- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cardboard - manufacturing machinery

Results for

Cardboard - manufacturing machinery - Import export

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

Quality control and testing is the most important step in the production cycle. Aiming to meet the set requirements for production. Ensure product quality and sustainability by implementing good quality control methods. As machines are busy manufacturing, there are multiple parameters that can influence the product quality. Certain factors include humidity, adhesives, board styles or flute types. Based on these parameters, product recipes must be adapted to meet the requirements. To measure cardboard strength, large EOL testing machines are used for quality control. By using a portable, easy to use cardboard tester for bend strength, cardboard can be adequately tested at any location.

Request for a quote

LEON ENGELBRECHT DESIGN CC

Namibia

Say hi to the latest addition of our curated selection of Homeware products. The L E D solid wood cheese / snack / chopping boards. Made from solid Prosopis wood which is a sustainable wood source in Namibia. Add a bit of style and proudly “Namibian made” flair to your next dinner party or sundowner experience.

Request for a quote

YMCUP

Turkey

YM/BKM-DK Series printing and punching machines can print on single - and double - sided PE coated paper. Suitable for use with water-based ink for printing. The ink reservoir is made of stainless steel and is environmentally friendly. Printing and punching machines allows quick drying with fan and infrared dryers. Usage of servo motor gives more efficient printing

Request for a quote

YMCUP

Turkey

YM/KSM-DK Series machines are big size machines due to product size. Their operating performances are slower compared to other paper products. Salad bowls, which are a part of the rapidly developing fast food sector, have become one of the preferred ones in the sector with ease of use, transport and consumption.

Request for a quote

YMCUP

Turkey

YM/KKM Series which can produce 60 pieces per minute is suitable for the use of double- sided PE paper and heps you to manufacture quality production with ultrasonic side bonding method. In recent years, being eco-friendly and having the disposable features of paper bowls’. which have gained a place in the sector, helped to expand the product range rapidly. YM/KKM-DK series machines are designed to take you to the highest level in this sector. This model of ours produces soup , dessert & round box . As an option,hot air and resistance sticking method is also available in this model

Request for a quote

YMCUP

Turkey

YM/DW-DK series; It is suitable for the use of double and single sided PE paper, and helps you to make quality production with glue and ultrasonic side bonding method. The most important speciality that distinguishes double wall cups from other paper cups is that they are produced with double-layer paper . Thus, in hot drinks, the consumer can hold the paper cup with hand without discomfort and the beverage in the paper cup does not get cold in a short time.

Request for a quote

YMCUP

Turkey

YM/KBM-DK80 Series paper cup forming machines are automatic environmetal machine with multiple program structure. The materials used, such as paper, silicone oil, are completely healthy and environmentally friendly. Our machines are suitable for the use of SINGLE-AND DOUBLESIDED PE COATED paper. It is the ideal equipment for the production of cups used in every area of your life, providing ease of use with hot and cold beverages.

Request for a quote

YMCUP

Turkey

YM / KBM - DK110 series, which can produce 110 pieces per minute; It is suitable for the use of double-sided PE paper and helps you to produce quality with ultrasonic side bonding method.It is fast, ergonomic, takes up less space than its peers and saves a lot of electricity compared to its competitors.There is no need for an extra compressor in our YM / KBM-110 series machine that you would like to see in your business.Ymcup has placed the compressor in the machine compactly for you.Thanks to this model , we guarantee to increase your production capacity substantially .

Request for a quote

YMCUP

Turkey

YYM/PRO Series cutting machine is a machine that works with a servo control system. Our machine is suitable for cutting single and double sided PE paper. The cutting machine, which can reach up to 450 strokes per minute, can easily cut your pre-printed bobbin paper. With its automatic edge control system, it provides smoother cutting and ease of use to the operator. It can print and cut thanks to the optional single color printing on it. You can easily place your bobbin paper with the hydraulic bobbin lift unit. YM CUP family provides you with all the support from the installation of all the machines it has produced, and enables you to make a trouble-free production with minimum manpower.

Request for a quote

TOPPY PACKAGING

Italy

Master Toppy is our top performing pile turner for turning, vibrating and aligning stacks up to 3000Kg. Ideal when used in-line with die-cutting and laminating machines.

