- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high temperature insulators

Results for

High temperature insulators - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

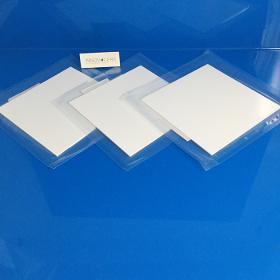

At present, conventional insulation materials have disadvantages such as low temperature resistance, low purity, gas release at high temperature, poor toughness, no insulation at high temperature, and easy to be corrosed. PBN insulation board can solve these problems. Main Features: 1. The maximum tolerance is 2300℃ in vacuum and 2700℃ in ammonia atmosphere; 2. High purity, high temperature does not release gas impurities (>99.99%); 3. Good toughness (hexagonal structure similar to graphite); 4. High temperature insulation (volume resistivity 3.11×1011 ω •cm); 5. Intensification of inert, acid, alkali, salt and organic solvent corrosion; 6. Low thermal conductivity in the DIRECTION of C can block the downward conduction of heat and reduce heat loss PBN Plate Applications: For vacuum, high temperature, MBE equipment and other fields of insulation gasket, gasket, support, etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

At present, conventional insulation materials have disadvantages such as low temperature resistance, low purity, gas release at high temperature, poor toughness, no insulation at high temperature, and easy to be corrosed. PBN insulation board can solve these problems. Main Features: 1. The maximum tolerance is 2300℃ in vacuum and 2700℃ in ammonia atmosphere; 2. High purity, high temperature does not release gas impurities (>99.99%); 3. Good toughness (hexagonal structure similar to graphite); 4. High temperature insulation (volume resistivity 3.11×1011 ω •cm); 5. Intensification of inert, acid, alkali, salt and organic solvent corrosion; 6. Low thermal conductivity in the DIRECTION of C can block the downward conduction of heat and reduce heat loss PBN Plate Applications: For vacuum, high temperature, MBE equipment and other fields of insulation gasket, gasket, support, etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

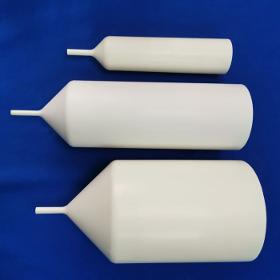

At present, conventional insulation materials have disadvantages such as low temperature resistance, low purity, gas release at high temperature, poor toughness, no insulation at high temperature, and easy to be corrosed. PBN insulation board can solve these problems. Name: high temperature resistant BN gold melting crucibles Borons Ceramic Main Features: 1. The maximum tolerance is 2300℃ in vacuum and 2700℃ in ammonia atmosphere; 2. High purity, high temperature does not release gas impurities (>99.99%); 3. Good toughness (hexagonal structure similar to graphite); 4. High temperature insulation (volume resistivity 3.11×1011 ω •cm); 5. Intensification of inert, acid, alkali, salt and organic solvent corrosion; 6. Low thermal conductivity in the DIRECTION of C can block the downward conduction of heat and reduce heat loss

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Porous ceramic plate is composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process. Applications of Alumina Porous Ceramic * Furnace work tubes * Kiln furniture, components & accessories * Thermocouple protection tubes * Heater Support Elements * High Temperature Electrical Insulators * Extreme temperature measurement components * Ceramic Laser components * High voltage electrical insulators

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA can improve material proportion and complete solution according to industry demand to achieve the best effect of customer use. Boron Nitride Ceramic Rod Characteristics: High thermal conductivity, pressed into various forms, used as high temperature, high pressure, insulation, heat dissipation components, such as aircraft, rocket engine nozzles. 2. Excellent thermal shock resistance and erosion resistance. It is used in Amorphous Ribbon Making and amorphous nozzles, three-dimensional printing metal powder diversion tubes, nozzles, etc. 3. High strength non-sticking, applied to various hot-pressing dies.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Pyrolytic boron nitride is a grade of hexagonal boron nitride. It is produced by chemical vapor deposition process to create its solid body and all the boron nitride crystals grow parallel to the surface of which the vapor is deposited on. Due to the nature of CVD process, PBN parts generally are requested the wall thickness not more than 3mm. PBN is also a good choice for extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process give this pyrolytic boron nitride almost perfect layered structure, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. PBN Ceramic Applications: -Crystal growth (VGF, LEC Crucible) -Molecular Beam Epitaxy(MBE) Crucible -MOCVD Heater -PBN Infrared Window -Traveling Wave Tube (TWT) (PBN Support Rod) -PBN Coating Graphite -High temperature, vacuum equipment insulator

