf life and process efficiency of packaging for baby food and other infant formulas. With a reliable performance, shelf-stable packaging can be designed to safely limit the total amount of oxygen ingress. Quality is assured and shelf life is extended, notably by protecting fat and vitamin content against oxidation. Additional safety and extended shelf life with oxygen scavenger For the most oxygen-sensitive products, EVALâ„¢ grades with oxygen scavenging capacity can create a negative oxygen increase, providing extra safety margins and extending product shelf life.

KURARAY (EVAL EUROPE N.V.)

Belgium

Kuraray offers EVAL resins for the medical and pharmaceutical industry for the production of either transparent or opaque films suitable for use in form-fill-seal equipment or for preformed packages. Highest oxygen barrier thermoplastic resin available Excellent thermoformability Halogen-free chemistry - can be easily extruded and safely incinerated Recyclable with existing infrastructure FDA and USP Class VI compliant Adding layers of other specialised materials can result in sophisticated, high-performance structures. While 5-layer coextruded barrier structures are commonly produced, structures of 7 or more layers are often more effective concerning both performance and cost. In the structures below, EVAL provides the oxygen and contamination barrier, and cyclic olefin copolymers (COCs) provides water vapor barrier.  The result is an extremely performant blister pack that is free of both halogen and chlorine. Â

KURARAY (EVAL EUROPE N.V.)

Belgium

As pharmaceutical architecture becomes increasingly complex, so does its sensitivity to oxygen and contamination. EVALâ„¢provides superior oxygen and chemical barriers that offer safe and transparent alternatives to PAN, PVDC and aluminium foil. Â Add EVALâ„¢ barrier to a wide range of packaging options from pouches, SUP and overwrap to bottles to formed push-through packs. For the most sensitive applications, unique oxygen scavenging EVALâ„¢, adds extra safety and extends shelf life by reducing oxygen ingress to zero.

Results for

Pharmaceutical - Import exportNumber of results

13 ProductsCountries

Company type