- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bending of sheet metal

Results for

Bending of sheet metal - Import export

TRIBUNAS & FIGUEIREDO, LDA

Portugal

We offer sheet metal bending services up to 3m. We have high-performance press brakes with 7 axes and up to 160 tons of bending force.

Request for a quote

NOVELTY STEEL

Turkey

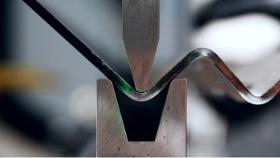

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

ESTIMET SP Z O.O.

Poland

We provide sheet metal bending services using three precision Trumpf press brakes (TruBend_3100, TruBend_5085; TruBend_5320) with a maximum pressure of 320 tons and a maximum bending length of 4000 mm. Our well-equipped inventory of bending tools enables us to manufacture even the most complex parts, and dedicated software supporting machine operation allows us to simulate the bending process. All this guarantees the execution of orders with extreme precision and accuracy. In addition, in our machine park we have two CNC bending machines for bending pipes and profiles. We operate on both mandrel and mandrelless benders, while specializing in bending pipes and profiles. In our plant we deal with bending of, among other things: - structural steel - galvanized steel - stainless steel - aluminum

Request for a quote

ELEKTRON SP. Z O.O.

Poland

“Bending” is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in plastic materials, most commonly sheet metal. Commonly used equipment includes box and cup brakes, press brakes, and other specialised machine presses. Typical products that are produced in this way are boxes, such as electrical enclosures and rectangular ducts. Bending sheet steel The combination of modern presses, advanced matrix, stamps and the experience of our employees provides excellent results in the form of professionally performed artistic processing of various sheets. We bend sheets quickly and extremely precisely, and thanks to the fact that the process is fully repeatable and automatic, we can undertake even very large orders. The maximum pressure of our machines is as much as 200 tons, thanks to which we can undertake artistic processing of materials with a thickness of 6 mm over a length of 3 meters.

Request for a quote

BOHEMIA METAL PARTS

Czech Rep.

We'll bend and set the sheet meta according to your drawing, so that the metal products get firmness, which helps you to save money on welding

Request for a quote

MARXAM PROJECT

Poland

CNC bending of sheet metal technology is the most popular method of plastic processing, allowing to obtain details of both simple and complex shapes. The use of modern press brakes allows for the maximum possible repeatability in cnc bending of the produced elements for any number of items. The modern CNC tube bending services and the automatic compensation of the deflection arrow give maximum accuracy and repeatability in 7 axes and allow you to maintain the required angles along the entire length of the bending line. An extensive tool park allows us to adapt to any customer’s technological requirements. We offer sheet metal bending services, such as tube bending, metal curving, metal sheet folding, aluminum sheet bending, bending steel and many more.

Request for a quote

TARET

Poland

We bend metal sheets on numerically controlled (CNC) bending machines from AMADA, LVD, PROMECAN, DURMA. In addition to bending sheets in a straight line, we also perform profiling on cylinders and bending pipes and profiles. We have 9 CNC press brakes, on which we can bend elements up to a length of 4 meters. Our largest press has 4 meters of working length and 320 tons of pressure. In the near future, our machine park will be enriched with a robotic station for bending sheets with an Amada press with a length of 4 meters and a pressure of 220 tons.

Request for a quote

HIRSCH KOVIFLEX D.O.O.

Slovenia

* Bending up to 4000mm in length * 240 tons of power We bend even more complex products and, if necessary, manufacture unique tools. Bending all types of materials and thicknesses. CAD models are used for bending simulation.

Request for a quote

MR CO. LTD.

Ukraine

Sheet metal bending is one of the vital processes of metalworking. The sheet bending workshop of MR Ltd is equipped with the latest European equipment, which provides unsurpassed results. Thanks to CNC technology, the entire folding process, from programming and the tool setting to bending, is very productive. Our equipment and experience allow us to perform work of any complexity, from single orders to large-scale production.

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC bending up to 3000 mm 100T, - Rod bending up to 16 mm, - Tube bending up to 30 mm; - Sheet bending.

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC bending up to 3000 mm 100T; - bending of threaded rods up to D12.

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC bending up to 3000 mm 100T; - bending of threaded rods up to D12.

Request for a quote

METALUX

North Macedonia

At our company, we take pride in offering CNC bending services that adhere to the highest standards of quality and precision, utilizing Press Brake's advanced bending technologies. We provide a wide range of CNC bending operations, tailored to meet each customer's specific preferences and needs. Quality is of paramount importance to us, and we are committed to maintaining this principle throughout all our CNC bending operations. To achieve exceptional results that meet our stringent quality standards, we rely on the industry's best-performing machines – Press Brake bending technologies. As your trusted OEM partner, we meet production demands with an agile approach and strict quality control, ensuring precision in every piece. Contact us now to discuss your needs and partner in shaping a brighter future for your sheet metal endeavors.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The material is aluminum. The process is CNC laser cutting and bending.

