- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyor systems- closed

Results for

Conveyor systems- closed - Import export

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple Jar and caps size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 6 diving filling nozzles Customizable jar filling spaces HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system Caps feeding section with vertical conveyor system Capping system Closing system. Servo conveyor system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple Jar and caps size, types and shapes Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: 6 diving filling nozzles Customizable jar filling spaces HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system Caps feeding section with vertical conveyor system Capping system Closing system. Servo conveyor system.

Request for a quote

FEMIA INDUSTRIE

France

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

FEMIA INDUSTRIE

France

Installed at the line infeed of granular products such as peas/flageolet beans, it extracts small size waste and sticky waste as well as large waste. Machine primarily comprised of a drum of which the perforations of the final section are adapted to the product processed. Continuous cleaning of the machine thanks to its system of brushes and scrapers. Products to be processed exit from the 3rd section of the drum. Collection and discharge of waste thanks to a conveyor inside the drum (except for small size waste at the beginning of the machine).

Request for a quote

FEMIA INDUSTRIE

France

Provides receiving, storage and feeding of the product downstream. The dimensions can be adapted according to the capacity of the line and the means of unloading raw materials used. A conveyor belt with high sides which provides the storage and transport of products.

Request for a quote

ROBINSON CO.

Turkey

The Conveyor used in grain, creals and food processing plants in the transport unit. Tube Conveyor is used for the horizontal transporttation of products in flour plants. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Manual Sorting Belt Conveyor is used in those places where bulky luggage is collected centrally from the various luggage lines and prepared for inspection. As a special solution, it can be adjusted to a huge range of conditions, such as conveyor height, positioning of the control system, belt lengths, conveying direction or conveying speed. The heart of the sorting belt is formed by two plastic link conveyors, which are characterised by a very smooth and wearresistant surface and have a far longer life span than roller tables that have been used in the past. The individual pieces of luggage are transported to a certain position by the electronic link conveyor and then manually pushed off in the direction of the conveyor. This procedure makes the work of airport personnel considerably easier.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a capacity of up to 2500 pieces of baggage per hour, strength and resilience are fundamental. The Motion06 Vertical Sorting Unit Belt Conveyor is used for the distribution and merging of baggage and general cargo between two or three levels. The belt conveyor incorporated into the Vertical Sorting Unit is height adjusting using a top of the line lifting system with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. It is also possible to use it in flight baggage systems with a container system. The belt conveyor is replaced by an appropriate conveyor element for this purpose. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

An innovative new design to allow you to easily sort packages and parcels during your manual sortation process. The unit can also be supplied with an integrated weight scale unit with a digital display. Adjustable Height Telescopic leg sections to raise or lower the conveyor bed height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. Castors with Brakes 127mm x 38mm Swivel Castors allow easy movement. Castor brakes lock both wheels and swivel simultaneously while the conveyor is in use.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestConnect system is designed to provide rapid assembly of conveyor solutions for changing workplaces. Systems can be easily configured and reconfigured as required to suit your immediate requirements. With a simple 240v power supply and latching connections, the engineering requirement is minimal. Continuous Duty Multiple Drive Motors 20 to 120 Vdc geared motors. Adjustable speed is from 2 to 36 metres per minute. Start/ Stop controls at both ends. Adjustable Height Telescopic legs to raise or lower the conveyor height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. 50mm Roller Heavyduty precision bearing rollers on 12mm axles for greater durability.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The MaxxReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction MaxxReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction BestReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Designed to expand, contract and move easily, the BestFlex200 is a selftracking, gravity skate wheel conveyor that has a per linear foot capacity of 300 Kilograms. This unit is engineered to handle multisized cartons in low to medium volume applications. The allsteel construction provides unmatched structural integrity, whether the conveyor is extended, compacted or configured in simple or compound curves. Adjustable inner legs vary the height to achieve gravity flow. The BestFlex200 is the choice for use in retail storelevel applications, packaging areas, assembly lines and in low volume shipping and receiving departments. SelfTracking Cartons follow the path of the conveyor without using engineered curves. Adjustable Height Telescopic leg sections are used to raise or lower the conveyor height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestFlex Roller is excellent for handling oddshaped boxes, bags and lowgrade cartons in low to medium volume applications. Designed to expand, contract and move easily, the BestFlex Roller is a selftracking, gravity roller conveyor that has a per linear foot capacity of 220Kg per linear metre. The allsteel frame construction provides unmatched structural integrity, whether the conveyor is extended, contracted or configured in simple or compound curves. It is the best choice for moving items without a flat, solid surface. SelfTracking Cartons follow the path of the conveyor without using engineered curves. Adjustable Height Telescopic leg sections are used to raise or lower the conveyor height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. 40mm Side Plate Aluminium alloy construction features a ribbed design for added strength. Assembled with bolts and locking nuts. Castors with Brakes 127mm x 38mm Swivel Castors allow easy movement.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Flexible powered conveyors provide maximum productivity in shipping, transportation and packaging applications where usability and adaptability are most needed. With its innovative design, the PowerFlex15 powered roller conveyor requires less storage space when fully retracted and can service multiple docking doors for maximum productivity. By powering the conveyor, any package size can be moved, any distance at variable rates of speed. This powered conveyor has a capacity of 150Kg per linear metre. The PowerFlex15 also features an easy and quick way to change out the drive belts giving you added durability and less maintenance downtime. Continuous Duty Multiple Drive Motors Line speed is adjustable from 0 to 36 metres per minute. Start/stop controls at both ends. Self Tracking Cartons follow the twists and turns of the conveyor path without using engineered curves. Adjustable Height Telescopic legs to raise or lower the conveyor bed height.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

