- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cold extrusion of steel and metals

Results for

Cold extrusion of steel and metals - Import export

MODULUS METAL

Turkey

Modulus Metal has ISO certified supplier base and our partner suppliers are experienced in automotive, aerospace, agricultural, railway, and industrial machinery manufacturing for many years.

Request for a quote

TABELARAIZ

Portugal

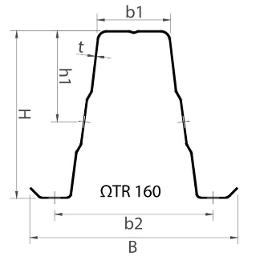

Omega sections characterised as ΩTR60, ΩT110, ΩTR160, ΩTR210, ΩTR260; Profiles sold in EN 10346 steel: Hot-dip galvanised Z:200, 275 | Zin+Mag:175, 250; Drilling is carried out according to the position indicated by the customer.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Special machines from Schmale Maschinenbau are equipped with an intelligent combination of technologies. The plant shown above is used to manufacture reinforcement items from solid material with a diameter of 20mm for the building industry. Servo-electric units such as bending slides, presses and finger benders are combined into customer-specific solutions for the production of individual items that can not be produced on standard machines. Schmale offers special machines for wire, tube and strip processing. You can watch various special machines for the production of different forming articles on our YouTube channel. https://www.youtube.com/channel/UCziuQiA3kXBVfH4ecLxQ2JA/videos

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in Turning Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper

Request for a quote

MARXAM PROJECT

Poland

Metal Sheet stamping is one of the basic plastic forming processes. In our company, we perform cold variance of stamping sheet metal using hydraulic presses. Experience in the selection of material, as well as the design and manufacture of the working tool allows us to carry out the metal stamping process while maintaining the appropriate technological parameters. The stamping process is one of the main methods of shaping the material that can be used to implement various projects. Sheet metal pressing offered by Marxam Project can also be easily used in industrial metal stamping. Our services extend to both individual customers, as well as larger orders for industrial use.

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage system -Emergency stop button -Moving saw protection guard -Motor protection kit -Burr-free cutting -Precise cutting by centering the material with the double-sided pneumatic vice control -Comes with a stop rod for repeatable cuts

Request for a quote

MECHASYS GMBH

Germany

lasercutted sheets bended in hard-tool for mid-range batches, high flexible, batches from 1.000 - 50.000 parts

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage systems -Emergency stop button -Safety regulations, according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Automatic cutting by centering the material with the double-sided pneumatic vice control -Comes with a stop rod for repeatable cuts -Process counter -Hassle-free performance

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage systems -Emergency stop button -Safety regulations, according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Automatic cutting by centering the material with the double-sided pneumatic vice control -Comes with a stop rod for repeatable cuts -Process counter -Hassle-free performance

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage system -Emergency stop button -Moving saw protection guard -Motor protection kit -Burr-free cutting -Precise cutting by centering the material with the double-sided pneumatic vice -control -Comes with a stop rod for repeatable cuts -Hassle-free performance

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -Comes with a stop rod for repeatable cuts -24 V low voltage system -Emergency stop button -Safety regulations,according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Hassle-free performance

Request for a quote

EURASIA METAL GMBH

Germany

Production standart : EN 10051 FOR HR MATERIALS - S235 JR, S275 AND S355 QUALITIES EN 10139 FOR CR MATERIALS - DC 01 , ST 12 QUALITIES EN 10025 – 1

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD MF 500 - Allrounder-machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the Handformer HF 100. This Multiformer MF 500 GL 2 consists of: English wheeling machine MF 500 + planishing hammer GL 2 Optionally available with a Handformer HF 100 for shrinking (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Universal forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming and straightening. The many special features of the Kraftformer KF 675 Magnum include stroke speed preselection and stored machining programmes for reproducible results. The Kraftformer KF 675 Magnum is capable of machining large steel components with a sheet thickness of up to 6 mm. A single Kraftformer is all you need to bend profiles, form sheet metal, produce new parts, and repair or rework workpieces with high precision. For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). • Preselection of stroke speed • Adjustable return position • Stores up to 25 user-defined machining programmes • Reproducible results • Tool check • Electronic fault diagnosis • Servo motor-driven machine Max. forming capacity Steel 400 N/mm²: 6.0 mm Aluminium 250 N/mm²: 6.0 mm Inox 600 N/mm²: 4.0 mm

