- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging materials

Results for

Packaging materials - Import export

IGUS® GMBH

Germany

iglidur® knife edge rollers Precise and lubricant-free deflection igus® has developed its own knife-edge conveyor pulleys to implement conveyor belt deflection for conveyor technology applications. The first standard product range has three iglidur® materials available: the universal iglidur® P210 and the FDA compliant iglidur® A180 (up to 90°C) and iglidur® A350 (up to 180°C). The iglidur® solution is characterized by tight deflection radii and low essential driving power. Complete freedom from the lubricant of the belt deflection Low driving power Tight deflection radii Long service life of the belt Cost-effective High holding times Application areas: Packaging, material handling, automation, food processing. Brochure (PDF) Shaft diameter d1 [mm]: Knife-edge conveyor pulley application example Precise and lubricant-free deflection igus® has developed its own knife-edge conveyor pulleys to implement conveyor belt deflection for conveyor technology applications. The first standard product range has three iglidur® materials available: the universal iglidur® P210 and the FDA compliant iglidur® A180 (up to 90°C) and iglidur® A350 (up to 180°C). The iglidur® solution is characterized by tight deflection radii and low essential driving power. Complete freedom from the lubricant of the belt deflection Low driving power Tight deflection radii Long service life of the belt Cost-effective High holding times Application areas: Packaging, material handling, automation, food processing. Brochure (PDF) Shaft diameter d1 [mm]: Soft stainless steel Hard stainless steel

Request for a quote

FATRA A.S.

Czech Rep.

Technical BOPET films Biaxially oriented polyethylene terephthalate (BOPET) films Fatra Tenolan® are extruded films with subsequent biaxial orientation. Films are designed for further processing in electro-technical industry, for decoration purposes, as separation foils, etc. They are supplied in rolls or cut to size. Processed materials PET Al PET (polyethylene-terephthalate) is a hard and clear polymer material with extremely good mechanical features. It shows excellent tear resistance; it can resist to high pressure volumes without braking, which is used in the production of packages for beverages – PET bottles. PET material is suitable also for the production of extruded foils. Subsequent biaxial stretching of the foil (in both directions) improves significantly the strength in both directions. It forms the required packaging material known for example from gift packs, or as a baking foil. In the foil form, PET is very resistant against water steam and gas permeability...

Request for a quote

FATRA A.S.

Czech Rep.

Packaging laminates Multi-layer laminated foils Fatra Folam® are designed mainly for the production of so-called flexible packages. These areal materials are mostly of foil type and their basic layer is formed by BOPET film. Processed materials PET paper PE PP Al PET (polyethylene-terephthalate) is a hard and clear polymer material with extremely good mechanical features. It shows excellent tear resistance; it can resist to high pressure volumes without braking, which is used in the production of packages for beverages – PET bottles. PET material is suitable also for the production of extruded foils. Subsequent biaxial stretching of the foil (in both directions) improves significantly the strength in both directions. It forms the required packaging material known for example from gift packs, or as a baking foil. In the foil form, PET is very resistant against water steam and gas permeability providing protection to packaged products, it also resists to effects of oils and fats...

Request for a quote

FATRA A.S.

Czech Rep.

Plastic crate Plastic crate produced with injection moulding technology – primarily intended for use: In households. In food industry – for pastries, fruits and vegetables. Processed materials PP HDPE PP (polypropylene) is the second most frequently used material in Europe. Its share in consumption of plastic materials ranges about 20 %. Polypropylene is By its features and use, polypropylene is similar to polyethylene, therefore both of these polymers are classified in the same group indicated as polyolefins. Unlike PE, PP however features higher strength and consistency, and since its melting temperature is higher, it shows good temperature stability. PP consistency imparts good dimensional stability to products. Polypropylene can be found almost anywhere: in packaging materials, household appliances, clothing, means of transport, and many other products. More than half of the world PP production is used for packages. It is also used in technical applications. It is used...

Request for a quote

FATRA A.S.

Czech Rep.

