- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- weigh

Results for

Weigh - Import export

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Accurate weighing system: This machine is equipped with a highly accurate weighing system that ensures precise filling of liquids into drums. Easy to operate: The semi-automatic filling machine is user-friendly and easy to operate. It requires minimal training for operators to handle it. High filling speed: The machine has a high filling speed that helps save time and increase productivity. Durable construction: The robust construction of the machine ensures its longevity and stability. It is made of high-grade stainless steel, which makes it resistant to corrosion. Flexible design: This semi-automatic machine is highly adaptable to different sizes and shapes of drums. It can accommodate a wide range of container sizes and volumes. Low maintenance: The machine is designed for ease of maintenance and requires minimal upkeep. The components are easily accessible for routine cleaning and maintenance. Safe and reliable: With safety features such as emergency stop buttons and door sensors

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The liquid product is first pumped into a reservoir tank, which is equipped with a load cell that measures the weight of the product. The operator then selects the desired weight and container size and places the empty pail on the filling platform. The machine will then dispense the product into the pail until the target weight is reached, at which point the machine will stop the flow of product and signal for the operator to remove the filled pail. The pail liquid weighing filling machine typically requires minimal operator intervention and can be programmed to fill a range of different container sizes and weights. This equipment provides a fast, accurate, and efficient method for filling pails with liquid products, making it an essential tool for many manufacturing and packaging operations. Features The system uses PLC, touch screen, safe and reliable Filling nozzle and pipe use quick coupling, convenient for removing and washing

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Some key features of the IBC weighing filling machine may include: High-precision load cells Automatic tare and gross weighing functions Product-specific filling programs Easy-to-use touchscreen interfaces Automatic valve control for precise filling Automatic IBC positioning and clamping A range of safety features, such as emergency stop buttons and safety guarding Overall, the IBC weighing filling machine is an excellent investment for any business that requires accurate and efficient filling processes for intermediate bulk containers.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Quantitive the liquid weight by a high quality weigher and weigher sensor High accuracy measurement system for different types of non corrosive liquid, corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

A pail liquid weighing filling machine is a type of equipment used in the packaging industry to accurately fill liquid products, such as chemicals, lubricants, and food ingredients, into pails or containers. This machine uses a weighing mechanism to ensure that the desired amount of product is delivered to each container. Application It is application for Food and chemical industries,quantitative filling of coating, solvent, chemical raw material Features: The system uses PLC, touch screen, safe and reliable Filling nozzle and pipe use quick coupling, convenient for removing and washing Automatic 2-shift filling with high accuracy The nozzle automatically lifts when reaching the target filling amount Gross or net filling mode is available Be able to set and store 30 groups of formula for use Free to set target filling amount in order to be convenient for different packing Filling with one button, easy to operate (manual operation mode available)

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The IBC weighing filling machine is a sophisticated piece of equipment that is designed to accurately fill intermediate bulk containers (IBCs) with a variety of different products. These machines feature high-precision weighing systems that ensure accurate measurement every time, and they are capable of liquid filling IBC Application Filling 60L, 100L, 200L and 1200Ldrums and filling IBC and POLY TANK Directly filling the drums stocked on the pallet Resin, solvent, and varnish products Food and beverage products such as liquid sugar, cooking oil, and resin Liquid chemical

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The can weighing and filling machine for liquid, can be both automatic and semi automatic, the automatic one is a inline type and multi heads from 2 heads to 12 heads depends on the capacity demand;the semi automatic one normally is with nonzzles numbers from 1 to 2. Application It is application for Food and beverage, cosmetics and personal care, agricultural, animal care, pharmaceutical, and chemical industries.,Also used in jelly, pudding, fruit juice, ice cream cup filling, yogurt cup filling, honey, curd, buttermilk filling, and shrimpkhand filling with a single or double filling nozzles. It suits for filling multi liquids, low investment, easy cleaning.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

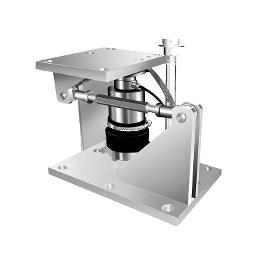

This weighing module GML-DHH5 bending beam load cell has the material option of alloy steel and stainless steel. It is compact and easy to install. The weighing capacity is from 10kg to 1000kg, which is usually used for hopper scale, belt scale, and batching scale. It can fulfill a wide range of industries that require precise measurements, avoiding product waste and saving costs.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

This weighing module with GML-DHH8B shear beam load cell has the material option of alloy steel and stainless steel. It is compact and easy to install. The weighing capacity is from 500kg to 2000kg, which is usually used for floor scale, batching silo, hopper scale, and industrial platform scale. It can fulfill a wide range of industries that require accurate measurements, avoiding product waste and saving costs.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