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD Kraftformer KF 170 PD - Universal forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming, straightening, punching, notching and clinching. The Kraftformer KF 170 PD with pneumatic drive is the most compact of all ECKOLD Kraftformers. The machine is designed for single or continuous stroke operation for forming steel sheets with a thickness of up to 2 mm. Operated in single stroke mode, the KF 170 PD is the ideal machine for reworking and adjusting tasks. It can be used for punching, notching and clinching. In continuous mode, the KF 170 PD allows for fast and easy forming. In single stroke mode, it caters for precision hole punching, clinching and reworking! For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Max. forming capacity Steel 400 N/mm²: 2.0 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.5 mm Contact us for a customised offer, tools included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the tried and tested planishing hammer GL 2. This Multiformer MF 500 MAX consists of: English wheeling machine MF 500 + Handformer HF 100 for shrinking For our Handformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Optionally available with a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

MF 800 - A complete workshop in one machine. The MF 800 MultiFormer is the ingenious multi-functional machine for stretching, planishing, driving and shrinking of metal sheets. This sophisticated wheeling machine is ideal for working on medium to large size work pieces: such as motorbike tanks, fenders, hoods, bonnets, door panels, etc. The compact machine comes fully equipped with castors so that it can be moved to any location in the workshop. • Large tool shelves • Wheels and wheel supports rotatable by 90° • Roller angle adjustable • Large selection of optional accessories • Quick tool change This Multiformer MF 800 KIT 2 consists of: English wheeling machine MF 800 and Handformer HF 100 for shrinking Optionally available with a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 3.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ECKOLD GMBH & CO. KG

Germany

ECKOLD Kraftformer KF 324 - Universal forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming and straightening. The cult-classic among the Eckold machines, the ECKOLD Kraftformer KF 324, is the cheapest motor-driven machine of the Kraftformer series. It is also known as ECKOLD Piccolo and has been designed for a long service life. Metal workers all over the world are delighted with this machine, as it works perfectly for many decades. With the ECKOLD Kraftformer KF 324, the press force is controlled by means of a hand wheel. This model is designed for the forming of steel sheets up to 2 mm in thickness. For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Max. forming capacity Steel 400 N/mm²: 2.0 mm Aluminium 250 N/mm²: 2.5 mm Inox 600 N/mm²: 1.5 mm Contact us for a customised offer, tools included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Universal forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming and straightening. The ECKOLD Kraftformer KF 340 is part of the medium-force Kraftformer range with motor drive. Depending on the workpiece to be machined, the operator can adjust the number of working strokes to any value between 220 and 600 strokes per minute continuously. Low speeds are particularly suitable for shrinking, stretching and for straightening and precision finishing. Thanks to the high stroke rate, the machine is also widely used for doming (dishing) and planishing, boosting productivity. This Kraftformer is capable of machining steel sheets of up to 3 mm in thickness! For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Max. forming capacity Steel 400 N/mm²: 3.0 mm Aluminium 250 N/mm²: 4.0 mm Inox 600 N/mm²: 2.0 mm Contact us for a customised offer, tools included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

MF 800 - A complete workshop in one machine. The MF 800 MultiFormer is the ingenious multi-functional machine for stretching, planishing, driving and shrinking of metal sheets. This sophisticated wheeling machine is ideal for working on medium to large size work pieces: such as motorbike tanks, fenders, hoods, bonnets, door panels, etc. The compact machine comes fully equipped with castors so that it can be moved to any location in the workshop. • Large tool shelves • Wheels and wheel supports rotatable by 90° • Roller angle adjustable • Large selection of optional accessories • Quick tool change This Multiformer MF 800 KIT 1 consists of: English wheeling machine MF 800 Optionally available with a Handformer HF 100 for shrinking and/or a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 3.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD MF 500 - Allrounder-machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the tried and tested planishing hammer GL 2 and/or the Handformer HF 100. This Multiformer MF 500 EW consists of: English wheeling machine MF 500 Optionally available with a Handformer HF 100 for shrinking and/or a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming and straightening. The electronic display of the control system visualizes operations, fault tracing and indicated maintenance rates which ensure an optimum machine utilization. Storable processing programs allow repeatable results. This Kraftformer model is particularly recommended for the forming of sheet metal in the industrial metal construction sector as it is capable of machining large steel components with a sheet thickness of up to 3 mm. For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). • choice of two preselectable stroke speeds • adjustable reverse position • 4 storable processing programs • repeatable results • electronic display/fault tracing Max. forming capacity Steel 400 N/mm²: 3.0 mm Aluminium 250 N/mm²: 4.0 mm Inox 600 N/mm²: 2.0 mm Contact us for a customised offer, tools included!

Request for a quoteResults for

Cold extrusion of steel and metals - Import exportNumber of results

23 ProductsCountries

Category

- Forming - steels and metals (12)

- Cutting - steels and metals (5)

- Bending - steels and metals (3)

- Turning - steels and metals (2)

- Bending machine tools (1)

- Cold rolled steel strips (1)

- Galvanization - steels and metals (1)

- Shaping - steels and metals (1)

- Stamping - steels and metals (1)

- Steel, carbon (1)

- Steels and metals - forming and cutting (1)