- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyor systems

Results for

Conveyor systems - Import export

FEMIA INDUSTRIE

France

Today, waste management has become a genuine challenge in sustainable development and yield on fruit and vegetable processing lines. Femia provides solutions aimed at extracting only the waste, without affecting the processing of good products. According to a model based on green and circular economy, they are then brought together, recovered and recycled.We design, along with you, a logic for customised waste recovery, according to your material recycling objectives (animal feed, farm use with or without composting), energy (methanisation) or incineration with energy recovery. We integrate the recovery approach right from the design phase for your production lines in order to allow your conveyors progressive and facilitated recovery of wastes all throughout theproduction lines.

Request for a quote

FEMIA INDUSTRIE

France

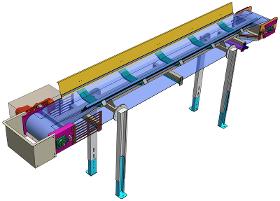

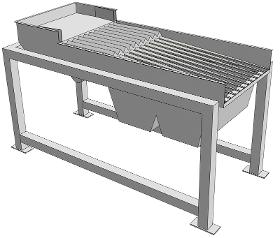

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

FEMIA INDUSTRIE

France

Its unique, high performance design allows the full release of the smaller diameter green beans between the sorting bars. A very precise range of settings ensures product homogeneity, especially on extra fine sizes. The T43L and T46 models sort green beans into 2 sizes. The T44 model sorts in 2 3 sizes. For better user comfort, the T46 can be equipped with a remote adjustment system.

Request for a quote

FEMIA INDUSTRIE

France

Extracts the waste that is denser (stones, clumps of soil, various objects etc.) than the processed product. Machine primarily comprised of a destoning tank, a pump that allows for the sustentation of the processed products and a vibrating draining separator. Recovery in a settling tray under the separator and filtering of the water with a wire screen. The upper screens of the vibrating separator can be removed and are perforated according to the product processed. Continuous removal of heavy waste in a chamber with 2 controlled valves and its control box.

Request for a quote

FEMIA INDUSTRIE

France

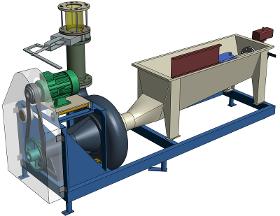

Chops maize waste in particular to facilitate future valuation. Machine mainly consisting of a heavy drum (high inertia) and multiple hammers fixed regularly on the cylindrical part of the drum. Several models available depending on the capacity of the product to be shredded. Carrying structure to be added under the equipment to facilitate the exit of the crushed product. Adapted to the architecture of the line and the constraints of the building. Translated with www.DeepL.com/Translator (free version)

Request for a quote

FEMIA INDUSTRIE

France

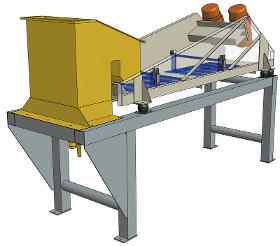

Designed for your operators for a complete visual inspection and manual removal of waste mixed in with products.

Request for a quote

FEMIA INDUSTRIE

France

Sorts and calibrates products such as strawberries/lemon/cauliflower/broccoli up to 4 grades. The vibrating unit is designed to remove the particles and very small pieces of products and allows for an ideal spreading of the latter. A hopper under the vibrating part can be adjusted in order to adapt to 4 grades of your products.

Request for a quote

FEMIA INDUSTRIE

France

With the production of deep frozen products, calibration and even sorting can be required aiming for global optimisation of the process and of the storage of the products as well as of their quality. At this step in your production, FEMIA offers various process functions that can be used after deep freezing, such as cleaning, calibration and sorting. Our solutions allow you to effectively sort products according to their grade (peas, cauliflower, broccoli or cut vegetables in particular) in order to limit intermediate storage and the management thereof before deep freezing. Thanks to the sorting and calibration post deep freeze, you can store your deep frozen products in bulk in large containers and pack them as your orders come in, in order to smooth out your production flows.

Request for a quote

FEMIA INDUSTRIE

France

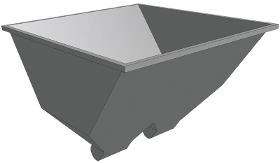

Allows for storage after cleaning (optionally after calibration) of varied granular product. (peas, flageolet beans, broad beans, white/red beans, chickpeas, lentils etc.) and products that are difficult to handle such as sweet corn. Gentle and facilitated removal of products via its upper and lower hoppers. Optimum and controllable extraction at hopper output via its electromagnetic vibrating distributor.