Request for a quote

ELEKTRON SP. Z O.O.

Poland

We provide sheet metal bending services. Our sheet bending is carried out with the help of edge presses with very high accuracy, long-series elements can be implemented through an automated device that supports the work of qualified operators. Material possibilities: • we have three press brakes that enable sheet bending at a length of 3000 mm. • The maximum bending length is 3000 mm • The maximum thickness of bending over a length of 1000mm – 5mm and 8mm • Pressure – 125 and 135 tons • With Laser head for cutting material at an angle – 3D Please send your inquiry to the following e-mail address: biuro@web-elektron.pl

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SC PROFINOX SRL

Romania

We provide CNC bending services, performed according to the highest standards of quality and precision, using Abkant’s highperformance bending technologies. We carry out various CNC bending operations, depending on the customer’s wishes and needs metal bending, CNC pipe bending, bending of elements obtained through other technological operations. We value the quality of the products and services we offer and ensure that CNC bending operations do not deviate from this principle. For the results we achieve to meet the expected quality standards, we rely on the bestperforming machines in the industry – Abkant bending technologies. Abkant bending machines are ideal for bending metal sheets, CNC pipe bending, but also for bending cut parts, proving highly efficient even in the most difficult radii. Abkant CNC equipment is renowned for the “intheair bending” technique it uses, allowing very precise bends.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC milling and bending. The material is aluminum. The surface treatment is purple anodized.

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

GSW SCHWABE AG

Germany

A perfect combination of space savings and dynamics: the GSW Compact Feed Lines Our Compact Feed Lines are an ideal answer to the challenge of a constraint floor and necessity to process thick materials. Marrying the processes of leveling and indexing into one Feeder-Straightener machine allows for a complete Feed Line with only two individual machines and thus greatly reduces the necessary length. Additionally, the decoupling of the coil mass from the indexing process – achieved through a short loop between Coil Reel and Feeder-Straightener – enables dynamic feeding despite the compact footprint. And, if cross-sections are especially big, the loop can be spared completely, creating yet more space. One more advantage, virtually a by-product out of their very nature, is the quicker set-up of our Compact Feed Lines. This elevates them to not only space- but also time-savers!

Request for a quote

GSW SCHWABE AG

Germany

With Conventional Feed Lines, the focus lies on speed and material surface. That’s why Conventional Feed Lines are equipped with a Coil Reel for pull-off, a Straightener with variable frequency drive a coil loop and a Servo Roll Feed: the loop uncouples the more inert straightening process from the highly dynamic indexing process and thus allows for high line speeds and preservation of the material surface. Since productivity and capacity demands can vary significantly, we have created different control concepts: while small Feed Lines work with a simple pneumatic drag brake at the Coil Reel and an ultrasonic sensor to control the Straightener speed, the large Feed Lines get fully synchronized controls with motor-limited Coil Reels and a smart loop, creating a steady average speed of the whole line. This allows smooth pull-off of high coil weights while the loop remains very calm – in addition, the Servo Roll Feed can work with full dynamics, even at long indexing progressions.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is laser cutting and bending. The material is stainless steel. The finish is cleaning and deburring.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Laser cutting welding stainless steel 304 sheet metal cover for machinery parts

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Laser cutting welding stainless steel 304 sheet metal cover for machinery parts

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Laser cutting bending aluminum sheet metal parts

Request for a quoteResults for

Bending of sheet metal - Import exportNumber of results

134 ProductsCountries

- China (32)

- Turkey (22)

- Poland (12)

- Taiwan R.O.C. (12)

- Germany (10)

- Slovakia (8)

- Lithuania (5)

- Bulgaria (3)

- North Macedonia (3)

- Portugal (3)

- Serbia (3)

- Slovenia (3)

- Ukraine (3)

- United Kingdom (3)

- Czech Rep. (2)

- Italy (2)

- Switzerland (2)

- Belarus (1)

- France (1)

- Hungary (1)

- Netherlands (1)

- Romania (1)

- Russia (1)

Company type

Category

- Bending - steels and metals (46)

- Sheet metals - stamping (29)

- Milling - steels and metals (14)

- Industrial sheet metal work (9)

- Finished Metal Products (7)

- Metal straightening machines (4)

- Bending machine tools (3)

- Laser - cutting and welding machines (3)

- Coil winders (2)

- Cutting - steels and metals (2)

- Folding machine tools (2)

- Forming - steels and metals (2)

- Sheet Metal & Tubes (2)

- Turning - steels and metals (2)

- Welding work - steels and metal (2)

- Aluminium alloys (1)

- Compactors and crushers (1)

- Construction, industrial - contractors (1)

- Doors, house (1)

- Electrical & Electronic Components (1)