BOPET films Biaxially oriented polyethylene terephthalate (BOPET) films Fatra Tenolan® are extruded films with subsequent biaxial orientation. Films are designed for further processing in the packaging technology, electro-technical industry, for decoration purposes, as separation foils, etc. They are supplied in rolls or cut to size. Films are designed for direct contact with food and meals and they must comply with hygienic regulations in force. Processed materials PET Al PET (polyethylene-terephthalate) is a hard and clear polymer material with extremely good mechanical features. It shows excellent tear resistance; it can resist to high pressure volumes without braking, which is used in the production of packages for beverages – PET bottles. PET material is suitable also for the production of extruded foils. Subsequent biaxial stretching of the foil (in both directions) improves significantly the strength in both directions. It forms the required packaging material known for...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLIFILM

Belarus

Polyethylene tubular film is a packaging material that is a tube or sleeve made of polyethylene. This type of film is widely used in various industries due to its versatility and ease of use. Here are some of its characteristics and applications: Characteristics of polyethylene sleeve film: Elasticity: Polyethylene tubular film has good elasticity and stretchability, making it an ideal material for packaging products of various sizes and shapes. Transparency: Depending on the type of polyethylene, tubular film can be transparent or opaque. Transparent options allow you to see the contents of the package without having to open it. Protection from dust and moisture: Sleeve film provides good protection of goods from dust, dirt and moisture, which is important during their transportation and storage.

Request for a quote

POLIFILM

Belarus

Cling film is a soft, transparent, flexible and at the same time stretchy packaging material. Used for packaging meat, fruits, cheeses, bread, flour, and confectionery products. It has excellent breathability, is resistant to fats and extends the shelf life of fresh goods. Due to the elastic effect, the stretch film tightly fits the product, fixing it on a solid tray or substrate. Thanks to the qualities possessed by this type of film, the product retains its conditioned appearance for a long time, does not dry out, and prevents weathering. This solution definitely takes place in industrial food packaging; cling film is often used in the restaurant and gastronomic business.

Request for a quote

POLIFILM

Belarus

Recycled stretch film is a packaging material made from recycled materials, making it more environmentally friendly. The main application of this film is associated with manual packaging, where the use of primary stretch film is not required and there is no need for increased rigidity. Features of recycled stretch film: Eco-Friendly Material: Recycling the materials used to produce this film reduces the negative impact on the environment as reusing the material reduces the need for new resources. Ease of use: Recycled stretch film has good elasticity and adhesiveness, which ensures simplicity and reliability of the packaging process. Application in various industries: Recycled stretch film can be used in various industries, such as logistics, retail, warehousing and others, where reliable packaging of goods is required without the use of virgin film.

Request for a quote

DDC - DUTCH DESICCANTS COMPANY (CANADACO B.V.)

Netherlands

Din Dry products can be used in a wide variety of environments. We offer solutions for e.g.: Industrial solutions Packaging for machines Packaging for military products and tools (meets applicable quality standards) Suitable for use inside transport crates Transport of military and industrial products Leather products Electronic equipment Airfreight The use of KINDRY desiccants is advised when reliable high-grade protection against moisture is needed. A desiccant for industrial environments in accordance with the DIN 55 473 and military standards MIL-D-3464E. This is particularly important for protective packaging materials that must be durable and capable of withstanding different climate conditions, as is the case with classical export packagings.

Request for a quote

PACK HOUSE EGYPT

Egypt

Plastic bags are highly versatile and convenient packaging materials widely utilized across industrial and commercial sectors. They play a crucial role in preserving the hygiene and quality of raw materials and finished products, simplifying transportation and distribution processes within factories and between sellers and buyers

Request for a quote

PACK HOUSE EGYPT

Egypt

Polyethylene film, available in high or low density variants, is a plastic packaging material widely employed across diverse industrial sectors to safeguard goods against damage or contamination. It also finds application in agriculture, construction, printing, and food packaging.

Request for a quote

GALATA PACK

Turkey

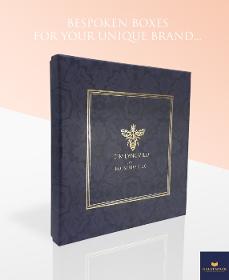

We supply high quality fashion packaging materials.

Request for a quoteResults for

Packaging materials - Import exportNumber of results

13 ProductsCompany type