Request for a quote

FEMIA INDUSTRIE

France

Allows for storage after cleaning (optionally calibration) varied granular products (peas, flageolet beans, broad beans, white/red beans, chickpeas, lentils etc.) Fully adjustable flow for a steady flow of your products at the output. We also offer sealed hopper models that allow for static soaking of dry vegetables. To adapt to your needs, our hoppers are available in different formats.

Request for a quote

FEMIA INDUSTRIE

France

In a fruit or vegetable processing line, storage is often required to feed the line, process the various categories of products and smooth out the flows between the different machines as well as in case of stoppage of the production line.Feed hoppers that depend on the Product Product transport mode or the container The production capacity of the line Buffer hoppers with adjustable feed system.

Request for a quote

FEMIA INDUSTRIE

France

Transfers and feeds the product in a piece of equipment located downstream. Adapted according to your needs and your production.

Request for a quote

FEMIA INDUSTRIE

France

According to your needs, transfers and/or elevates products to a machine located downstream. Can be adapted according to your needs and capacities. Increased reliability thanks to its stainless steel structure. Better preservation of the product thanks to its plates with or without plastic flights.

Request for a quote

FEMIA INDUSTRIE

France

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

FEMIA INDUSTRIE

France

Transfers and lifts the clean product from one piece of equipment to a piece of equipment at a higher level. Several scraper widths are available according to the capacity of the product to be transferred. Adapted to low mass products Adapted to the architecture of the line and to the constraints of the building.

Request for a quote

FEMIA INDUSTRIE

France

Transfers and lifts the product from one piece of equipment to a piece of equipment at a higher level. Adapted to granular products (e.g. peas). Several bucket widths and depths are available according to the capacity of the product to be transferred. Adapted to the architecture of the line and to the constraints of the building.

Request for a quote

FEMIA INDUSTRIE

France

Transfers varied small size products in a flow of water propelled by a pump Ideal for long distance transfers. Characteristics of the hydraulic circuit (length, elevation pressure head, etc.) depending on the required product flow rates.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEMIA INDUSTRIE

France

The conveyor provides the product transfer to the machine located downstream. The distributor evenly and continuously transfers your products to several machines downstream. Several outlets and fully adjustable deflector flaps guarantee ideal distribution of your products between the various outlets. Can be adapted and customised according to your needs and capacities (length, width, number of outputs).

Request for a quote

FEMIA INDUSTRIE

France

Conveying is an important element in the performance of your production lines with the dual challenge of limiting product degradation and losses as well as the proper feed on to the downstream machine, an essential point for optimum performance.Belt conveyor, vibrating conveyor, flighted belt elevators, scraper or bucket elevators, hydraulic transporters, we can adapt many conveying solutions to your lines. Our conveying systems must be selected according to the architecture of the preparation line and products processed in order to represent the solution that will provide you with the best performance and meet the particular challenges of your production.In addition to the diversity of the machines that we can apply to your line, our know how resides in our ability to adapt to your needs. We propose a solution that aims to optimise the layout for a minimum amount of space occupied while still including the maintenance constraints.

Request for a quote

FEMIA INDUSTRIE

France

Precise control of the parameters and homogeneous processing of the product by maintaining the temperature through the entire thickness of the product layer for the time required for blanching (and even pre cooking) the processed products. High material yield by preserving as best as possible the organoleptic qualities of the processed products. Minimum water consumption according to the operating mode selected. Optimisation of the dimensions of the equipment according to the range of products to be processed and of the space constraints of the installation zone.

Request for a quote

FEMIA INDUSTRIE

France

Blanching, pre cooking, cooling… continuous thermal treatments are our other expertise. Stopping enzymatic activity, de aerating products, setting their colour, retaining as much as possible the Brix degrees and flavours; those are all of the challenges in thermal treatments of products in tins preserved or deep frozen with an objective of food quality and safety. We offer a large choice of machines that are designed for the better answer to the customer application which also depend on their quality and operating cost targets. Our blanchers, blancher coolers and coolers are designed and sized for the need according to the products to be processed; according to whether it entails tins preserved or deep frozen food products. designed for the required capacity; dimensions are defined on a case by case basis (length / width). This equipment makes it possible to blanch in hot water mode and/or in steam mode and/or in mixed mode; cool in water and/or cold water and/or air mode.