Request for a quote

PAK-PROJEKT

Serbia

The machine is used for the production of cardboard boxes. Working width is from 1400 to 2400 mm. Machines have a tool for punching handle, cross-cut, automatic feeding and storage of finished boxes. Capacity of 300 to 800 boxes per hour. We have the option of machines with servo drive. pakprojekt@gmail.com, info@pak-projekt.rs, www.pakprojekt.com

Request for a quote

YMCUP

Turkey

YM/PKT-DK Series machines provide you minimum manpower - minimum labor, provides ease of use with aesthetic desing, clear PLC control panel. You can package all the dimensions in one machine and you can maximize your product quality in the paper cup sector where the product range is very wide. While 1 personnel controls 2 machines in manual paper cup collection, 2 personnel is sufficient for 20 machines in automatic packaging machines.

Request for a quote

YMCUP

Turkey

YM/PKT-DK Series machines provide you minimum manpower - minimum labor, provides ease of use with aesthetic desing, clear PLC control panel. You can package all the dimensions in one machine and you can maximize your product quality in the paper cup sector where the product range is very wide. While 1 personnel controls 2 machines in manual paper cup collection, 2 personnel is sufficient for 20 machines in automatic packaging machines.

Request for a quote

YMCUP

Turkey

YM/KBM-DK150 series, which can produce 150 pieces per minute; It is suitable for the use of double-sided PE paper and helps you to produce quality with ultrasonic side bonding method. YM / KBM-150 series thanks to this model , we guarantee to increase your production capacity substantially .

Request for a quote

OPTIMA NONWOVENS GMBH

Germany

The modular design of the OPTIMA PAKSIS D5 allows customization for individual packaging needs. The stacker, fully equipped with two manual filling stations, is often used at the beginning of a diaper production. As the need for automatization rises, the base bagger can be added from the beginning or at a later point in time. Designed and manufactured in co-operation with Fameccanica Data S.p.A.Modular machine structure Sturdy design

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA WWM loads pre-packed wet wipes into PE bags. The machine concept is based on the LBV series which can be found in most of the countries around the globe. Packaging of paper hygienic products asks for minimum volumes at maximum speeds. From standard machines to high-performance packaging lines, machines from Optima Nonwovens are modular in construction and allowing to implement your special requirements. Secondary packaging of pre-packed wet wipes Handling of up to 4 rows possible Quick and easy change-over Cross direction feeding of pre-packed wet wipes

OPTIMA NONWOVENS GMBH

Germany

For packaging light incontinence products, high performance and a huge variety of packages are in demand. Adapted to these requirements, the OPTIMA HS/OSI bag packer and packaging machine offers maximum flexibility and ideal product protection. Stackers from Optima Nonwovens can synchronously accommodate the infeed of incontinence products from manufacturing machines. The products are counted by the stacker and arranged in pre-defined layouts. As the link to the packaging machine, the stacker quickly and gently supplies the products to the further packaging process. The OPTIMA OSI bagger delivers high outputs and can accommodate an extremely broad range of formats and larger packages. Modular machine structure Quick and easy change-over Multiple product rows possible Tilting cassette Premade polyethylene bags on wickets

Do you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA NONWOVENS GMBH

Germany

For packaging panty liners or sanitary napkins (regular or ultra thin), either flat or folded and wrapped, high performance and a huge variety of packages are in demand. Adapted to these requirements, only the best machinery offers maximum flexibility and ideal product protection. Fully automated machinery by the OPTIMA ON3/OS2 bag packer and packaging machine delivers the optimum process quality to deliver lowest cost per pack to our customers. Modular machine structure Multiple product rows possible Quick and easy change-over Premade polyethylene bags on wickets Tilting cassette

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA HS/OS7 bagger and packaging machine combines multiple decades of experience as the technological leader with unrivalled quality in machine engineering. The user’s individual requirements set the standard for how the packaging process is designed. With these high-performance machines, a multitude of new options are possible in the packaging process, for example for producing small packages at high speed. Multiple stack handling options Low count tilt module for low count bags Automatic lubrication system Motorized change-over High speed packaging

OPTIMA NONWOVENS GMBH

Germany

High packaging quality is always the crucial factor. The OPTIMA HS/OS3 bag packer and packaging provides the right packaging to best showcase logos and printing at the point of sales. The adjustable high compression further enhances quality and brings with it a number of advantages in logistics. Optima Nonwovens packaging machines are flexible: The machines can be adjusted quickly and easily for a large range of formats, format sets and modules. Fully automatic high-speed stacker for baby diapers Quick and easy change-over Quality gate Modular machine structure Designed for easy maintenance