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia ceramic disc plates are characterized by high toughness, high bending strength, high hardness and high wear resistance.Zirconia ceramics have a dimensional hardness of 11.5GPa, a density of 6.0g/cm3 and a compressive strength of 2100MPa. Zirconia ceramics are widely used as ductile ceramics with fracture toughness up to 8.0 mpAM1/2. Advantages: smooth surface (easy to clean), good toughness, impact resistance, high hardness, wear resistance, low thermal conductivity (heat insulation), generally no insulation and high temperature resistance Applications: machinery, optical fiber, cutting tools, medical, food, chemical, aerospace Ceramic material composition: - - 95%--99.99% Alumina (Al2O3) - - Silicon Carbide · Silicon Nitride - - TTZ: Magnesia partially stabilized Zirconia (ZrO2) - - YTZP: Yttria partially stabilized Zirconia (ZrO2) - - ZDY: Yttria fully stabilized Zirconia (ZrO2)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Due to the nature of the CVD process, PBN parts generally are requested a wall thickness not more than 3mm. PBN is also a good choice for the extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process gives this pyrolytic boron nitride an almost perfect layered structure, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. Pyrolytic Boron Nitride Applications: Crystal growth (VGF, LEC Crucible) Molecular Beam Epitaxy(MBE) Crucible MOCVD Heater PBN Infrared Window Traveling Wave Tube (TWT) (PBN Support Rod) PBN Coating Graphite High temperature, vacuum equipment insulator

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia Ceramic Screw and Bolts Ceramic screw and nuts refers to the ceramic screw is made of zirconia, alumina, silicon nitride and other materials of screw products,which has more stable physical stability and chemical stability, physical stability is mainly manifested in high and low temperature resistance, insulation, antimagnetic, wear resistance and other aspects; Chemical stability of the main surface in corrosion resistance, oxidation resistance. However, because it is a hard and brittle material, its mechanical properties can not be compared with metal materials. Of course, with the progress of material technology and the improvement of product structure,this gap is gradually narrowing. > Alumina Zirconia Ceramic Insulation Fastener Bolt And Screw > Thread Specification:M3-M24 > Screw cap:Hexagonal socket, flat headl > Plain Ceramic Hex M3 x 10mm Set Screwl M3 × 10mm > Screw cap:Hexagonal socket, flat headl > Plain Ceramic Hex M3 x 10mm Set Screwl M3 × 10mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Pyrolytic boron nitride is a grade of hexagonal boron nitride. It is produced by chemical vapor deposition process to create its solid body and all the boron nitride crystals grow parallel to the surface of which the vapor is deposited on. Due to the nature of CVD process, PBN parts generally are requested the wall thickness not more than 3mm. PBN is also a good choice for extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process give this pyrolytic boron nitride almost perfect layered structure, which leads to nisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. PBN Ceramic Applications: -Crystal growth (VGF, LEC Crucible) -Molecular Beam Epitaxy(MBE) Crucible -MOCVD Heater -PBN Infrared Window -Traveling Wave Tube (TWT) (PBN Support Rod) -PBN Coating Graphite -High temperature, vacuum equipment insulator

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

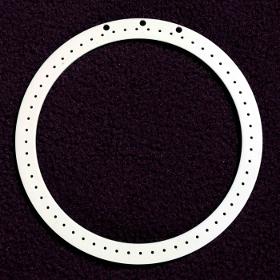

Mechanically durable and thermally shock resistant, PBN/PG heaters are unaffected by vibration under most conditions and can be tailored to thermal gradients for specific requirements. With an ultra-fast response and low thermal mass, PBN/PG heaters demonstrate a power output of 35 watts/cm 2 (225 watts/in 2 ) and higher.Size customization, please let me know the use temperature, current and voltage. -Crystal growth (VGF, LEC Crucible) -Molecular Beam Epitaxy(MBE) Crucible -MOCVD Heater -PBN Infrared Window -Traveling Wave Tube (TWT) (PBN Support Rod) -PBN Coating Graphite -High temperature, vacuum equipment insulator