PowerFlex is designed to be a robust, flexible and reliable conveyor solution for almost any operation requirement. Using its integrated handles and intuitive design, the conveyor can be contorted and shaped to fit into infinite environments. Its braked castors, 240v power supply and renowned latching connections make it an incredibly userfriendly piece of equipment. The PowerFlex SmartFlow platform differs from traditional PowerFlex with its distinct controls functionality. SmartFlow allows for multiple flow control options within one conveyor. Different user operations call for different equipment functionality – SmartFlow puts them all in one place. The selector switch is mounted on the unit’s selfcontained control box, which allows you to switch from 5 varying flow control modes. See below for further details. PFSF also retains all PowerFlex’s renowned functionality – simply connect multiple SmartFlow units to create whatever length is required.

Request for a quote

GSW SCHWABE AG

Germany

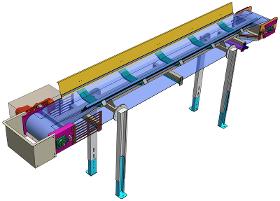

with its compact design using a structural aluminum profile, conveyor system is ideally suited for continuous duty applications in multiple shift environments. using the benefits of modular construction, this conveyor can be readily integrated into new or existing equipment or be used as a freestanding conveyor for bulk handling and loading aplpications. inclination smoothly adjustable steplessly fourwheel drive, 2 steering wheels with parking brake 13 collector rollers, height 20 mm transport cover PUeven, 2 layers, to be used at temperatures from 30 120°C, oiland grease resistant, antistatic funnel (attachment), aluminium anodized drop area pivotable clip/aluminiumclosed bar system suitable for materials to be conveyed from a thickness of 2 mm on for lower thicknesses of materials to be conveyed, allaround corrugated material edges made from celloflex. This reduces the usable width of the material by approx. 70 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HO-MA GMBH

Germany

Its flexible design makes the flush-grid belt conveyor particularly compact and its curve radius can be adjusted.

Request for a quote

NOVELTY STEEL

Turkey

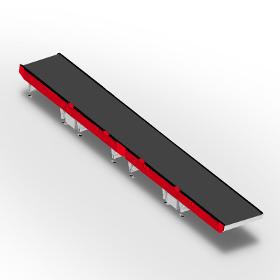

Belt conveyors used for handling bulk solids utilize rubber-covered belts, where the inner carcass of the belt provides the necessary strength to pull and support the conveyed load. The carcass is shielded from damage by layers of rubber, which may vary in thickness depending on the specific application. Belt conveyors exhibit the capability to transport materials across a broad range of rates, spanning from just a few kilograms per minute to several thousand metric tons per hour. ndard troughing angles are commonly set at 0°, 20°, 35°, and 45°. The angle of surcharge is a material-specific property and can be compared to the dynamic angle of repose. The power requirements for belt conveyors hinge on various variables, including the conveyor’s profile, the type of drive-pulley arrangement, belt tensions, belt speed, and idler spacing.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