This weighing module with GML-DHH8Q shear beam load cell has the material option of alloy steel and stainless steel. It is compact and easy to install. The weighing capacity is from 500kg to 10000kg, which is usually used for floor scale, batching silo, and industrial platform scale. It can fulfill a wide range of industries that require accurate measurements, avoiding product waste and saving costs.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

This weighing module with GML-DHH8SB shear beam type load cell has the material option of alloy steel and stainless steel. It is compact and easy to install. The weighing capacity is from 500kg to 25000kg, which is usually used for floor scale, batching silo, hopper scale, and industrial platform scale. It can fulfill a wide range of industries that require accurate measurements, avoiding product waste and saving costs.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

This weighing module with GML-DHH8SB shear beam type load cell has the material option of alloy steel and stainless steel. It is compact and easy to install. The weighing capacity is from 500kg to 25000kg, which is usually used for floor scale, batching silo, hopper scale, and industrial platform scale. It can fulfill a wide range of industries that require accurate measurements, avoiding product waste and saving costs.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

B103B-12T is a weighing and batching equipment with intermittent feeding and continuous discharging. During the operation, it can discharge constantly with uniform mixing material and automatic flow correction. The flow rate can be adjusted from 0.5t to 12t per hour. The accumulated accuracy is under 0.1%. It can be widely used in food processing, chemical material processing, and other flow-batching applications.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

GM7702, a digital weighing transmitter with the standard dimension, is suitable for mounting on DIN rail in many industrial fields. Small size and flat compact design make it ideally integrate with whole weighing sector. Due to its high practicability, stability and easy operation, GM7702 can be widely applied to the industry of feeds, chemical, concrete and bitumen mixing, metallurgy smelting, etc..

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

GM9907 is a general-purpose weighing controller series that is designed to control automatic packing machines. GM9907-LD with dual hoppers is for the double scale packing machine. The brand new GM9907-L2 has 5 models to complete different functionality(with/without hopper, bulk scale, valve port, PLC). This series can be widely used in the industries of feed, grain, seed, and chemical and so on.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

M02, a compact yet powerful panel-mounted weighing indicator designed to meet all basic weighing needs, whose reliability and digital filtering show the ability to perform under interference in industrial environments. There are over 100,000 products in use with negligible repair rates. With high reliability, accuracy and response speed, M02 is customized for dynamic weighing systems.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

The GMT-P1 is a panel-mounted weighing transmitter that offers exceptional reliability, advanced filtering, and tested ability to perform stably under the interference of harsh industrial environments. It is customized for dynamic weighing systems with the highest demand for reliability, response speed, and accuracy.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Automatic drum liquid weighing filling machines are designed to fill drums with liquids using weight sensors and speed control technology. Some of the features of these machines include: Accuracy: These machines use weight sensors to ensure the accurate and consistent filling of drums with liquids. Speed control technology: The machines are equipped with speed-control technology, which allows for the precise and efficient filling of drums with liquids. Ease of use: The machines are designed to be user-friendly, with easy-to-use controls and quick changeover times. Versatility: These machines can handle a wide range of liquids from oils, solvents, chemicals, and other high-value liquids. Safety: The machines have built-in safety features, such as emergency stop buttons and guarding, to ensure operator safety. Low maintenance: Automatic drum filling machines are often designed for low maintenance

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

For some highly corrosive liquid products, this machine can adapt PTFE pump, PTFE hose and sealing material, so as to avoid the corrosive of the machine 2. The parts in contact with the liquid conform to the GMP standard. When filling, the filling head extends into the bottle and the bottle is sealed to ensure that the liquid does not foam and overflow, and the liquid level in the bottle is consistent. 3. The filling head has the function of sucking back, and there is no dripping phenomenon. The bottle is not in place and not filled, ensuring misoperation and keeping the work area clean. 4. This machine has only one filling pump, one top tank and one side stand tank which can be equipped with 2~20 filling heads, and the output and filling volume can be adjusted if need. More information: When filling, the filling head presses against

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NPACK drum liquid weighing filling machine is a piece of packaging equipment used to weigh and fill liquids into 100L to 300L drums. A weighing platform (weighing system), a filling nozzle or several filling nozzles, a control panel, and a roller conveyor system comprise the majority of the equipment. The weighing platform measures the weight of the drum before and after filling to ensure that the correct amount of liquid is filled. The filling nozzle is used to transport liquid by gravity or pump from a storage tank or container to the drum. The operator can set and monitor the required weight of the filled drum, as well as regulate the filling process, using the control panel. The conveyor system is used to move the drums to and from the filling station. Main Applicaton fields: Oil Solvent such as thinner Liquid sugar Cooking oil and resin Resin Food and beverage such as soy sauce Paint and varnish Other liquid chemicals