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

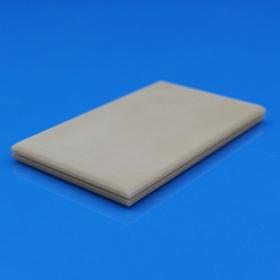

Product Name:Aluminum Nitride Ceramic Substrate, AlN Ceramic Sheet Application:Often used in electrical and electronic fields requiring heat conduction, heat dissipation, insulation, high temperature resistance,high voltage breakdown resistance, high thermal conductivity, good stability. Product specifications: Conventional models are TO-220, 247, 264, 3P Range thickness: 0.25mm, 0.385mm, 0.5mm, 0.635mm, 0.8mm, 1mm, 1.5mm, 2mm, 3mm Product Advantages: Aluminum nitride ceramics have excellent thermal conductivity (7-10 times of alumina ceramics),low dielectric constant and dielectric loss, reliable insulation performance, excellent mechanical properties, non-toxic, high temperature resistance, chemical corrosion resistance, and the thermal expansion coefficient of silicon is similar, as a new generation of ceramic materials, more and more by people Attention and attention.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as aluminum oxide (Al2O3), is the most mature and commonly used technical ceramics. With excellent electrical insulation properties together with high hardness and good wear resistance but relatively low strength and fracture toughness. Alumina content ranging from 80% to more than 99% according to different application. It's widely used in automotive, petro-chemical, fluid contro, material transfer, industry, electrical and electronic, semiconductor,etc... - High Temperature Ability - Abrasion Resistant - Wear Resistance - Chemical Resistance - Electrical Insulator - Corrosion resistant - High compressive strength - High mechanical Strength - Resists strong acid and alkali attack at high temperatures - Excellent electrical insulation properties - Decent thermal conductivity

Request for a quote

CHENGDU CHANG YUAN SHUN CO.,LTD.

China

High Silica Chopped Strand is a kind of inorganic fiber, which is drew and winded from glass marbles through a system of Na2O-B2O3-SiO2. Silica content≥94%, heat resistance temperature 1000℃, Usage High Silica Chopped Strand is widely used for the high temperature-resistance insulation materials, high temperature-proof materials, high temperature gas and liquid-filtration materials and the thermal insulation of spacecrafts and so on. Continuous Roving, Staple Roving and Chop Roving are included. Properties High Silica Chopped Strand has the good properties of high-temperature resistance, acid resistance, corrosion resistance, high insulation, low dielectric and so on. Specification High Silica Chopped Strand is a kind of roving which has staple length. It is used for strengthening bakelite, pressing high temperature-proof materials and so on. Length: 12mm, 50mm, 100mm, 150mm, 200mm. (3mm high slica shopped strand and 6mm high silica chopped strand are available now)

Request for a quote

CHENGDU CHANG YUAN SHUN CO.,LTD.

China

Quartz Fiberglass Fabric is made by quartz fiber yarn woven into a fabric with predetermined woven structures, such as plain, satin, twill and leno. Product Characteristics: ●High temperature use(1050℃ long term, higher temperature possible in case of short term exposure) ●Resistance to corrosion. ●Flexibility, dimensional stability. ●High temperature strength retention rate. ●Thermal shock resistance. ●Chemical stability. ●High electrical resistivity. ●Excellent wave penetration. Product Application: ●Rockets thermal protection system. ●Ablatives in military and aerospace (rockets nozzle, aerospace reentry aircraft). ●Radomes of missile, airplane, satellite, ship. ●Electromagnetic windows (jamming and anti-jamming equipment). ●Structural material for stealth technology (aircraft, naval ship, submarine). ●Wave penetration materials. Fiber Type: SiO2≥99.95% Heat resistance: 1200‘C Unit Weight 80~800 g/m2, Thickness: 0.08~0.

Request for a quote

CHENGDU CHANG YUAN SHUN CO.,LTD.

China

High silica fiberglass cloth is a kind of high temperature resistance, inorganic fiber. Its softening point is closely 1700 centi degree and it can be used under 900 centi degree situation for a long time and also be used for the rocket, the missile, the thermal insulation of spacecrafts, ablative materials, high temperature-proof materials and high temperature-resistant insulation materials, The content of SiO2 is more than 96% and the weight lost of ignition is less than 3%. It has two kinds of structure, plain weave and satin weave. The thickness is 0.1 to 1.5mm Product Characteristics: 1. Good chemical stability; 2. Good insulating property; 3. Good high-temperature resistance, acid resistance and erode resistance. 4. Low shrinkage and thermal conductive. Product Parameter: Technical Data Thickness(mm) 0.25±0.025 0.4±0.04 0.65±0.065 0.75±0.075 1.3±0.13 Weight 240±20,340±30,520±50,600±60,1050±100 g/m2 Width 92±2mm (without heat treatment )

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

High temperature insulators - Import exportNumber of results

17 ProductsCountries

Company type