BestReach Gravity Telescopic Boom Conveyors will load most items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load times significantly whilst improving operator working conditions. These units are typically used in conjunction with sortation systems or feeding conveyors. Construction BestReach Gravity Telescopic Boom conveyors are built to the highest standard with a thick steel main case providing one of the strongest, most robust, conveyors of its type on the market. Drop Down Package Stop A package stop is fitted to the end of the last stage of the conveyor but can be latched up or down as required. Spring Assisted A torsional coil spring is fitted between the extending stages to aid smooth extension and retraction.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Whether straight, inclining or declining – the Motion06 Belt Conveyor transports luggage, packages and general cargo across any distance. As a modular system, the conveyor belt is suitable for a wide variety of requirements. The basic model includes the head drive or central drive, reversing station, normal round, pass round and support or suspension modules. The transitions between the individual conveyors are fitted with individual transition sheets. The tensioning station at the head drives and reversing stations is tensioned from both sides on the basic model. The tensioning station on the centre drives is tensioned on one side. SBC – 080/112/157. Structural Lengths Short structural lengths of approx. 600 mm conveyor length and, for example, belt width of 1.000 mm possible. Any Height Requirements Low overall height possible with integrated belt tracking device. Floormounted version or suspension from the ceiling incl. individually adjustable height and angle are also available.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a conveying speed of up to 3.0 m/s, flexibility and hardiness are also demanded of the curves. The area of application for the Motion06 Curved Belt Conveyor is in the continuous or clocked transportation of pieces of luggage and packages with changes in direction. When developing the Curved Belt Conveyor, the highest priority was given to the ‘small space requirements’ and a wide range of standard measurements or customerspecific measurements for integration into new or existing systems. The entire product range is a modular design and is designed based on stateoftheart technology. A consistent appearance for the operation of a wide variety of weight classes and product sizes is available worldwide. Structural Lengths Short structural lengths of approx. 600 mm conveyor length and, for example, belt width of 1.000 mm possible.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

From 0 to 3.0 metres per second. The Motion06 Strip Belt Merge puts baggage on the right track like no other. It is exactly this construction – the design as an adjoining merge point – that can provide the fundamental advantage of operational safety. In the case of one strip being damaged, the system continues to work flawlessly. In connection with a belt deflector, the merge can also be used to transfer baggage from different angles. Simple Installation Ultrasimple adjustments for required installation conditions. Various Designs Horizontal or sloping design. Conveyor Casing Casing can be steelcoated or stainless steel. Low Maintenance Lowmaintenance friction drive Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation.

Request for a quote

ILK IHRACAT AS.

Turkey

Our conveyor systems are designed to be the heart of Industry 4.0, the fourth industrial revolution that is transforming the manufacturing landscape. Industry 4.0 is characterized by the integration of digital technologies and automation into the manufacturing process, resulting in increased efficiency, improved productivity, and reduced costs. Our conveyor systems are at the forefront of this revolution, incorporating advanced technologies such as Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML). These technologies enable our conveyor systems to collect and analyze real-time data, optimize production processes, and make intelligent decisions. With IoT capabilities, our conveyor systems can communicate with other machines and systems in the production line, creating a seamless and interconnected network. This allows for real-time monitoring and control, ensuring that any issues or bottlenecks are quickly identified and addressed.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

The necessity to spread/separate or converge products while they are moving on a process belt conveyor is a major requirement for a wide range of food, confectionery and industrial applications. In many cases this allows processors to run narrower conveyors saving factory floor space. Coating processes also benefit by separating product and reducing rejection rates.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Field-proven and dependable Flex-Turn® units gently convey products in process around corners while maintaining proper product alignment. They offer the tightest level transfer and smallest inside turning radius available with an open mesh belt. Smooth, non-collapsing product handling minimises potential damage to delicate products. The compact design solves tight production line space problems.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Wire Belt offers a range of straight conveyors designed to ensure efficient operation, improved belt life and maximum cleaning ability. Our straight conveyors feature an open construction with the belt being supported on food grade high density blue polyethylene wear strips clipped to the stainless steel framework. All of our conveyors are suitable for use in hygiene-sensitive environments common to the food and pharmaceutical industries.

Request for a quote

OMS MEKANIK OTOMASYON SISTEMLERI SANAYI TICARET LIMITED SIRKETI

Turkey

Conveyor can be manufactured in desired dimensions and dimensions. Conveyor provides simple transportation of products to be transported or shipped from one place to another. We produce conveyors according to the type, weight and quantity of the products It works with the motor system and the speed can be adjusted. Conveyor belt selection is made according to the characteristics of the products. Systems 7-8 bar air system is required. Made of polycarbonate plastic food and chemical resistant or cloth resistant non-slip pad. Products can be manufactured from 316-304 or painted sheet products depending on the situation

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For industries in waste treatment and recycling, we offer conveyor systems that include: Roller conveyors, Sliding conveyors, Speed conveyors, Chain conveyors, Transporting conveyors, Spiral conveyors, Bucket elevators, Bunker conveyors

Request for a quoteResults for

Conveyor systems- closed - Import exportNumber of results

65 ProductsCountries

Company type

Category

- Conveyor systems (47)

- Conveyor belts (9)

- Heating, domestic - installations and equipment (6)

- Bottling and filling - machinery and equipment (2)

- Agriculture - Machines & Equipment (1)

- Conveyors, overhead and floor (1)

- Erection and dismantling of industrial plants (1)

- Flour-milling (1)

- Food Industry - Machines & Equipment (1)

- Food industry - machinery and equipment (1)

- Grids, gratings and wire mesh (1)

- Machine tools, metal shaping - parts and accessories (1)

- Plastics - machines and material for industry (1)