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Net weight filling machines use a weigh scale platform to monitor the weight of product as it is filling into a bottle or container. Net weight fillers are well suited for large container filling applications. This type machine is used for 5kg -30 kg,and 50KG to 300KG, and IBC system liquid filling. both of gravity filling or pump feeding liquid system with weight scale under filling nozzle or under the conveyor to assure filling accuracy. It can finish a series of operations automatically, such as bottle inlet, weight filling, and bottle outlet. Especially for SL, edible oil lubrication. it is a nice choice for foodstuff, pharmacy, cosmetic and chemical industries.Linear type machine, can be made with 2/4/6/8 filling nozzle for different filling capacity.

Request for a quote

PAIBON DEVELOPMENT CO.,LTD

China

Body fat scale BT2298 with bluetooth function and max up to 180kg Size: 300x300x23mm LCD display Battery: 2x1.5V AAA

Request for a quote

PAIBON DEVELOPMENT CO.,LTD

China

Digital kitchen scale K7912 in glass max 5000g size: 205x165x17mm LCD display battery: 1x3V CR2032 button cell

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

100% in-line control weight capacity CW-60K, an automatic checkweigher integrated the new dynamic weighing technology offers a high precision solution in weighing system to a wide range of industries, such as food, grain, fertilizer and cement, especially to logistics regarding to heavy load production line. Weighing range: 100g-60kg Speed: ±10g Accuracy: 60pcs/min

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

GMC-P7 weighing controller is designed for dynamic weighing/packing/batching applications, widely used in grain and seeds, feeds, rubber and plastic, and the chemical industry. There are multi-software for different applications: 1. Single hopper packing 2. Double hopper packing 3. Reduce weight method packing 4. Bulk scale 5. Batching scale

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

OIML R76 approved GMT-X1, a DIN rail-mounted weighing transmitter for industrial automation, can be used in various system weighing applications, such as weight checking, loss-in-weight, liquid filling, batching, vessel and silo weighing, etc. Through Bluetooth, it can be connected to Weasy App for configuration and monitoring. Hardware Configuration: 1. Standard: RS4851 + RS485/RS232(Selectable) 2. Hardware Option1: 3 Input 5 Output or 3 Input 4 Output relay (Optional) 3. Hardware Option2: RS485+16bit Analog or 2 Input 4 Output 4. Hardware Option3: Modbus TCP or Ethernet/IP or Profinet (Hardware Option1,2,3 can be selected at the same time) 5. Bluetooth Communication

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

GMT-X4 is a DIN rail-mounted weighing transmitter with four-channel. When one of the four channels' load cells is damaged, GMT-X4 will automatically identify and give an alarm by displaying the alarm message on the screen. It has the characteristics of compact design, stable performance, and easy operation, which can be used for various weighing applications, such as weight checking, loss-in-weight, liquid filling, batching, vessel and silo weighing, etc. Different configuration choices, a variety of combinations; Standard: ① 4-channel of 6-wire load cell interfaces; ② RS485&RS232; ③ 4 Input 8 Output transistor I/O; Option1: Modbus TCP /IP or EtherNet/IP or ProfiNet or EtherCat; Option2: 4 analog output; Option3: 1CAN interface; (Option1,2,3 can be selected at the same time)

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

This weighing module with GML-DHH4ZS canister load cell has the material option of alloy steel and stainless steel. It is compact and easy to install. The weighing capacity is from 10000kg to 50000kg, which is usually used for floor scale, truck scale, railway scale, silo scale, and tank scale. It can fulfill a wide range of industries that require accurate measurements, avoiding product waste and saving costs.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

GMT-X4 is a DIN rail-mounted weighing transmitter with four-channel. When one of the four channels' load cells is damaged, GMT-X4 will automatically identify and give an alarm by displaying the alarm message on the screen. It has the characteristics of compact design, stable performance, and easy operation, which can be used for various weighing applications, such as weight checking, loss-in-weight, liquid filling, batching, vessel and silo weighing, etc.

Request for a quoteResults for

Weigh - Import exportNumber of results

42 ProductsCountries

Company type

Category

- Weight and mass - measurement and regulation instruments (11)

- Bottling and filling - machinery and equipment (11)

- Fuel cells (6)

- Measurement - Equipment & Instruments (5)

- Measurement and control instruments (4)

- Packing and packaging - machinery and equipment (3)

- Weighing and dosing equipment (2)

- Fishing equipment (1)

- Furniture for kitchens (1)