Request for a quote

FEMIA INDUSTRIE

France

Sorting and calibrating of products such as strawberry/lemon/flower cabbage with 4 sizes. Mobile product thanks to its 4 removable feet. The vibrating unit is designed to eliminate small product breakages and allow ideal spreading of the products. A hopper under the vibrating element is adjustable to adapt to 4 calibers of your products.

Request for a quote

FEMIA INDUSTRIE

France

Cuts the ends of the green beans or products of similar shape,Machine primarily comprised of a drum with wave slots plastic segments for a clean and precise cut of the ends of green beans. Large range of plastic wave slots segments (slot width is to be selected according to the calibre of the green beans processed). Optional safety guards and cleaning in place system.

Request for a quote

FEMIA INDUSTRIE

France

Sorts granular products (peas, flageolet beans, etc.) by calibre (XF, TF, F, Medium for peas).Machine comprised primarily of a rotating drum with perforated plates and corresponding hoppers Length and diameter of the drum are customised according to the characteristics of the processed product and the calibres sought. Continuous clearing of the drum thanks to a scraper system. Possibility of adding belt conveyors and intermediate storage hoppers.

Request for a quote

FEMIA INDUSTRIE

France

Pulls off the husks of unprocessed ears of corn.Machine primarily comprised of a roller table, a vibrating feeder and of a variable speed conveyor with its hopper in the upper portion. The roller table is comprised of 4, 8, 12 or 16 “Lanes” keeping in mind that a “Lane” comprises 2 axes with rollers. Range of various husker rollers according to the variety of corn processed Regular feed thanks to a variable speed conveyor belt and a vibrator that aligns the ears before the roller table. Recovery of the husk and silk waste under the roller table.

Request for a quote

FEMIA INDUSTRIE

France

Saws the husked ears of corn into several pieces (1 to 3). Capacity (automatic feeding version) of 110 ears/minute with the ACC feed system of the cutter. Capacity (manual feeding version) of 60 ears/minutes with two operators. Machine primarily comprised of an automatic feed (automatic feeding version only), a roller conveyor and a cutting head with circular saws. For the two versions, an operator manages the orientation of the ears on the conveyor belt Roller conveyor for visual control and feeding the saw. Adjustment of the cutting of the ends of the ears and of the pieces for a desired length.

Request for a quote

FEMIA INDUSTRIE

France

Cuts husked ears of corn. Capacity of 60 ears/minute (according to the performance of the operator who is feeding the cutter). Machine primarily comprised of a cutting head with 6 blades arranged like a diaphragm of a camera. Self clearing of the cutter head in case of jams. The cutter requires the very specific WKS blade sharpener.

Request for a quote

FEMIA INDUSTRIE

France

This step represents a particular stake with regards to classifying products. Indeed, the diversity of shapes of the vegetables and formats desired at the outlet of the preparation line requires having available and choosing the right equipment in order to obtain the required product categories.Our offer is comprised of effective solutions that are particularly suitable for working with different types of fruits and vegetables. This step in the process is the critical step for the material yield of the preparation line. We thus propose various cutters that are especially suited for cutting corn but also cluster cutting, snipping and cross cutting of green beans. FEMIA has developed calibration solutions, which correspond to the particular requirements of the various types of vegetables. Femia drums and vibrators accurately select and class processed vegetables according to their size and can be adjusted in order to correspond precisely to the calibration standard sought.

Request for a quote

FEMIA INDUSTRIE

France

Special for spinach.Machine comprised pre washing and washing tanks, pumps that allow for the creation of turbulent flows, some insect trap and propeller to make the leaves plunging in the turbulent bath. Recovery of the water in a settling tray at the outlet of the washer and filtering of the water with a wire rotating drum and its scraper in order to separate the waste. Circulation of water in a closed loop for low water consumption.

Request for a quoteResults for

Conveyor systems - Import exportNumber of results

368 ProductsCountries

Company type

Category

- Conveyor systems (180)

- Conveyor belts (60)

- Food industry - machinery and equipment (15)

- Storage equipment and systems (8)

- Bottling and filling - machinery and equipment (6)

- Motor mechanics - hand tools, non power (6)

- Automation - systems and equipment (5)

- Goods handling systems, continuous (5)

- Gears (4)

- Inductive sensors (4)

- Labelling machines (4)

- Plastics - machines and material for industry (4)

- Flour-milling (3)

- Laser - cutting and welding machines (3)

- Machine tools, metal shaping - parts and accessories (3)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Conveyors, overhead and floor (2)

- Cooking and smoke-curing equipment for delicatessens (2)

- Foods, precooked and gourmet (2)

- Grids, gratings and wire mesh (2)