OPTIMA NONWOVENS GMBH

Germany

Metal detection based on measurement of magnetic permeability Check-weighing process with industrial load cells Rejection pushers mounted on a separated frame to avoid any vibrations 5 separate servo driven belts Interface between TQCC and bagger included One HMI for metal detector, check-weigher and rejection Modular design for easy service

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA OSR bag packer and packaging machine can handle tissue products of all types, supporting all required roll product formations of kitchen towels and bathroom tissue in one or multiple layers. Optima Nonwovens machines and modules are designed to meet your specific requirements. Bathroom tissue and kitchen towel rolls can be packed on Optima equipment in pre-made polyethylene bags. This is how Optima Nonwovens has maintained its status as a leader in the industry. Full servo technology Modular machine structure Taylor made solutions to match individual requirements Small foot print Quick and easy change-over Single and double layer packages possible Premade polyethylene bags on wickets Point of sale packages Carry-handle possible Perforation for easy bag opening possible

OPTIMA NONWOVENS GMBH

Germany

Fully integrated counting, stacking, and packing machine for maximum process control and operability. The Packaging Machine OPTIMA PAKSIS A6 assures quick and easy installation and start up. Full servo technology for all operating units to provide maximum flexibility for diverse packaging requirements as well as quick change overs. The OPTIMA PAKSIS A6 offers a sturdy design and easy accessibility to the process units. All parts in contact with the product are designed in stainless steel or surface coated. Designed and manufactured in co-operation with Fameccanica Data S.p.A. Further information is also available at PAKSIS A6 - Breakthrough packaging systemsOptimized process control Full servo technology Quick and easy change-over Sturdy design

OPTIMA NONWOVENS GMBH

Germany

Fully integrated counting, stacking, and packing machine for maximum process control and operability. The OPTIMA PAKSIS D7 assures quick and easy installation and start up. Full servo technology for all operating units to provide maximum flexibility for diverse packaging requirements as well as quick changeovers. The packaging machine OPTIMA PAKSIS D7 offers a sturdy design and easy accessibility to the process units. All parts in contact with the product are designed in stainless steel or surface coated. Designed and manufactured in co-operation with Fameccanica Data S.p.A. Further information is also available at PAKSIS D7 - Breakthrough packaging systemsOptimized process control Full servo technology Quick and easy change-over Sturdy design

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA OS5 bag packer and packaging machine offers a new method for packaging tissue paper into either polyethylene bags or polyethylene film with the integration of reasonable product compression during the packaging process. The final packed product comes out as a nice, tight, compact package which is easy to palletize. Carton boxes for the secondary packaging are not needed anymore. The press capacity allows perfectly adapted product compression without any quality deficits. Due to the tight and compact film package, the number of truck loads required for transporting only the packaging material is significantly reduced as well as for the transport of the final package. Altogether, the new packaging method gives a high potential in cost saving on packaging material warehouse storage, shelf space and logisitcs and it is environtmentally friendly. Quick and easy change-over Premade polyethylene bags on wickets Carry-handle possible

OPTIMA NONWOVENS GMBH

Germany

Whether compressed large packages or sales packages with excellent visual and haptic quality, this segment is characterized by strongly varying requirements. Modular packaging machines such as the OPTIMA LS/OS8 can meet all these needs at the same time. Industry-leading outputs combined with very high machine reliability ensure productivity, while additional quality control functions for both, process and product, further sets these units apart from the competition. The OPTIMA OS8 bagger can be ideally combined with the OPTIMA LS stacker. Not only can an unrivalled range of formats be flexibly processed with this system; the integrated modules and additional (control) functions open up a new dimension of packaging process design. Modular machine structure Multiple product rows possible Stack turning possibility Quick and easy change-over Premade polyethylene bags on wickets

KMK-R LTD.

Bulgaria

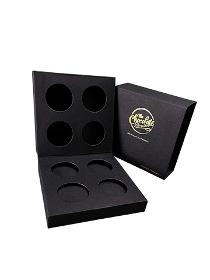

We are a European manufacturer and supplier of boxes for chocolate

Request for a quote

KMK-R LTD.

Bulgaria

We are a European manufacturer and supplier of cardboard boxes

Request for a quote

KMK-R LTD.

Bulgaria

We are European manufacturer of luxury folding boxes

Request for a quoteResults for

Cardboard - manufacturing machinery - Import exportNumber of results

31 ProductsCountries

Company type